Manufacture method of titanium or titanium alloy laryngotracheal interventional stent

A technology of titanium alloy and laryngotracheal tube, which is applied in the field of preparation of titanium or titanium alloy laryngotracheal stent, can solve the problems of poor flexibility of tracheal stent, difficult to obtain microporous structure, easy powder falling off, etc., and achieves easy control of processing size and shape. , good cleaning effect, fast processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

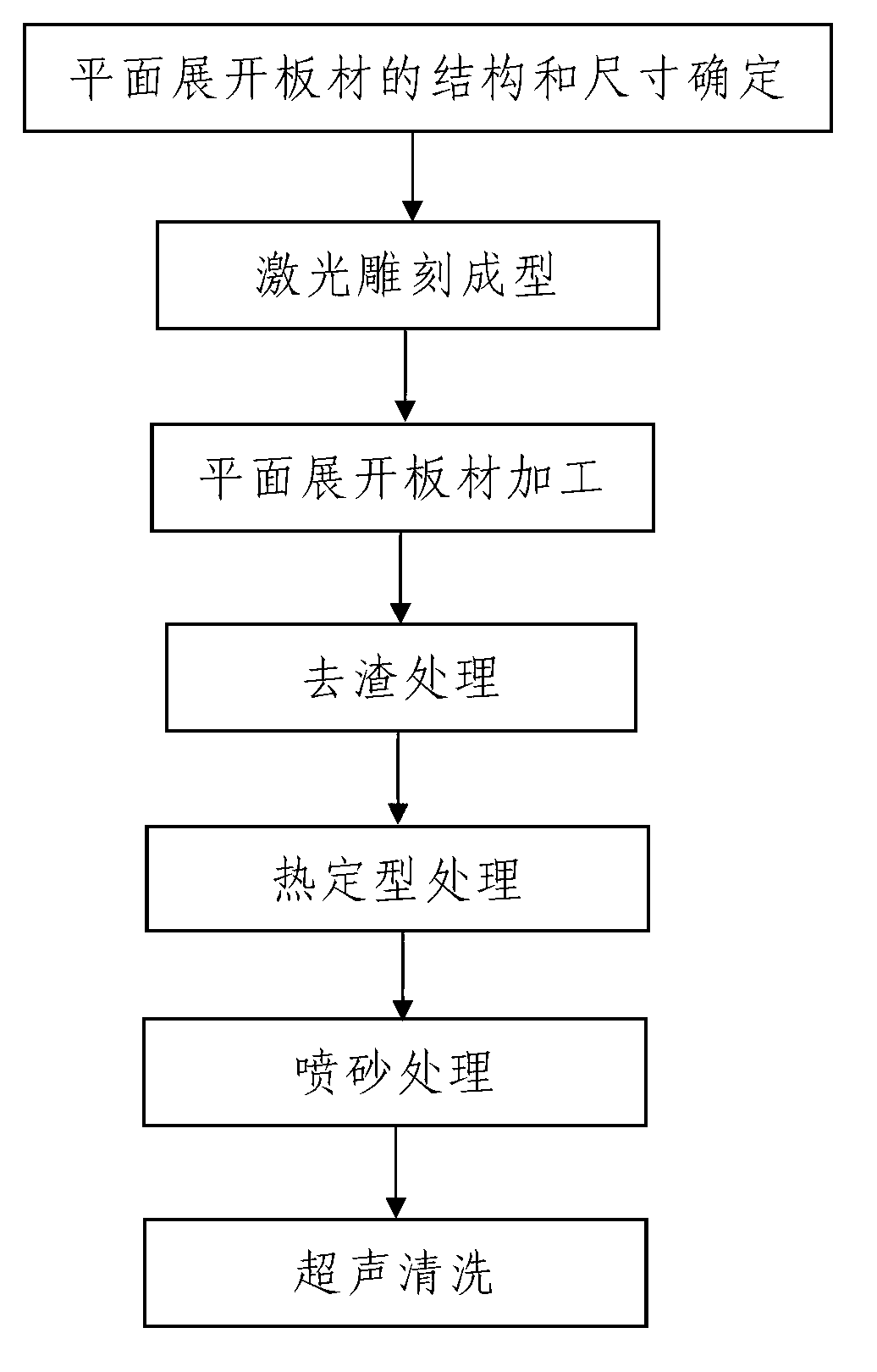

[0037] Such as figure 1 The shown method for preparing a titanium or titanium alloy laryngotracheal interventional stent includes the following steps:

[0038] Step 1. Determine the structure and size of the plane expansion plate: the plane expansion plate of the laryngotracheal interventional stent to be processed is a whole plate, and the structure and size of the plane expansion plate are determined according to the structure and size of the laryngotracheal interventional stent to be processed .

[0039] Step 2. Laser engraving and forming: first import the pre-designed and drawn micro-hole structure pattern to be engraved into the laser engraving machine; then, under the protection of inert gas, use the laser engraving machine to perform laser engraving on the plate to be processed, and obtain the laser Carved and shaped plane plate; the plate to be processed is a pure titanium plate or a titanium alloy plate.

[0040] The laser output power of the laser engraving machine is 30...

Embodiment 1

[0051] In this embodiment, the preparation of the titanium or titanium alloy laryngotracheal interventional stent includes the following steps:

[0052] Step 1. Determine the structure and size of the plane expansion plate: the plane expansion plate of the laryngotracheal interventional stent to be processed is a whole plate, and the structure and size of the plane expansion plate are determined according to the structure and size of the laryngotracheal interventional stent to be processed .

[0053] In this embodiment, the shape of the flat-expanded plate is square, the length of the flat-expanded plate is 20mm, the width is 30mm and its thickness is 0.2mm, and the unevenness of the flat-expanded plate is 3mm / m.

[0054] Step 2. Laser engraving and forming: first import the pre-designed and drawn micro-hole structure pattern to be engraved into the laser engraving machine; then, under the protection of inert gas, use the laser engraving machine to perform laser engraving on the plat...

Embodiment 2

[0071] In this embodiment, the difference from embodiment 1 is: in step one, the length of the flat unfolded board is 100mm, the width is 80mm and its thickness is 0.5mm, and the unevenness of the flat unfolded board is 3mm / m; The sheet to be processed in step 2 is a Ti-6Al-4V titanium alloy sheet. In actual preparation, other types of titanium alloy sheets can also be used; the laser output power of the laser engraving machine is 45W, and the laser output frequency is 9000Hz. The pulse width of the output laser is 0.5ms; and when performing laser engraving, the distance between the laser emission port of the laser engraving machine and the etched surface of the flat unfolded sheet is 1.2mm, and the cutting speed is 150mm / min; The weakly acidic cleaning agent in step 4 is made of nitric acid, hydrofluoric acid, hydrogen peroxide and deionized water, uniformly mixed in a volume ratio of 5:1:1:3, and the laser engraved flat sheet , Put it in a weakly acidic cleaning agent for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com