Semiconductor device

A semiconductor and bipolar transistor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as the deterioration of the current amplification rate of bipolar transistors, relieve thermal stress, and suppress thermal resistance. the increasing effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

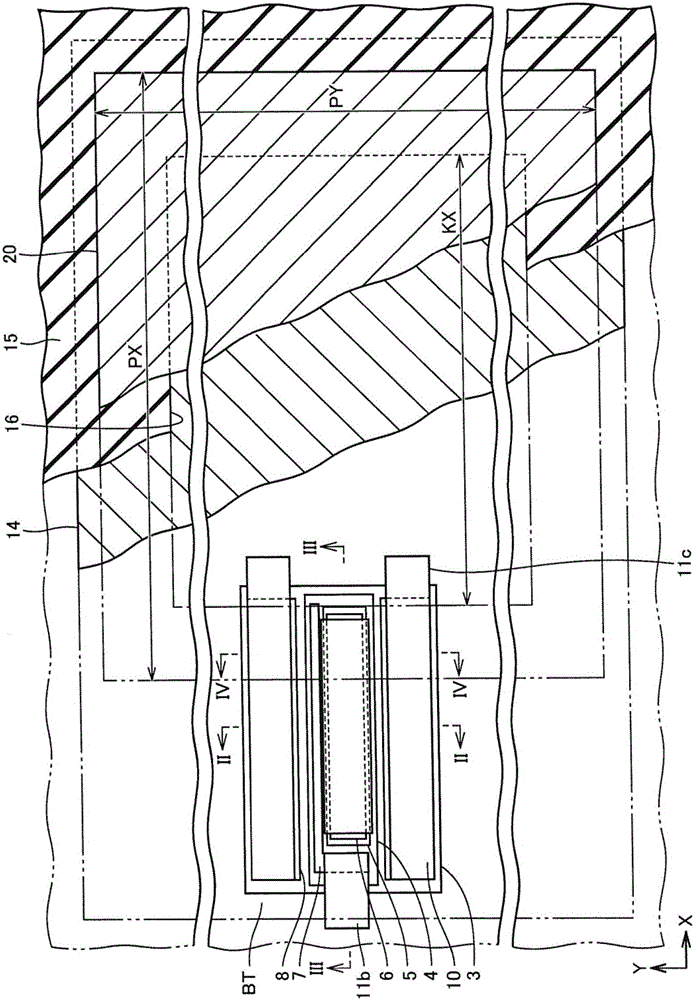

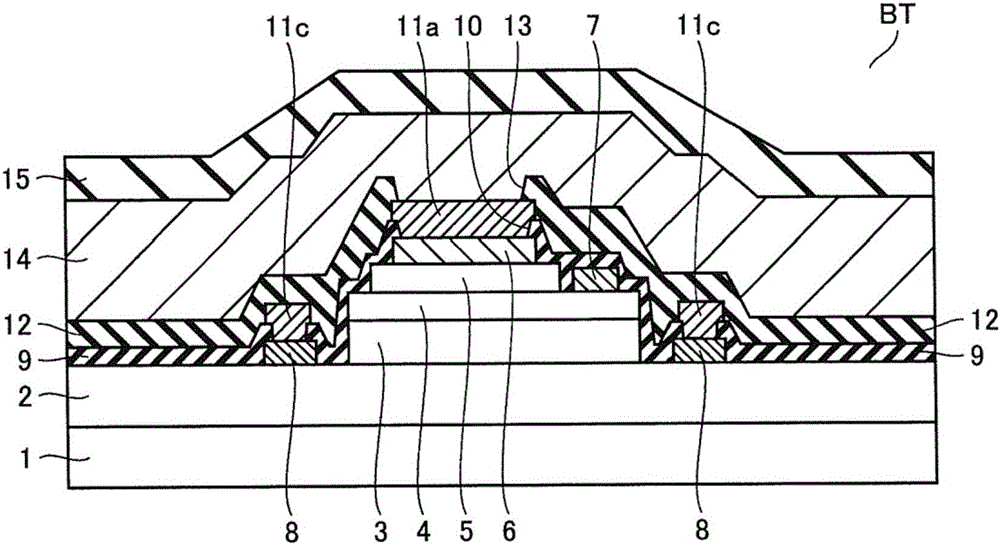

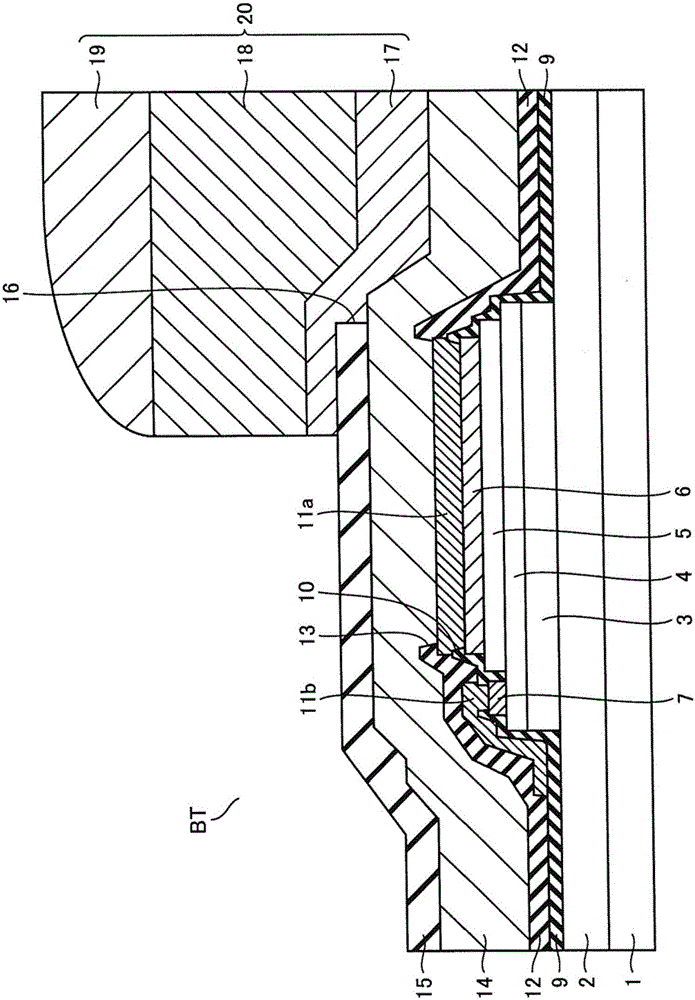

[0062] Here, a first example of a semiconductor device including a heterojunction bipolar transistor will be described.

[0063] Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, in a semiconductor device equipped with a bipolar transistor BT, the sub-collector layer 2 (n-type GaAs, Si concentration: 5×10 18 cm -3 , film thickness: 0.6 μm) is formed in contact with the surface of the semi-insulating GaAs substrate 1 . Form the collector layer 3 (n-type GaAs, Si concentration: 5×10 15 cm -3 , film thickness: 1.0 μm) is formed in contact with the sub-collector layer 2 . Base layer 4 (p-type GaAs, C concentration: 4×10 19 cm -3 , film thickness: 100 nm) is formed in contact with the collector layer 3 .

[0064] A mesa-shaped emitter layer 5 is formed in contact with the base layer 4 . The emitter layer 5 is stacked sequentially from the side of the base layer 4 with n-type In x Ga 1-x P layer (In composition ratio x=0.5, Si concentration: 3×10 ...

Embodiment approach 2

[0103] Here, as a second example of a semiconductor device including a heterojunction bipolar transistor, a semiconductor device in which rewiring is formed will be described.

