Foamed aluminium / PC resin / aluminum alloy laminate composite material and preparation method thereof

A composite material and foamed aluminum technology, which is applied in the field of foamed aluminum/PC resin/aluminum alloy laminated composite material and its preparation, can solve the problems of long molding cycle, poor firmness, easy breakage, etc., and achieves high performance/price ratio, The effect of excellent impact performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

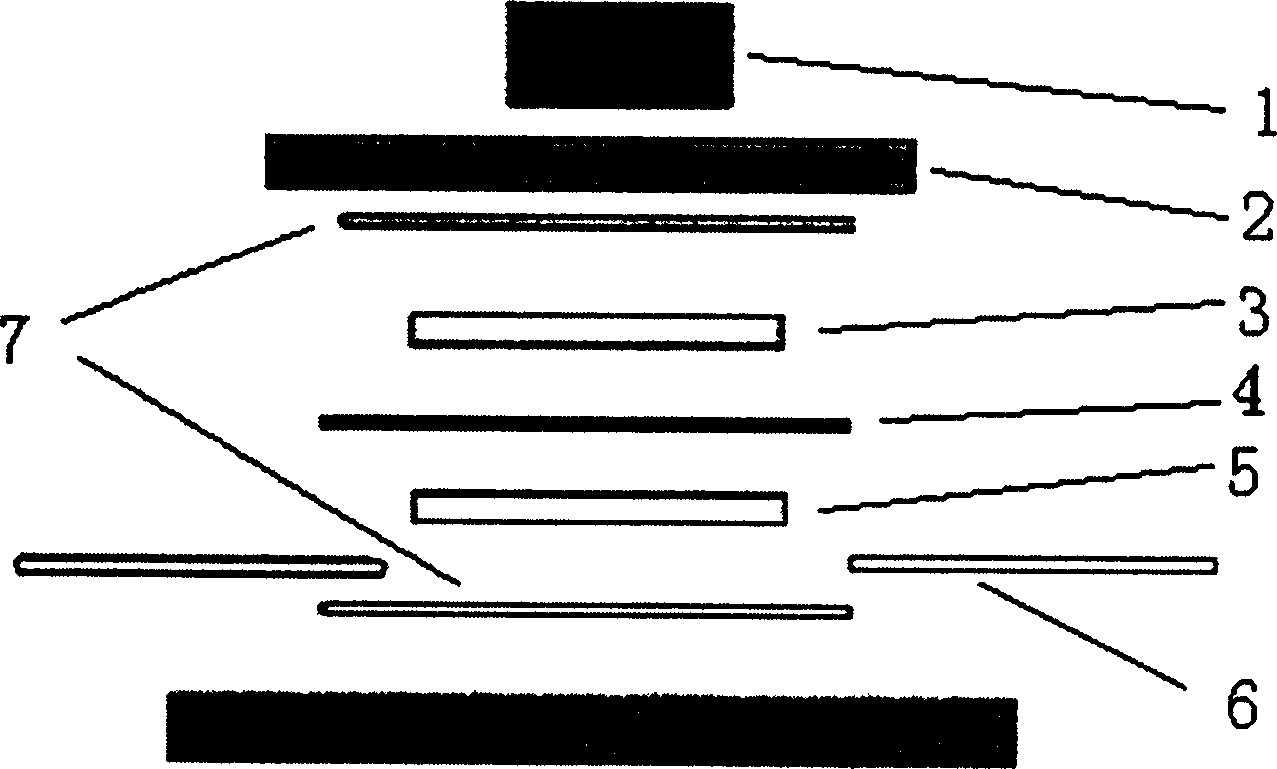

Image

Examples

Embodiment 1

[0022] 1. Aluminum alloy surface treatment:

[0023] Firstly, the surface of the aluminum alloy is shot-peened to obtain a rough surface; 2 CO 3 (40g / L) and Na 2 SiO 3 (20g / L) mixed aqueous solution for decontamination and lye degreasing treatment at a temperature of 70°C for 20 minutes to remove surface grease. The detection method for whether the degreasing time is sufficient or not is to see whether there are residual water drops or thin lines of water flow on the surface. Finally pickling etching treatment, solution formula: concentrated sulfuric acid: sodium dichromate: distilled water is 10:1:20, treat at 60°C for 10 minutes, then rinse with 60°C water, so as to obtain a dense surface oxide layer and Greater surface area. After the above process is completed, the surface etching depth of chromic acid pickling is about 3 μm.

