Truss type ultralight overall wing structure

A wing structure and truss-type technology, applied in the direction of wings, aircraft parts, chords/stringers, etc., can solve problems such as difficult to achieve weight index requirements, obvious overweight, etc., achieve obvious weight reduction benefits and reduce structural weight , the effect of higher than the stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention.

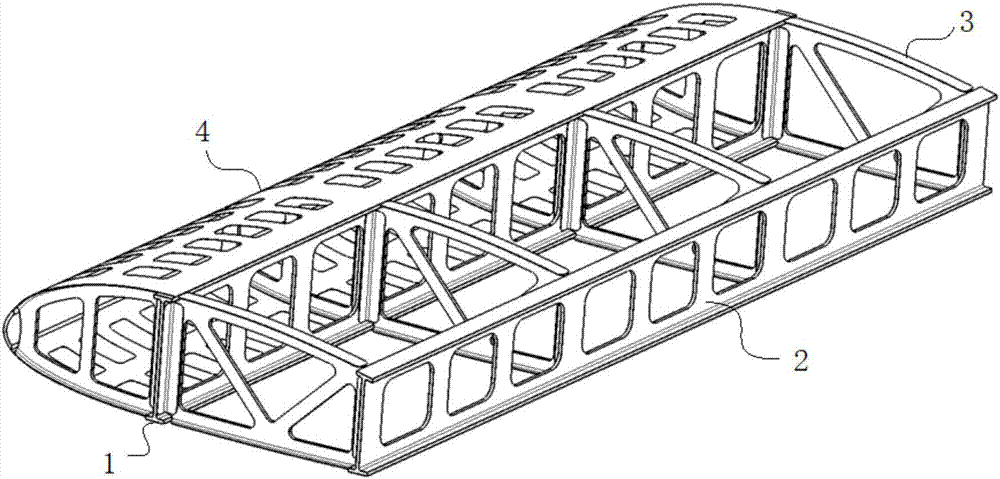

[0030] Aiming at the characteristics of low-speed small wing loads of near-space unmanned aerial vehicles, the present invention proposes a truss-type ultra-light integral wing structure design scheme, which adopts a new layout method of "film skin-sandwich skeleton", and the entire wing structure It mainly includes front beam 1, rear beam 2, wing rib 3, hard skin 4 and flexible skin 5, etc.

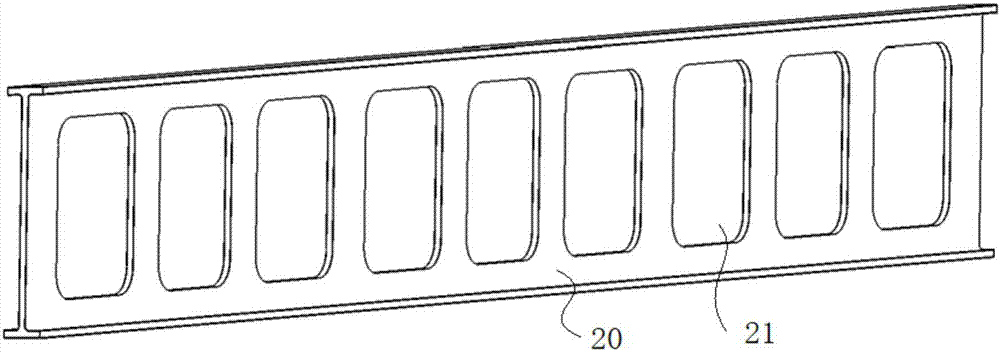

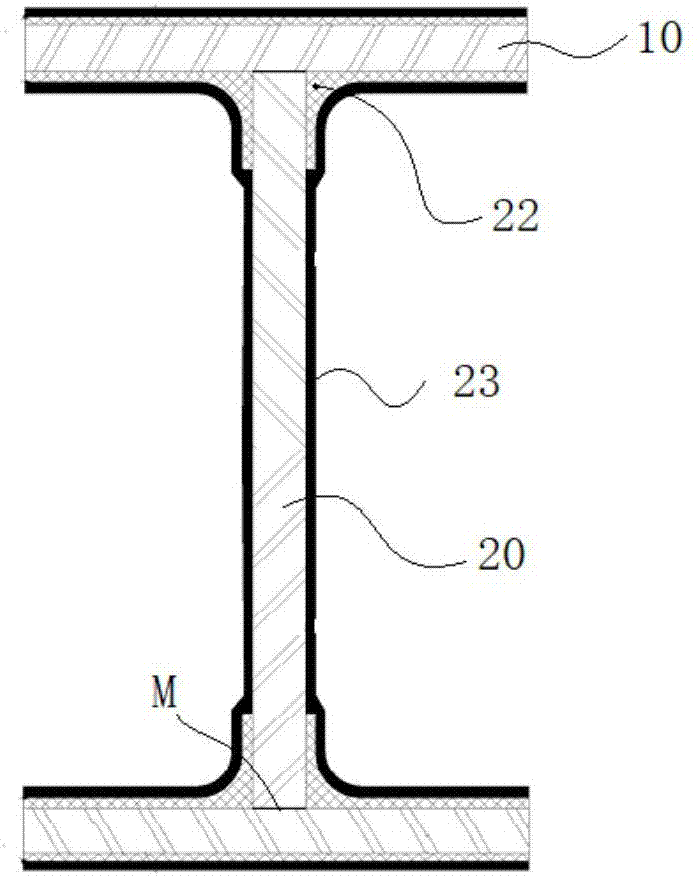

[0031] Such as figure 1 As shown, the spar is a span-wise component, which is divided into front spar 1 and rear spar 2. The front spar 1 is arranged in the area with high airfoil height, and the rear spar 2 is close to the trailing edge. The spar is the main load-bearing component of the wing. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com