Active powder concrete applicable to road and bridge project

A technology of active powder and concrete, which is applied in the field of building materials, can solve the problems of low added value of products and low overall utilization rate, and achieve the effect of solving the problem of high added value utilization, enriching types, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

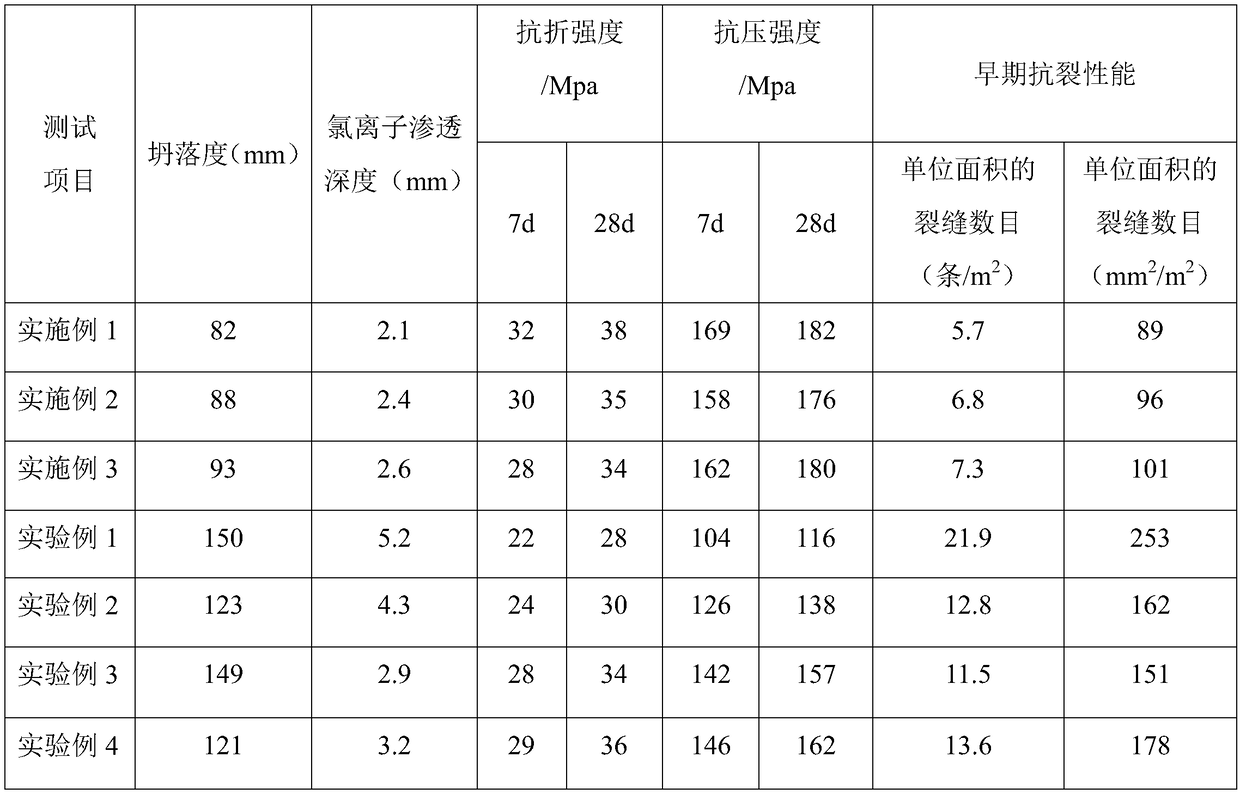

Examples

preparation example Construction

[0050] The active powder concrete material prepared by the present invention can effectively adjust the hardening time by rationally deploying various proportioning materials, and reduce the occurrence of cracking caused by too fast hardening of the concrete; at the same time, by controlling the heat of hydration, the internal temperature of the concrete rises The speed slows down, which slows down the temperature cracks caused by the large temperature difference between the inside and outside of the reactive powder concrete; at the same time, it significantly improves the internal fluidity of the concrete, making the internal density of the reactive powder concrete more uniform, and improving the crack resistance while ensuring the mechanical strength of the concrete. performance.

[0051] In yet another specific embodiment of the present invention, the preparation method of above-mentioned active powder concrete material is provided, and described preparation method comprises...

Embodiment 1

[0065] A reactive powder concrete material made of the following components by weight:

[0066] 70 parts of cement, 40 parts of quartz sand, 13 parts of silica fume, 10 parts of steel fiber, 1.5 parts of polycarboxylate superplasticizer, 2 parts of expansion agent, 5 parts of steel slag powder, 1 part of triethanolamine, 19 parts of water, retarder 0.9 servings.

[0067] Wherein, cement is P·O4 2.5 cement;

[0068] The particle size range of the quartz sand is controlled between 0.6-1.0mm, wherein the mass ratio of the 0.6-0.8mm-sized quartz sand to the 0.8-1.0mm-sized quartz sand is 1:2.5;

[0069] The silica fume is a by-product of ferrosilicon smelting or industrial silicon production, with an average particle size of 0.1-0.2 μm and a specific surface area of 15-25 m 2 / g;

[0070] The diameter of the steel fiber is 0.18-0.25mm, and the length is 10-15mm;

[0071] The polycarboxylic acid superplasticizer has a water reducing rate higher than 30%;

[0072] The expansi...

Embodiment 2

[0080] A reactive powder concrete material made of the following components by weight:

[0081] 65 parts of cement, 45 parts of quartz sand, 12 parts of silica fume, 10 parts of steel fiber, 2 parts of polycarboxylate superplasticizer, 2 parts of expansion agent, 4 parts of steel slag powder, 1 part of triethanolamine, 20 parts of water, retarder 1.2 servings.

[0082] Wherein, cement is P·O4 2.5 cement;

[0083] The particle size range of the quartz sand is controlled between 0.6-1.0mm, wherein the mass ratio of the 0.6-0.8mm-sized quartz sand to the 0.8-1.0mm-sized quartz sand is 1:2;

[0084] The silica fume is a by-product of ferrosilicon smelting or industrial silicon production, with an average particle size of 0.1-0.2 μm and a specific surface area of 15-25 m 2 / g;

[0085] The diameter of the steel fiber is 0.18-0.25mm, and the length is 10-15mm;

[0086] The polycarboxylic acid superplasticizer has a water reducing rate higher than 30%;

[0087] The expansion a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com