Weather-resistant rust-proof water paint and preparing method thereof

A water-based coating and weather-resistant technology, which is applied in the direction of anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of damaging the performance of anti-rust paints, and achieve the effects of improving weather resistance, simple operation, and shielding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (mechanical method preparation):

[0028] Selection of equipment and materials: The high-energy stirring mill is a German-made Dresses superflow-12 mill, and the grinding medium is yttrium oxide-toughened zirconia balls with a particle size of 0.5 mm. The titanium dioxide can be anatase type, more preferably a mixture of rutile type and anatase type, and the proportion of anatase type titanium dioxide powder is preferably 40%-70%.

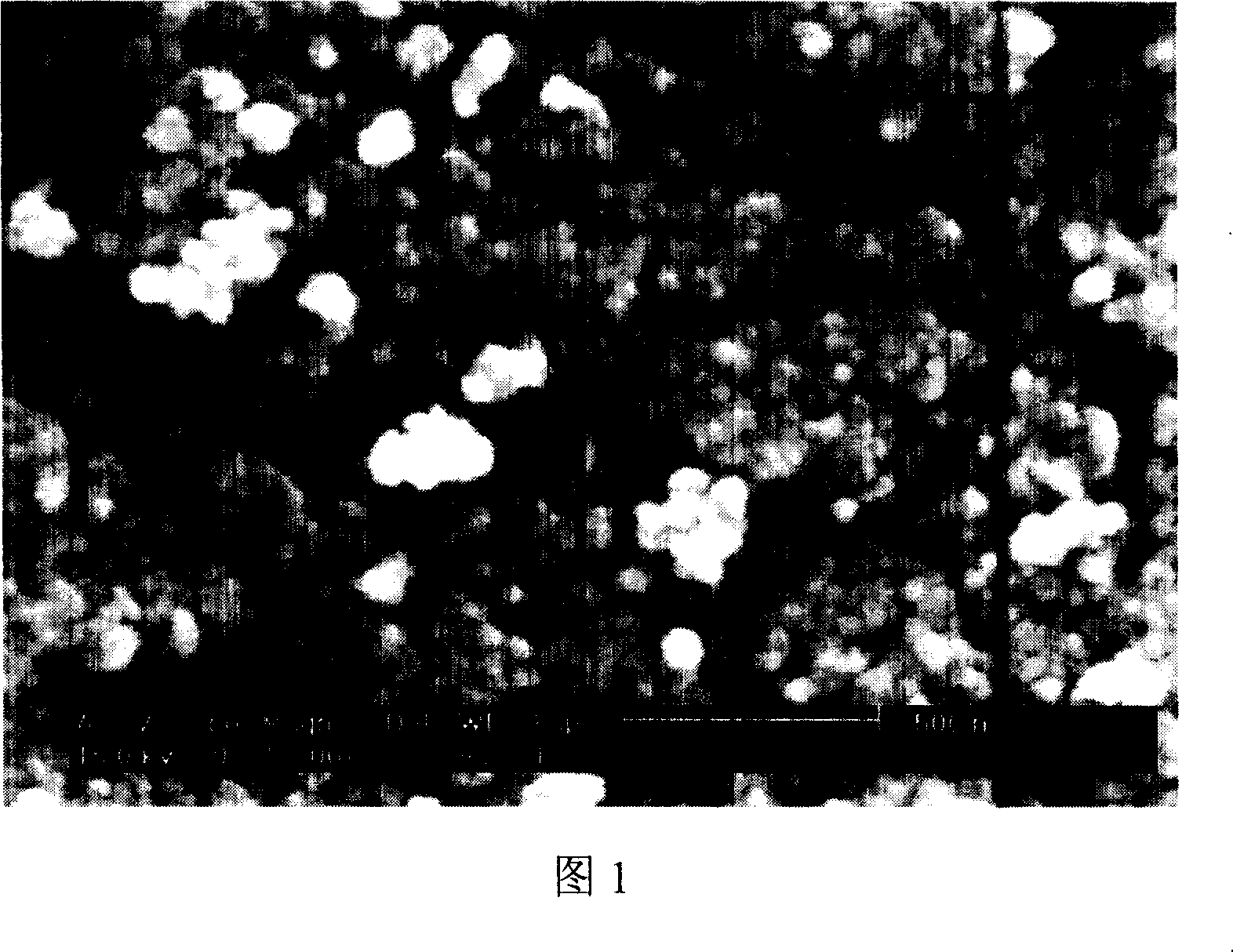

[0029] Process: First, measure 50 parts by mass of water according to the concentration of the prepared slurry and put it into a dispersion container, and then add 50 parts by mass of titanium dioxide that has been weighed. After dispersing with a disperser for about 10 minutes, turn on the superflow-12 mill, transport the slurry to the mill through a gear peristaltic pump, and circulate the slurry in the stirring mill for grinding. During the whole grinding process, the mixer was kept on, and the polyacrylic acid sodium salt d...

Embodiment 2

[0030] Embodiment 2 (alkali dissolution method):

[0031] Dissolve 10 parts by mass of titanium tetrachloride with 40 parts by mass of ice water to prepare a titanium tetrachloride solution with a certain concentration. Titrate this solution with ammonia water, and control the titration rate to about 100ml for 2 hours. During the titration process, a white precipitate is first formed, and then the precipitate disappears and then turns into a blue transparent sol. When the precipitate completely disappears, the titration process ends. Then add silicon dioxide precursor orthosilicate ethyl ester to the sol, the addition amount is converted into SiO 2 with TiO 2 The mass ratio is 2%. Stir to complete the encapsulation reaction, and obtain titanium dioxide colloids encapsulated by silica.

Embodiment 3

[0032] Embodiment 3 (acid-soluble method):

[0033]Take 20 parts by mass of titanium sulfate crystals, add them into 30 parts by mass of deionized water, stir and dissolve, and prepare a titanium sulfate solution. The excess sodium hydroxide solution with a mass fraction of 10% is added to the titanium sulfate solution to form a white precipitate of titanium hydroxide. Wash the precipitate with deionized water, filter, and peptize the precipitate with 5% hydrochloric acid solution to obtain a transparent sol. Then add silicon dioxide precursor orthosilicate ethyl ester to the sol, the addition amount is converted into SiO 2 with TiO 2 The mass ratio is 2%. Stir to complete the encapsulation reaction, and obtain titanium dioxide colloids encapsulated by silica.

[0034] The preparation embodiment of weather-resistant rust-proof water-based paint:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com