Reactive phosphorus triazine flame retardant for dyeing, and preparation method and application thereof

A reactive, triazine-based technology, applied in the field of flame retardants, can solve problems such as toxic gases, secondary hazards, and limited application range, and achieve the effects of good carbon formation, high thermal stability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

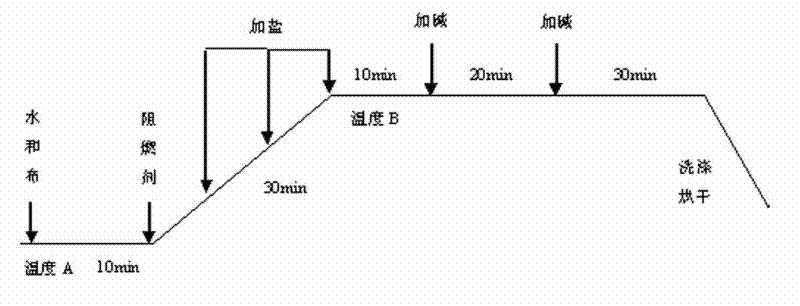

[0040] The preparation method of the reactive phosphorus-containing triazine flame retardant used in the dyeing process comprises the following steps:

[0041] (1) Synthesis of PEPA: Add 67.2g (0.50mol) of pentaerythritol and 200mL of 1,4-dioxane to a 500mL four-necked flask equipped with a nitrogen conduit, a thermometer, a constant pressure dropping funnel, a stirrer, and a reflux condenser Ring, start stirring, pass nitrogen protection, heat up to 80°C, add 76.6g (0.50mol) phosphorus oxychloride quickly and then slowly within 2h, after dropping, add 2~3 drops of triethylamine, and reflux for 10h , let it cool down to room temperature, and filtered to obtain a white solid, which was washed once with 100mL 1,4-dioxane, once with 100mL n-hexane, once with 100mL absolute ethanol, once with 50mL diethyl ether, and then placed in a vacuum at 60°C After drying in an oven for 5 hours, 83.7 g of a white solid was obtained, with a yield of 92.3%;

[0042] (2) In a 250mL four-necked ...

Embodiment 2

[0054] The preparation method of the reactive phosphorus-containing triazine flame retardant used in the dyeing process comprises the following steps:

[0055] (1) Synthesis of PEPA: Add 67.2g (0.50mol) of pentaerythritol and 200mL of 1,4-dioxane to a 500mL four-necked flask equipped with a nitrogen conduit, a thermometer, a constant pressure dropping funnel, a stirrer, and a reflux condenser ring, start stirring, pass nitrogen protection, heat up to 80°C, add 107.2g (0.70mol) phosphorus oxychloride quickly and then slowly within 2h, after dropping, add 2~3 drops of triethylamine, and reflux for 8h , let stand to cool to room temperature, filtered to obtain a white solid, washed four times with 100mL 1,4-dioxane, and then dried in a vacuum oven at 60°C for 5h to obtain a white solid with a yield of 91.6%;

[0056] (2) In a 250mL four-necked flask equipped with a condenser, a thermometer and a stirring device, add 0.025mol of cyanuric chloride powder, then add 30mL of dichlorom...

Embodiment 3

[0061] The preparation method of the reactive phosphorus-containing triazine flame retardant used in the dyeing process comprises the following steps:

[0062] (1) Synthesis of PEPA: Add 67.2g (0.50mol) of pentaerythritol and 200mL of 1,4-dioxane to a 500mL four-necked flask equipped with a nitrogen conduit, a thermometer, a constant pressure dropping funnel, a stirrer, and a reflux condenser ring, start stirring, pass nitrogen protection, heat up to 80°C, add 91.9g (0.60mol) phosphorus oxychloride quickly and then slowly within 2h, after dropping, add 2~3 drops of triethylamine, and reflux for 6h , stand to cool to room temperature, filter to obtain a white solid, wash once with 100mL of n-hexane, 100mL of absolute ethanol once, and 50mL of diethyl ether once, and then put it in a vacuum oven at 60°C for 5h to obtain a white solid. The yield is 89.9%;

[0063] (2) In a 250mL four-neck flask equipped with a condenser, a thermometer and a stirring device, add 0.025mol of cyanu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com