[0104] Such as Figure 24 As shown, for example, a third insulating film 21 (film thickness: 10 μm) composed of a polyimide film or the like is formed to cover the passivation film 15 . A third opening 16 exposing the second wiring 14 is formed in the third insulating film 21 and the passivation film 15 . The third opening 16 is arranged with respect to the emitter layer 5 such that the end of the emitter layer 5 in the longitudinal direction almost coincides with the opening end of the third opening 16 (arrangement C).

[0105] A third wiring 23 (film thickness: 5 μm) made of a copper (Cu) film is formed as a rewiring so as to be in contact with the second wiring 14 exposed at the bottom of the third opening 16 and to be in contact with the opening along the third opening 16. The terminal is in contac...

Embodiment approach 3

[0113] Here, a modification of Embodiment 2 will be described as a third example of a semiconductor device including a heterojunction bipolar transistor.

[0114] Such as Figure 25 As shown, for example, a third insulating film 21 (film thickness: 10 μm) composed of a polyimide film or the like is formed to cover the passivation film 15 . The third opening 16 exposing the second wiring 14 (film thickness: 5 μm) made of a copper (Cu) film is formed in the third insulating film 21 and the passivation film 15 .

[0115] Then, the third wiring 23 as a rewiring is formed in contact with the second wiring 14 exposed at the bottom of the third opening 16 and in contact with the third insulating film 21 arranged along the opening end of the third opening 16 . The third wiring 23 is electrically connected to the emitter layer 5 at a short distance via a portion of the second wiring 14 , a portion of the first wiring 11 a , and the emitter electrode 6 located directly on the emitter l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com