Gypsum-based heat insulation board and production method thereof

A thermal insulation board and gypsum-based technology, applied in the field of building materials, can solve problems such as lack of breathing function, long maintenance period of finished products, complicated manufacturing process, etc., and achieve the effect of good thermal insulation performance, low density and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

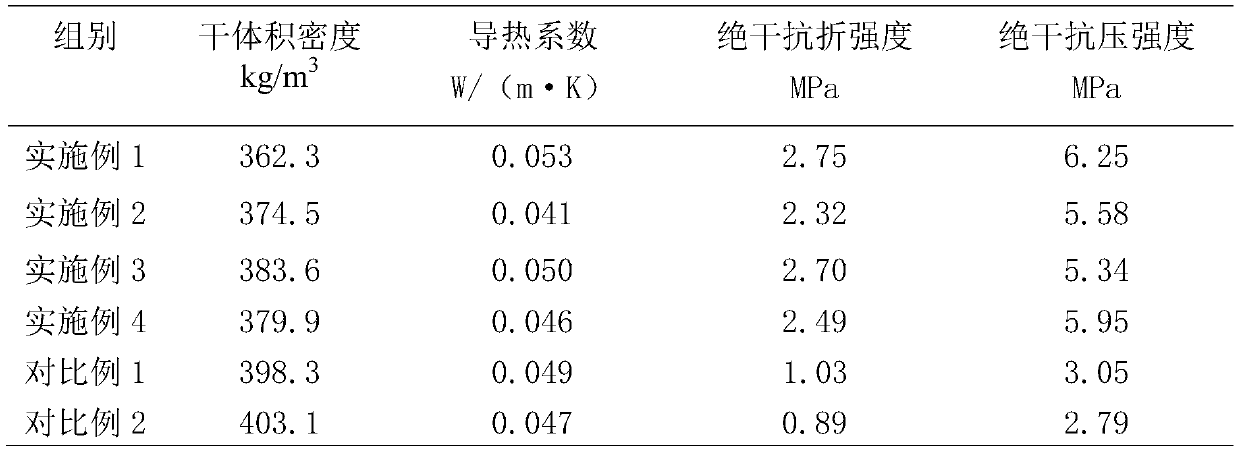

Examples

Embodiment 1

[0020] A kind of preparation method of gypsum-based insulation board, concrete steps are:

[0021] 1) Dry powder ingredients: 100 parts of hemihydrate gypsum, 30 parts of anhydrous gypsum, 0.05 parts of polycarboxylate superplasticizer, 0.1 part of polyethylene oxide, 0.08 parts of protein retarder for gypsum, and 0.05 parts of cellulose ether, Send to dry powder mixer, mix evenly;

[0022] 2) Preparation of foaming liquid: 5 parts of foaming agent (50% alkyl polyglycoside, 30% sodium alkylbenzene sulfonate, 20% cocamidopropyl betaine), 0.5 part of polyacrylamide, 160 parts of water Parts are mixed evenly to obtain a foaming solution, which is placed in a foaming machine for foaming to form foam, and the foaming time is 3 minutes;

[0023] 3) Slurry ingredients: add 60 parts of water to the mixed dry powder and stir to obtain a mixed slurry;

[0024] 4) uniformly mixing the mixed slurry with the foam to obtain a porous structure slurry, and molded and demoulded to form a cor...

Embodiment 2

[0027] A kind of preparation method of gypsum-based insulation board, concrete steps are:

[0028] 1) Dry powder ingredients: put 100 parts of hemihydrate gypsum, 0.05 parts of polycarboxylate superplasticizer, 0.1 part of acrylamide, 0.15 parts of sodium hexametaphosphate, and 0.05 parts of starch ether into a dry powder mixer and mix well;

[0029] 2) Preparation of foaming liquid: 5 parts of foaming agent (45% alkyl polyglycoside, 40% sodium alkylbenzene sulfonate, 15% cocamidopropyl betaine), 0.5 part of polyacrylamide, 160 parts of water Parts were mixed evenly to obtain a foaming solution, which was placed in a foaming machine for foaming to form foam, and the foaming time was 4 minutes;

[0030] 3) Slurry ingredients: add 80 parts of water to the mixed dry powder and stir to obtain a mixed slurry;

[0031] 4) uniformly mixing the mixed slurry with the foam to obtain a porous structure slurry, and molded and demoulded to form a core board;

[0032] 5) Pour the slurry o...

Embodiment 3

[0034] A kind of preparation method of gypsum-based insulation board, concrete steps are:

[0035] 1) Dry powder ingredients: mix 100 parts of hemihydrate gypsum, 50 parts of anhydrous gypsum, 0.05 parts of polycarboxylate superplasticizer, 0.1 part of polyethylene oxide, 0.05 parts of protein retarder for gypsum, and 0.06 parts of starch ether. Put into dry powder mixer, mix well;

[0036] 2) Preparation of foaming liquid: 10 parts of foaming agent (50% alkyl polyglycoside, 30% sodium alkylbenzene sulfonate, 20% cocamidopropyl betaine), 1 part of silicone amide, 350 parts of water Parts are mixed evenly to obtain a foaming solution, which is placed in a foaming machine for foaming to form foam, and the foaming time is 3 minutes;

[0037] 3) Slurry ingredients: add 100 parts of water to the mixed dry powder and stir to obtain a mixed slurry;

[0038] 4) uniformly mixing the mixed slurry with the foam to obtain a porous structure slurry, and molded and demoulded to form a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com