Organic montmorillonite and application thereof

A technology of organic montmorillonite and montmorillonite, applied in the treatment of dyed low-molecular organic compounds, monocarboxylate copolymer adhesives, adhesive types, etc., can solve environmental pollution, corrosive smoke, Toxic and other problems, to achieve the effect of low cost, fast initial adhesion and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

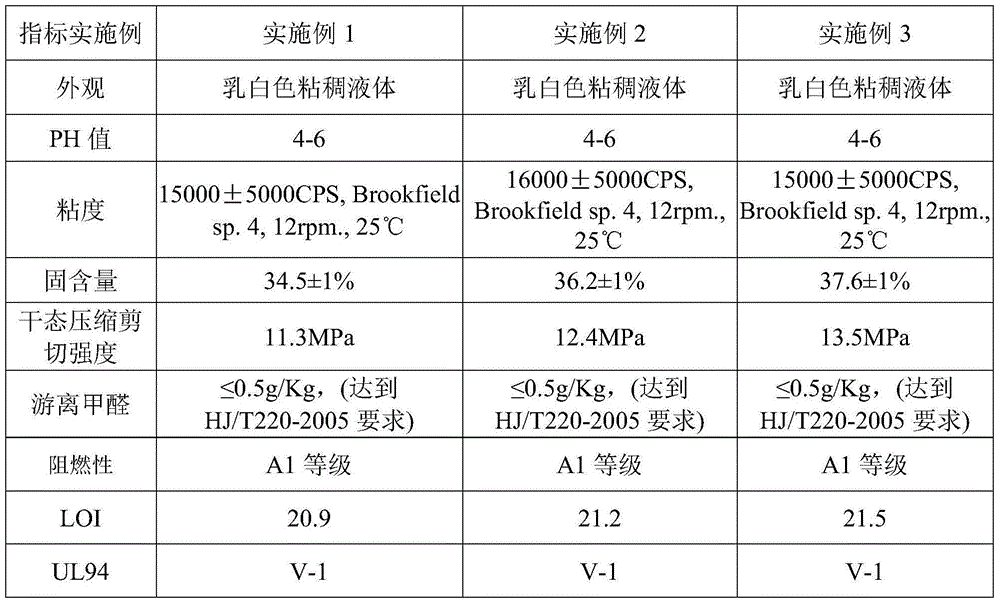

Examples

Embodiment 1

[0027] (1) Preparation of organic montmorillonite:

[0028] (1.1) Put 20 kg of natural montmorillonite in a device that has been added with 100 kg of water, stir for about 2.5 hours, let it stand for 5 hours, and then remove the lower layer of coarse sand larger than 200 mesh.

[0029] (1.2) Add 3 kilograms of sodium hexametaphosphate again, add 0.6 kilograms of concentration and be 33wt% hydrochloric acid solution, make the pH value of system be 5-6, after stirring, further divide and be greater than 400 order detritus minerals (feldspar, carbonate Wait);

[0030] (1.3) Repeat step 1.2 for 2 times to obtain the montmorillonite slurry or suspension, that is, the montmorillonite after purification and sodiumization;

[0031] (1.4) Organicization: Add 2.0 kg of cocamidopropyl betaine to the above-mentioned purified sodium montmorillonite solution while stirring, heat and stir in a water bath at 80°C for 2.0 hours, filter and dry, pass through 600 mesh after grinding Sieve, the...

Embodiment 2

[0037] (1) Preparation of organic montmorillonite:

[0038] (1.1) Put 25 kg of natural montmorillonite in a device that has added 110 kg of water, stir for about 2.8 hours, let stand for 5.5 hours, and then remove the lower layer of coarse sand greater than 200 mesh.

[0039] (1.2) Add 3.5 kilograms of sodium hexametaphosphate again, add 0.7 kilograms of concentration and be 33% hydrochloric acid solution, make the pH value of the system 5-6, after stirring, further divide and be greater than 400 order detritus minerals (feldspar, carbonate Wait);

[0040] (1.3) Repeat step 1.2 for 2 times to obtain the montmorillonite slurry or suspension, that is, the montmorillonite after purification and sodiumization;

[0041] (1.4) Organicization: Add 2.1 kg of octadecamidopropyl betaine to the above-mentioned purified sodium montmorillonite solution while stirring, heat and stir in a water bath at 81°C for 2.3 hours, filter and dry, and pass through 600°C after grinding. Mesh sieve, the...

Embodiment 3

[0047] (1) Preparation of organic montmorillonite:

[0048] (1.1) Put 30 kg of natural montmorillonite in a device that has been added with 120 kg of water, stir for about 3.0 hours, let stand for 6.0 hours, and then remove the lower layer of coarse sand greater than 200 mesh.

[0049] (1.2) Add 4 kilograms of sodium hexametaphosphate again, add 0.8 kilograms of concentration and be 33% hydrochloric acid solution, make the pH value of the system 5-6, after stirring, further divide and be greater than 400 mesh clastic minerals (feldspar, carbonate Wait);

[0050] (1.3) Repeat step 1.2 for 3 times to obtain the montmorillonite slurry or suspension, that is, the montmorillonite after purification and sodiumization;

[0051] (1.4) Organicization: Add 1 kg of octadecamidopropyl betaine and 1.2 kg of cocamidopropyl betaine to the above-mentioned purified sodium montmorillonite solution while stirring, heat and stir in a water bath at 82°C for 2.5 After one hour, filter and dry, pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com