Continuous type preparation method of biomass activated carbon

A technology of activated carbon and biomass, used in chemical instruments and methods, carbon compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

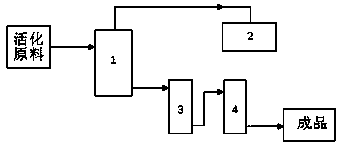

Method used

Image

Examples

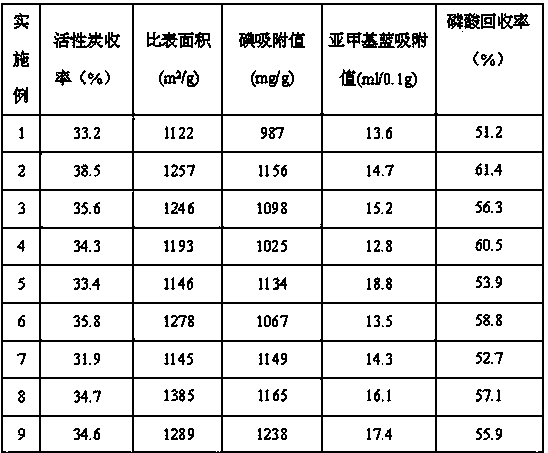

Embodiment 1

[0027] Crush the straw to 0.5mm, and under the action of 100W ultrasound, mix it with a phosphoric acid solution with a mass fraction of 15% according to the solid-liquid mass volume ratio (g / ml) 1:10, activate for 40min; start the screw before the microwave reactor 1 The feeder continuously transports the activated rice straw powder into the microwave reactor 1, and simultaneously turns on the microwave reactor 1 with a microwave power of 800W. Stay in device 1 for 3 minutes to obtain the crude activated carbon product. At the same time, the gas obtained from the reaction enters the gas absorber 2 containing absorbent tap water through the air duct to absorb phosphoric acid in the gas; after the crude activated carbon product in microwave reactor 1 is slightly cooled, Under the pushing action of the screw feeder, it enters the water vapor purging device 3, is purged and washed by water vapor for 20 minutes, and finally enters the condensation dryer 4 for drying to obtain the f...

Embodiment 2

[0029] Grind the corn stalks to 3 mm, and mix them evenly with the phosphoric acid solution with a mass fraction of 30% according to the solid-liquid mass volume ratio (g / ml) 1:12 under the action of 200W ultrasonic waves, and activate for 10 minutes; proceed according to the method described in Example 1. Material, microwave heating, steam purging and condensation drying: microwave power is 500W, to ensure that the activated corn stalk powder stays in the microwave reactor 1 for 10 minutes, and the crude activated carbon is obtained. Gas absorber 2, to absorb phosphoric acid in the gas; after the crude activated carbon is slightly cooled, it enters the water vapor purger 3, is purged and washed with water vapor for 15 minutes, and finally enters the condensing dryer 4 to dry to obtain the finished activated carbon; collect the gas absorber The absorption liquid in 2 and the water vapor at the bottom of the steam sweeper 3 purge the residual gas condensate, which is the recover...

Embodiment 3

[0031] Grind the wheat straw to 5mm, and under the action of 150W ultrasound, mix it evenly with the phosphoric acid solution with a mass fraction of 20% according to the solid-liquid mass volume ratio (g / ml) 1:5, activate for 20min; feed according to the method described in Example 1 , Microwave heating, steam purging and condensation drying: microwave power 600W, to ensure that the activated wheat straw powder stays in the microwave reactor 1 for 8 minutes to obtain the crude activated carbon. device 2 to absorb phosphoric acid in the gas; after the crude activated carbon is slightly cooled, it enters the water vapor purger 3, is purged and washed with water vapor for 20 minutes, and finally enters the condensing dryer 4 to dry to obtain the finished activated carbon; collect the gas in the absorber 2 The absorption liquid and the water vapor at the bottom of the steam sweeper 3 purge the residual gas condensate, which is the reclaimed phosphoric acid solution. The concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com