Coconut-shell fiber-based activated carbon for supercapacitor and preparation method of activated carbon

A technology of supercapacitor and coir fiber, which is applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of not being able to have high specific surface area and high specific capacity at the same time, and achieve the effects of low cost, simple process and rich source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

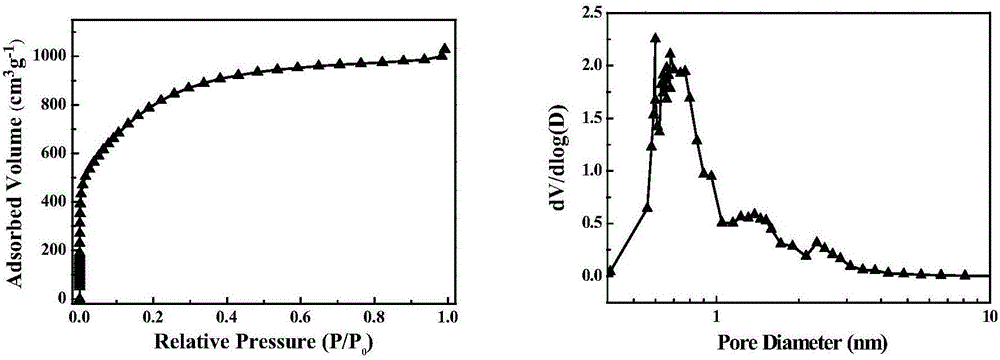

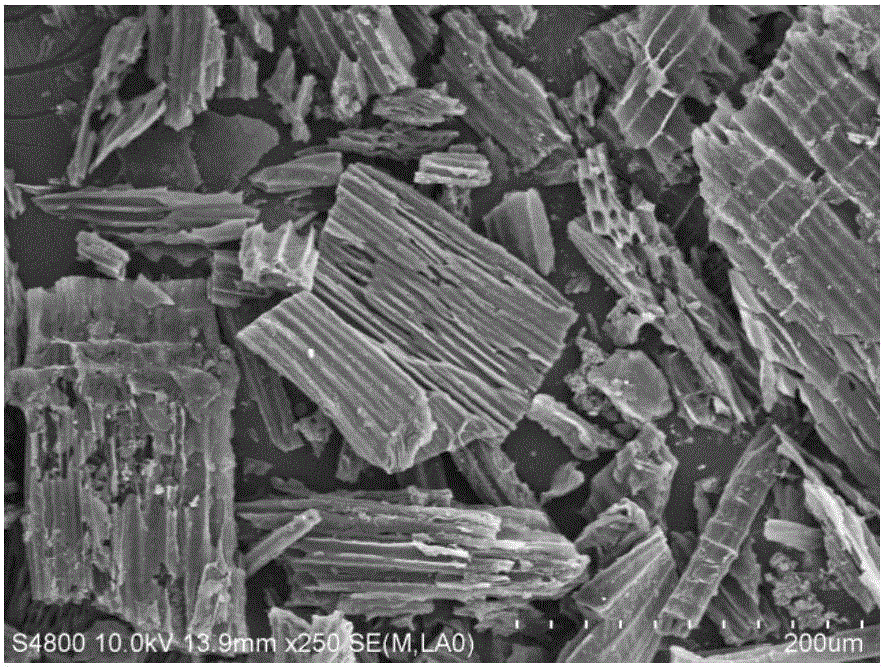

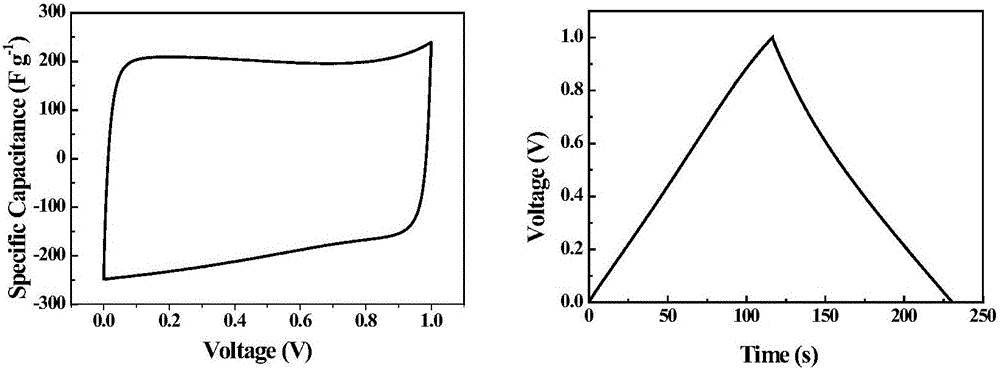

[0018] Embodiment 1: the preparation method of coconut shell fiber-based activated carbon for supercapacitor comprises the following steps:

[0019] (1) First, the coconut shell fiber is soaked in a 1% NaOH solution for 48 hours, washed with distilled water until neutral, and placed in an oven to dry at 110°C. After drying, pulverize, take 10g and put it in a closed furnace chamber, in an inert gas N 2 Under a protective atmosphere, the temperature was raised to 700°C at a rate of 3°C / min, and kept at 700°C for 1.5 hours to obtain a carbonized product;

[0020] (2) 2g of the carbonized product obtained in step (1) is ground and mixed with the 4g KOH activator; 2 ), the heating rate is 3°C / min, the temperature is raised to 800°C, and the activated product is obtained at 850°C for 1 hour;

[0021] (3) Wash the activated product obtained in step (2) with water, wash with 2% dilute hydrochloric acid, and then wash with water until the pH is 6-7; dry to prepare the coconut shell ...

Embodiment 2

[0022] Embodiment 2: the preparation method of coconut shell fiber-based activated carbon for supercapacitor comprises the following steps:

[0023] (1) First, soak the coconut shell fiber in NaOH solution with a mass fraction of 2% for 48 hours, wash it with distilled water until neutral, place it in an oven and dry it at 110°C, grind it after drying, take 10g and place it in a closed furnace In the cavity, under the protective atmosphere of inert gas, the temperature is raised to 700°C at a rate of 3°C / min, and the carbonization product is obtained at 700°C for 1.5h;

[0024] (2) 2g of the carbonized product obtained in step (1) is ground and mixed with 6gKOH activator; 2 Under a protective atmosphere, the heating rate is 3°C / min to 850°C, and the activated product is obtained at 850°C for 1 hour;

[0025] (3) Wash the activated product obtained in step (2) with water, wash with 2% dilute hydrochloric acid, and then wash with water until the pH is 6-7; dry to prepare the co...

Embodiment 3

[0026] Embodiment 3: the preparation method of coconut shell fiber-based activated carbon for supercapacitor comprises the following steps:

[0027] (1) First, soak the coconut shell fiber in a 3% NaOH solution for 48 hours, wash it with distilled water until it is neutral, place it in an oven and dry it at 110°C, grind it after drying, take 10g and place it in a closed furnace chamber, in an inert gas N 2 Under a protective atmosphere, heat up to 700°C at a rate of 3°C / min, and hold at 700°C for 1 hour to obtain a carbonized product;

[0028] (2) 2g of the carbonized product obtained in step (1) is ground and mixed with the 8gKOH activator; 2 ), the heating rate is 3°C / min, the temperature is raised to 850°C, and the activated product is obtained by keeping the temperature at 850°C for 1h;

[0029] (3) Wash the activated product obtained in step (2), remove impurities with 2% dilute hydrochloric acid, and then wash until the pH is 6-7; dry, and prepare coconut shell fiber-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com