[0024] 2. Aluminum foam surface treatment

[0025] The surface of the foamed aluminum can be decontaminated and degreased with lye. The dec...

Embodiment 2

[0029] 1. Aluminum alloy surface treatment and foamed aluminum surface treatment process are the same as in Example 1;

[0030] 2. Thermoforming

[0031] After the surface treatment is completed, use LY12 aluminum alloy plate, PC resin, and foamed aluminum as raw materials, according to the thickness ratio of aluminum alloy plate / foamed aluminum of 1:5, and the PC resin is subject to filling, and the hot pressing process is carried out. As follows: Place the components of the composite material overlappingly according to the above scheme, heat to 240°C at a rate of 8°C / min, pressurize at the same time, the pressure is 4500N / m2, and keep warm at this temperature for 30 minutes; Heating at a speed of ℃ / min to 265°C; holding at 260°C for 25 minutes, the pressure remains unchanged; after the holding is completed, cool with the furnace.

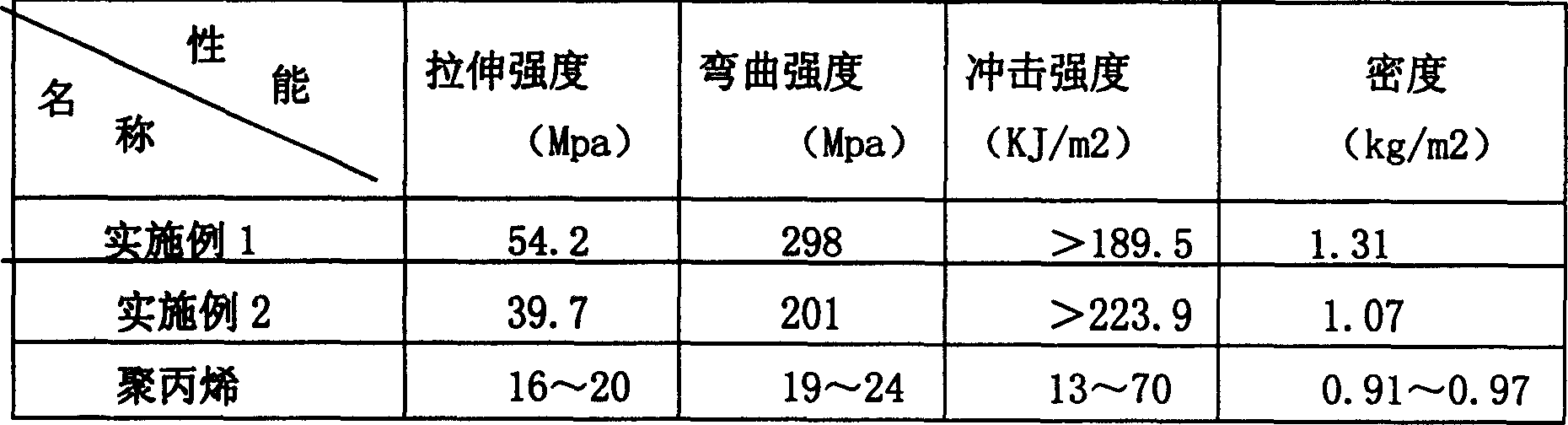

[0032] The embodiment of the present invention and the performance parameter comparison of polypropylene material are as shown in table 1:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com