Supported iron-based Fischer-Tropsch catalyst as well as preparation and application thereof

A catalyst, iron-based technology, applied in the field of preparation of the catalyst, can solve the problems of small production capacity and low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

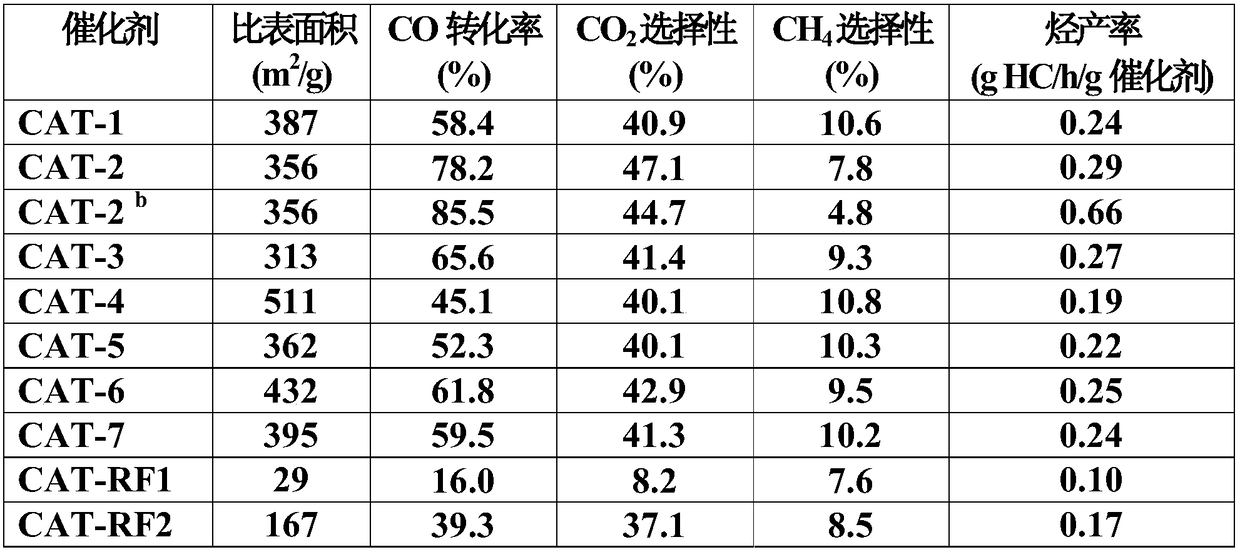

Examples

preparation example Construction

[0068] The carbon carrier preparation method of the present invention generally includes the steps of solution preparation, sol-gel reaction, ball formation, washing and drying, carbonization and inorganic template removal.

[0069]In step 1) as solution preparation step, phenols and formaldehyde selected from phenol and resorcinol are taken such that the phenol / aldehyde molar ratio is 1:1-1:3, preferably 1:1.5-1:2.5 , the phenols and formaldehyde jointly constitute an organic precursor. The polycondensate obtained by the combined polymerization of monomers of phenols selected from phenol and resorcinol and formaldehyde makes pelletization easy in subsequent steps. The organic precursor is then prepolymerized to form a sol solution, which facilitates spheroidization in subsequent steps.

[0070] In step 2) as a sol-gel reaction step, the organic precursor obtained in step 1) is dissolved in water selected from deionized water, pure water and ultrapure water, and then added to...

