Fireproof floor and preparation method thereof

A floor and Baume-degree technology, applied in the direction of architecture, building structure, floor, etc., can solve the problems of no windproof, shockproof ability, low safety, low cost, etc., to achieve outstanding fire performance, convenient operation, and product quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

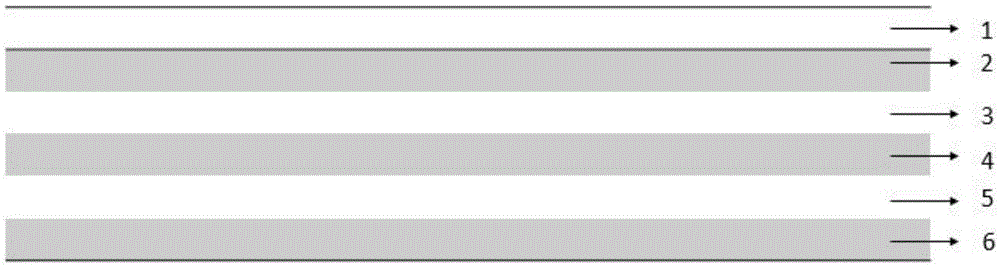

[0028] Prepare the fireproof floor according to the accompanying drawings in the instruction manual. From top to bottom, there are surface paste layer, non-woven fabric layer, glass fiber cloth layer, filler layer, glass fiber cloth layer, and non-woven fabric layer. The preparation method is as follows:

[0029] (1) Add the slurry of the batter layer to the formwork, and simultaneously extrude it with 6×6 glass fiber cloth and 10g non-woven fabric to determine the thickness to synthesize the batter layer; the raw material composition of the batter layer is: iron oxide yellow 2kg Magnesium oxide 50kg; Magnesium chloride solution (28 degrees Baume) 40kg; Talcum powder 20kg.

[0030] (2) Add two layers of 5×5 glass fiber cloth to the batter layer after setting the thickness;

[0031] (3) Put the slurry of the filler layer on the surface layer and the second layer of glass fiber cloth. The raw materials of the filler layer are composed of: magnesia 100kg; magnesium sulfate soluti...

Embodiment 2

[0038] Prepare the fireproof floor according to the accompanying drawings in the instruction manual. From top to bottom, there are surface paste layer, non-woven fabric layer, glass fiber cloth layer, filler layer, glass fiber cloth layer, and non-woven fabric layer. The preparation method is as follows:

[0039] (1) Add the slurry of the batter layer to the formwork, and simultaneously extrude it with 6×6 glass fiber cloth and 12g non-woven fabric to determine the thickness to synthesize the batter layer; the raw material composition of the batter layer is: iron oxide red 2kg Magnesium oxide 50kg; Magnesium sulfate solution (28 degrees Baume) 40kg; Talcum powder 20kg.

[0040] (2) Add two layers of 6×6 glass fiber cloth to the batter layer after setting the thickness,

[0041] (3) Put the slurry of the filler layer on the surface layer and the second layer of glass fiber cloth. The raw materials of the filler layer are composed of: magnesia 140kg; magnesium chloride solution ...

Embodiment 3

[0045] Prepare the fireproof floor according to the accompanying drawings in the instruction manual. From top to bottom, there are surface paste layer, non-woven fabric layer, glass fiber cloth layer, filler layer, glass fiber cloth layer, and non-woven fabric layer. The preparation method is as follows:

[0046] (1) Add the slurry of the batter layer to the formwork, and simultaneously extrude it with 6×4 glass fiber cloth and 16g non-woven fabric to determine the thickness to synthesize the batter layer; the raw material composition of the batter layer is: iron oxide blue 2kg Magnesium oxide 50kg; Magnesium chloride solution (28 degrees Baume) 40kg; Talcum powder 20kg.

[0047] (2) Add two layers of 6×4 glass fiber cloth to the batter layer after setting the thickness,

[0048] (3) Put the slurry of the filler layer on the surface layer and the second layer of glass fiber cloth. The raw materials of the filler layer are composed of: 120kg of magnesium oxide; 150kg of magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com