Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

A manufacturing method and magnesium alloy technology, applied in the field of heat-resistant and corrosion-resistant magnesium alloys, heat-resistant and corrosion-resistant magnesium alloys, can solve the problems of poor corrosion resistance of heat-resistant magnesium alloys, etc., to improve creep resistance and plasticity , Improve the effect of precipitation strengthening, improve the effect of mechanical and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

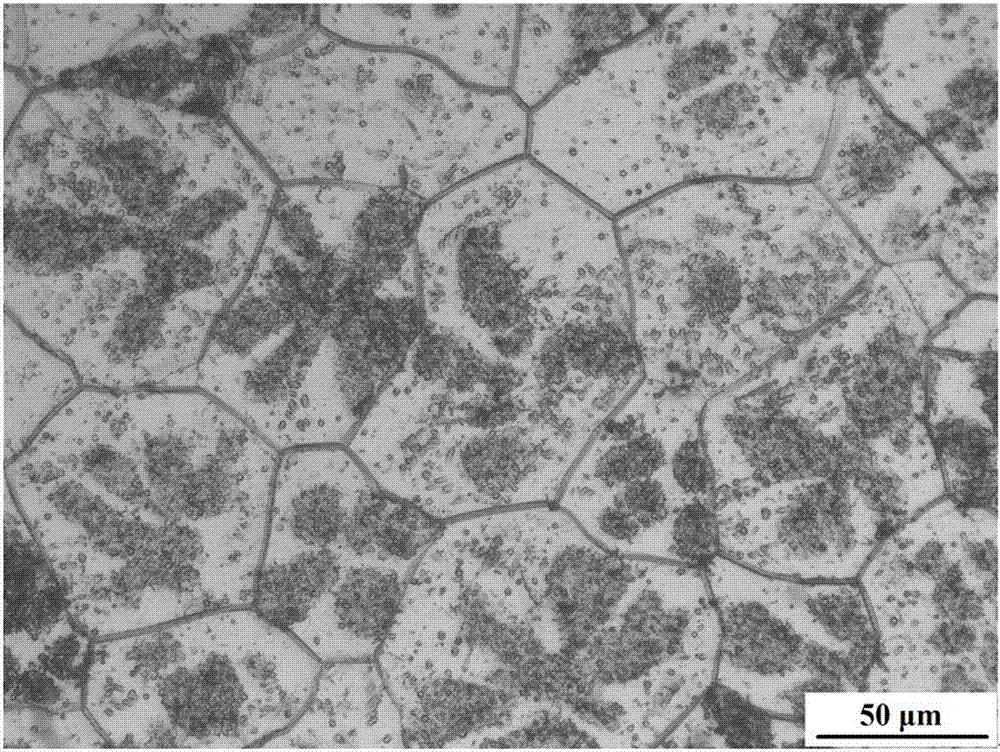

Embodiment 1

[0027] The manufacture method of the multi-component reinforced heat-resistant and corrosion-resistant magnesium alloy of the present invention comprises the following steps in turn: (1) preparing ingredients: comprising pure magnesium ingot, pure zinc ingot, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg- Ca alloy, Mg-Zr alloy and nano-scale NdN particles, the mass percentage content of each element in the raw material is as follows, Gd: 3.5%, Y: 1.0%, Nd: 0.5%, Zn: 0.8%, Ca: 0.3%, Zr : 0.3%, nano-scale NdN particles: 0.5%, the balance is Mg, wherein the mass percentages of the three rare earth elements Gd, Y and Nd are Gd>Y>Nd in descending order, and Gd, Y and Nd The mass fraction of the total addition of the three rare earth elements does not exceed 10%, and the particle size of the nanoscale NdN particles is 80nm.

[0028] (2) Pretreatment and coating of nano-scale NdN particles: Soak nano-scale NdN particles in a mixed acid solution made of hydrofluoric acid, hydrochloric acid...