Embodiment 1

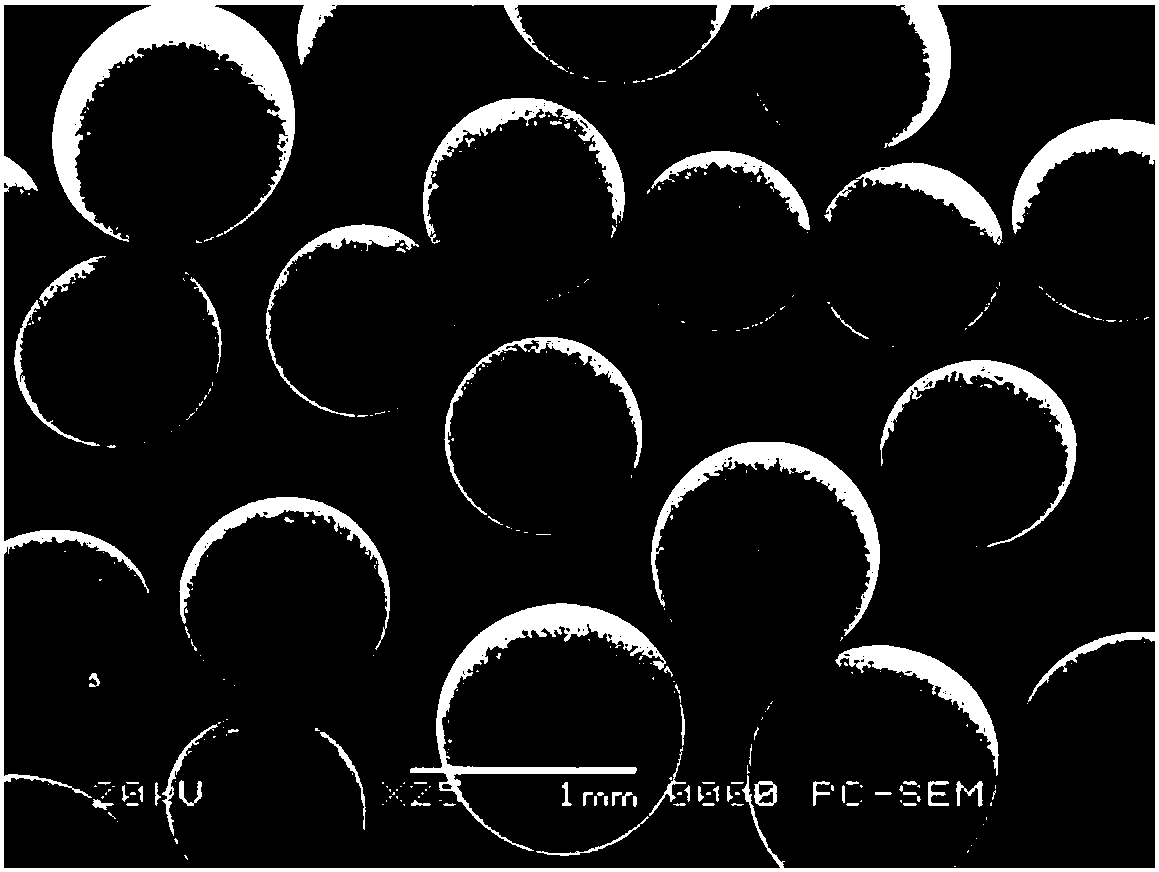

[0104] (1) Preparation of spherical mesoporous carbon supports

[0105] Dissolve 4.85 grams (0.044mol) of resorcinol and 7.16 grams of formalin (37% formaldehyde, formaldehyde is 0.088mol) in 15 grams of deionized water, add 0.05 grams of sodium carbonate as a catalyst, then add 25 grams of commercially available Hard templating agent silica nanoparticles LUDOX SM-30, and keep stirring. Add 5.49 grams of deionized water to ensure that the mass ratio of the total amount of the organic precursor and the inorganic template to the deionized water is 32.5 / 25. The obtained solution was placed in a water bath at 45° C., stirred and reacted for 45 minutes to obtain a sol solution. 270 g of liquid paraffin and 0.2 g of surfactant Span80 were placed in the reactor, the temperature was raised to 85° C., and the stirring rate in the reactor was controlled to be 200 rpm. The obtained sol solution was slowly poured into the reaction kettle, stirred for 0.5 h, and then aged in a water bath...

Embodiment 2

[0111] (1) Preparation of spherical mesoporous carbon supports

[0112] The preparation of the spherical mesoporous carbon support is exactly the same as the preparation of the spherical mesoporous carbon support in Example 1.

[0113] (2) Loading of active metal iron and additives

[0114] 1.25 g of ferric nitrate nonahydrate and 0.02 g of potassium carbonate were ultrasonically dissolved in 1 g of deionized water to obtain impregnation solution A. A ceramic evaporating dish containing 0.5 g of the above-prepared spherical mesoporous carbon was placed in an ultrasonicator, and the ultrasonic power was adjusted so that the spherical mesoporous carbon kept vibrating but could not fly out of the ceramic evaporating dish. Add the immersion solution A dropwise into the ceramic evaporating dish. During the dropping process of the impregnating liquid, the spherical mesoporous carbon was continuously stirred with a plastic key, so that the impregnating liquid was evenly dispersed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com