Building material prepared by synergistic carbonization of steel slag, desulfurized gypsum and fly ash and method

A technology for desulfurizing gypsum and fly ash is applied in the field of solid waste building materials, which can solve the problems of long carbonization curing time, low carbonization conversion rate of calcareous materials, and small carbon sequestration amount, so as to improve carbonization efficiency, promote carbonization, improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

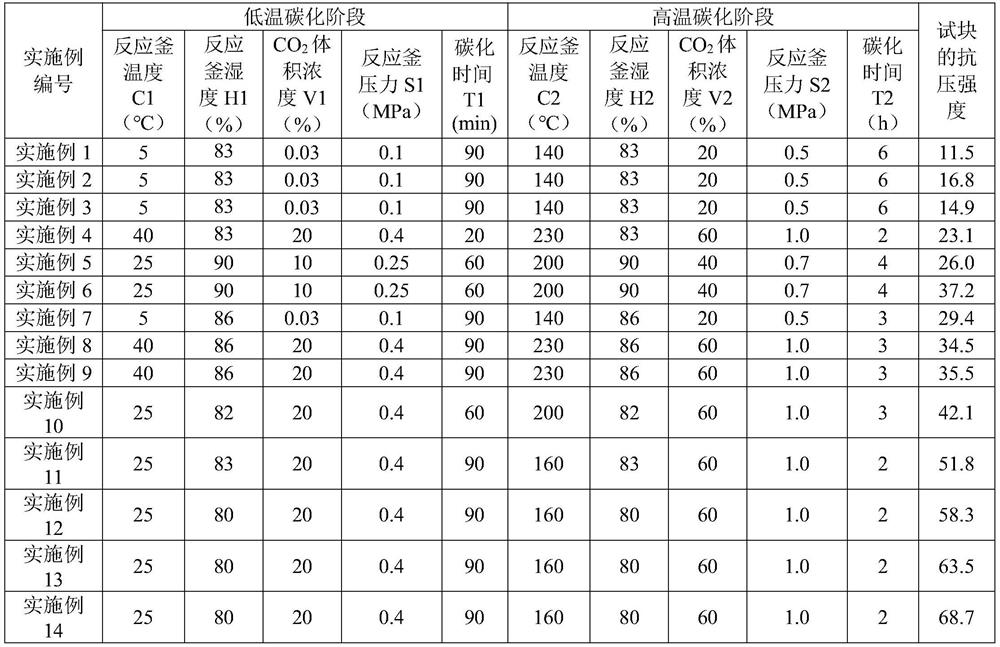

[0035] The present invention will be further described in detail below in conjunction with specific embodiments.

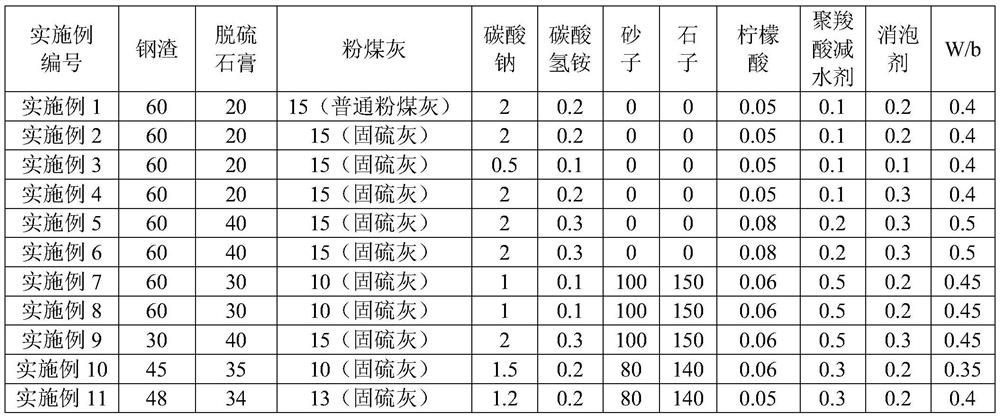

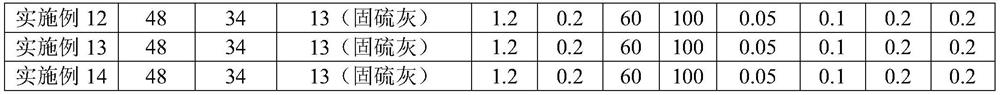

[0036] The building material prepared by synergistic carbonization of steel slag-desulfurized gypsum-fly ash is composed of the following raw materials in parts by weight: 30-60 parts of steel slag, 20-40 parts of desulfurized gypsum, 10-15 parts of fly ash, 0.5-2 parts of sodium carbonate, Ammonium bicarbonate 0.1-0.3 parts, fine aggregate 0-100 parts, coarse aggregate 0-150 parts, retarder 0.05-0.08 parts, water reducing agent 0.1-0.5 parts, defoamer 0.1-0.3 parts.

[0037] The fly ash is a mixture of one or more of ordinary fly ash, sulfur-fixed fly ash, and denitrification fly ash produced by a pulverized coal furnace, and the sulfur-fixed ash is produced by a circulating fluidized bed boiler. The sulfur-fixing ash; the particle size of the fine aggregate is 0.075mm to 4.75mm, including one or more of the crushed and screened fine aggregate of construction was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com