Furniture reconsolidated bamboo preparation method

A technology for recombining bamboo and furniture, applied in the direction of household components, household appliances, other household appliances, etc., can solve the problems of difficult to reach the standard formaldehyde content, cracking or borers, rebound and other problems, so as to alleviate the shortage of wood resources, not easy to crack or deform, The effect of shortening the compression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

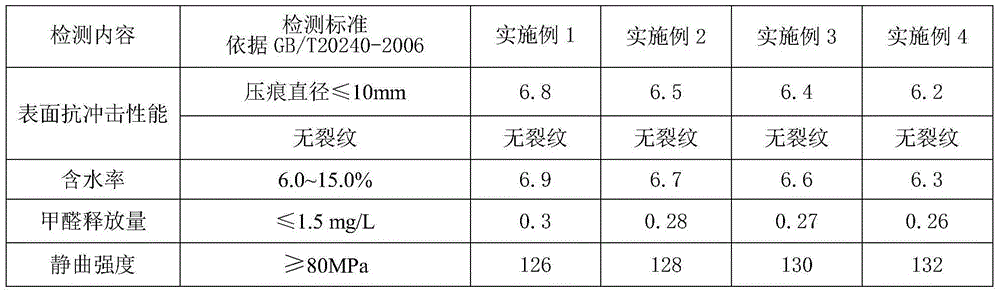

Examples

preparation example Construction

[0028] The preparation method of the present invention comprises the following steps:

[0029] 1) cut section: the moso bamboo is cut off to obtain a bamboo section with a length of 1.8-2.0 meters;

[0030] 2) sheet making: the bamboo section is longitudinally cut into several pieces, and the bamboo green on the surface of the bamboo section and the bamboo yellow on the inner layer are removed to obtain bamboo chips;

[0031] 3) Rolling: rolling the bamboo slices into interconnected loose mesh fibers;

[0032] 4) bundling: bundling the rolled multi-sheet loose mesh fiber filaments into small bundles to obtain bamboo bundles;

[0033] 5) Carbonization: Carry out carbonization treatment to the bamboo bundles, the carbonization temperature is 140-150°C, and the carbonization time is 1-2 hours;

[0034] 6) Cooling: cooling the carbonized bamboo bundles, that is, placing the bamboo bundles on the open space for natural cooling or placing them on a shelf for ventilation and coolin...

Embodiment 1

[0041] The preparation method of the present invention comprises the following steps:

[0042] 1) cut section: the moso bamboo is cut off to obtain a bamboo section with a length of 1.8 meters;

[0043] 2) sheet making: the bamboo section is longitudinally cut into several pieces, and the bamboo green on the surface of the bamboo section and the bamboo yellow on the inner layer are removed to obtain bamboo chips;

[0044] 3) Rolling: rolling the bamboo slices into interconnected loose mesh fibers;

[0045] 4) bundling: bundling the rolled multi-sheet loose mesh fiber filaments into small bundles to obtain bamboo bundles;

[0046] 5) carbonization: carry out carbonization treatment with bamboo bundle, carbonization temperature is 140 ℃, and carbonization time is 1 hour;

[0047] 6) Cooling: cooling the carbonized bamboo bundles, that is, placing the bamboo bundles on the open space for natural cooling, and the temperature of the cooled bamboo bundles is less than or equal to ...

Embodiment 2

[0054] The preparation method of the present invention comprises the following steps:

[0055] 1) cut section: the moso bamboo is cut off to obtain a bamboo section with a length of 1.9 meters;

[0056] 2) sheet making: the bamboo section is longitudinally cut into several pieces, and the bamboo green on the surface of the bamboo section and the bamboo yellow on the inner layer are removed to obtain bamboo chips;

[0057] 3) Rolling: rolling the bamboo slices into interconnected loose mesh fibers;

[0058] 4) bundling: bundling the rolled multi-sheet loose mesh fiber filaments into small bundles to obtain bamboo bundles;

[0059] 5) carbonization: carry out carbonization treatment with bamboo bundle, carbonization temperature is 145 ℃, and carbonization time is 1.5 hours;

[0060] 6) Cooling: cooling the carbonized bamboo bundles, that is, placing the bamboo bundles on a shelf for ventilation and cooling, and the temperature of the cooled bamboo bundles is less than or equal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com