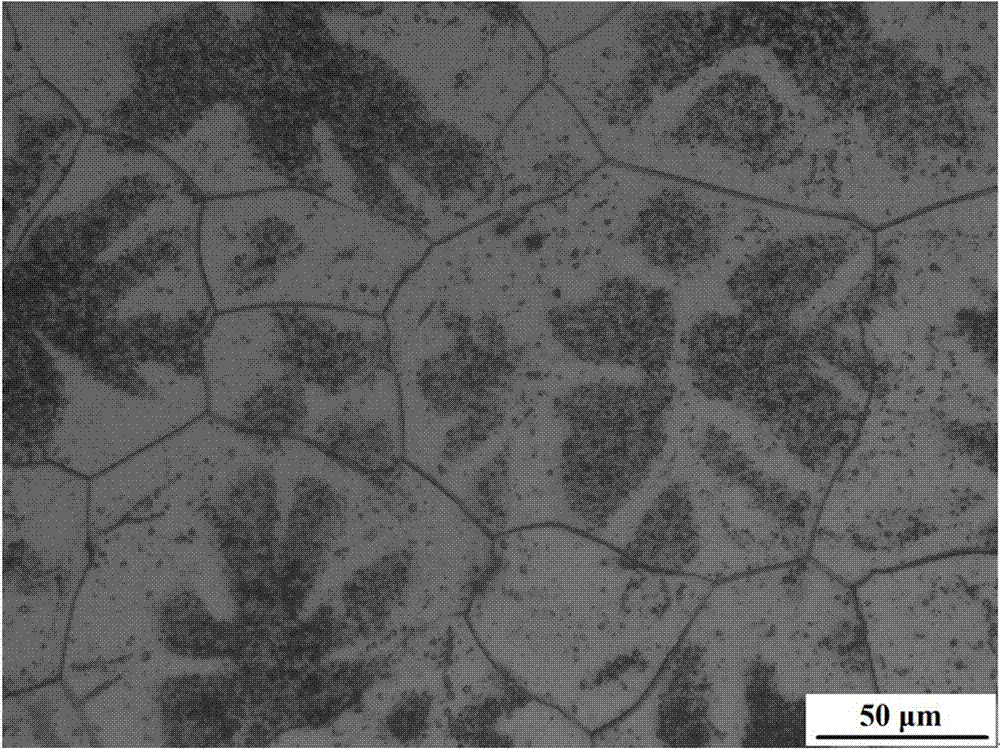

Embodiment 2

[0040] The manufacture method of the multi-component reinforced heat-resistant and corrosion-resistant magnesium alloy of the present invention comprises the following steps in turn: (1) preparing ingredients: comprising pure magnesium ingot, pure zinc ingot, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg- Ca alloy, Mg-Zr alloy and nano-scale NdN particles, the mass percentage content of each element in the raw material is as follows, Gd: 4.2%, Y: 2.0%, Nd: 0.7%, Zn: 1.2%, Ca: 0.5%, Zr : 0.4%, nanoscale NdN particles: 1.0%, and the balance is Mg, in which the mass percentages of the three rare earth elements Gd, Y, and Nd are in the order of Gd>Y>Nd, and Gd, Y, and Nd The mass fraction of the total addition of the three rare earth elements does not exceed 10%, and the particle size of the nanoscale NdN particles is 120 nm.

[0041] (2) Pretreatment and coating of nano-scale NdN particles: Soak nano-scale NdN particles in a mixed acid solution prepared by hydrofluoric acid, hydrochlo...

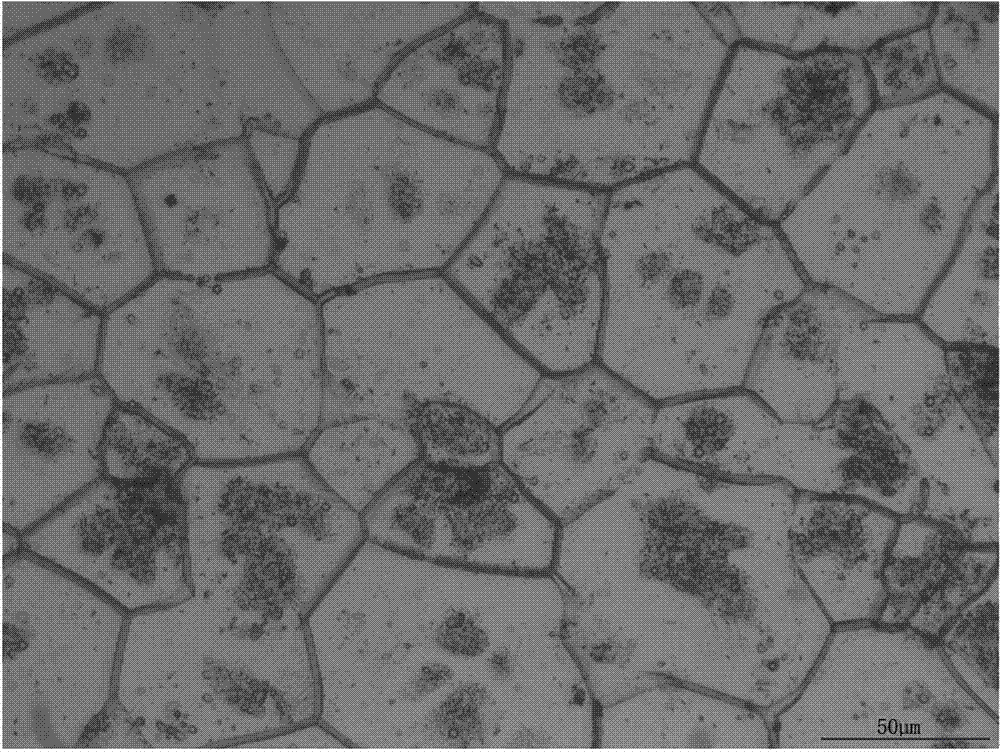

Embodiment 3

[0053] The manufacture method of the multi-component reinforced heat-resistant and corrosion-resistant magnesium alloy of the present invention comprises the following steps in turn: (1) preparing ingredients: comprising pure magnesium ingot, pure zinc ingot, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg- Ca alloy, Mg-Zr alloy and nano-scale NdN particles, the mass percentage content of each element in the raw material is as follows, Gd: 5.0%, Y: 3.0%, Nd: 0.8%, Zn: 1.5%, Ca: 0.8%, Zr : 0.6%, nano-scale NdN particles: 1.5%, the balance is Mg, wherein the mass percentage content of the three rare earth elements Gd, Y and Nd is Gd>Y>Nd in descending order, and Gd, Y and Nd The mass fraction of the total addition of the three rare earth elements does not exceed 10%, and the particle size of the nanoscale NdN particles is 150 nm.

[0054] (2) Pretreatment and coating of nano-scale NdN particles: Soak nano-scale NdN particles in a mixed acid solution prepared by hydrofluoric acid, hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com