High-impact-resistance high-flowability ABS resin and preparation method thereof

An ABS resin and high-flow technology, applied in the field of high-impact high-flow ABS resin and its preparation, can solve the problems that the flow performance can not be greatly improved, reduce the mechanical properties of ABS resin, etc., and achieve increased adhesion, Superior impact performance, long residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

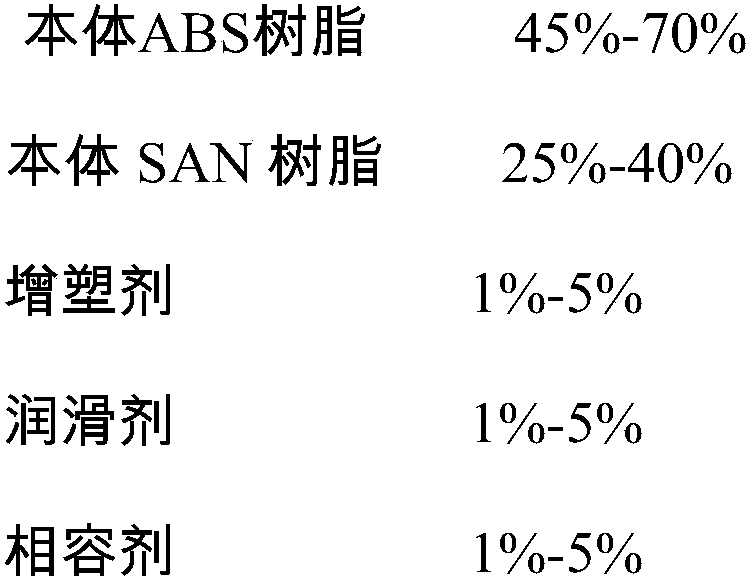

Method used

Image

Examples

Embodiment 1-3

[0030] Add the bulk ABS resin 8434, SAN resin, plasticizer, lubricant and compatibilizer into the mixer according to the ratio in Table 1 and mix thoroughly to obtain the mixed material; then send the obtained mixed material into the twin-screw extruder , for mixing, extrusion, strand drawing, cooling, and pelletizing, wherein the screw speed is 500rmp, the temperature of the head is 210°C, the temperature of the front section of the barrel is 200-230°C, the temperature of the middle section is 200-240°C, and the temperature of the rear section is 200-230°C ℃.

[0031] Table 1: Embodiment 1-3 concrete each material composition ratio

[0032]

Example 1

Example 2

Example 3

ABS resin 8434

55%

60%

65%

SAN resin

37%

32%

27%

3%

3%

3%

2%

2%

2%

Compatibilizer

3%

3%

3%

[0033] Table 2: Test results of various physical properties of the ABS resin prepared in ...

Embodiment 4-6

[0036] Add the bulk ABS resin 3504, SAN resin, plasticizer, lubricant and compatibilizer into the mixer according to the ratio in Table 1 and mix thoroughly to obtain the mixed material; then send the obtained mixed material into the twin-screw extruder , for mixing, extrusion, strand drawing, cooling, and pelletizing, wherein the screw speed is 500rmp, the temperature of the head is 210°C, the temperature of the front section of the barrel is 200-230°C, the temperature of the middle section is 200-240°C, and the temperature of the rear section is 200-230°C ℃.

[0037] Table 3: Embodiment 4-6 concrete each material composition ratio

[0038]

Example 4

Example 5

Example 6

ABS resin 3504

55%

60%

65%

SAN resin

37%

32%

27%

plasticizer

3%

3%

3%

lubricant

2%

2%

2%

Compatibilizer

3%

3%

3%

[0039] Result table 4: each physical property test of the ABS resin prepared by embodimen...

Embodiment 7-9

[0042] Add the bulk ABS resin 8434, bulk ABS resin 3504, SAN resin, plasticizer, lubricant and compatibilizer into the mixer according to the ratio in Table 1 and mix thoroughly to obtain a mixed material; then send the obtained mixed material into Twin-screw extruder for kneading, extrusion, strand drawing, cooling, and pelletizing. The screw speed is 500rmp, the head temperature is 210°C, the front section temperature of the barrel is 200-230°C, the middle section temperature is 200-240°C, and the rear section temperature is 200-240°C. The section temperature is 200-230°C.

[0043] Table 5: Embodiment 7-9 concrete each material composition ratio

[0044]

Example 7

Example 8

Example 9

ABS resin 8434

40%

30%

20%

ABS resin 3504

20%

30%

40%

SAN resin

32%

32%

32%

plasticizer

3%

3%

3%

lubricant

2%

2%

2%

Compatibilizer

3%

3%

3%

[0045] Table 6: Test results of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com