Double-component polymer-cement-base waterproof mortar and preparation method thereof

A waterproof mortar and polymer technology, applied in the field of mortar, can solve the problems of poor anti-aging ability, environmental and human hazards, poor impermeability of rigid waterproof mortar, etc., and achieve the effect of excellent flexural resistance and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the two-component polymer cement-based waterproof mortar is as follows:

[0039] (1), respectively weigh the raw materials in the liquid material component and the raw materials in the powder material component according to the above-mentioned parts by weight, mix the raw materials in the liquid material component and the raw materials in the powder material component respectively to make a liquid Material components and powder components;

[0040] (2) Mix and stir the liquid material component and the powder material component at a ratio of 1:3.0-4.0.

[0041] The physical performance indicators of the two-component polymer cement-based waterproof mortar formed after mixing and stirring are as follows:

[0042]

[0043] Note: According to JC / T 984-2011 (Type II) standard

Embodiment 1

[0045] Configure the liquid material components,

[0046] Liquid material component comprises the raw material of following weight portion:

[0047]

[0048] Mix the above ingredients;

[0049] Configure the powder components,

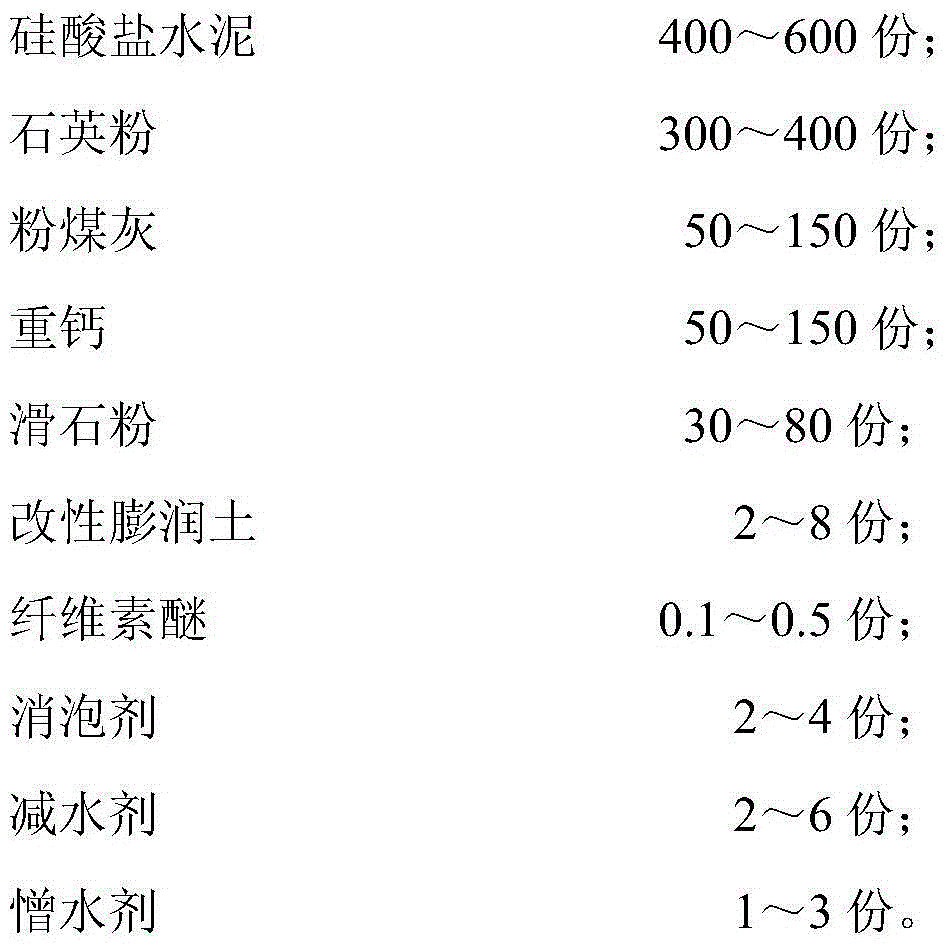

[0050] Powder component comprises the raw material of following weight portion:

[0051]

[0052] Mix and grind the above ingredients;

[0053] Mix the prepared liquid material and powder material according to the weight ratio of 1:3.5, mix and stir on a mixer with a speed of 300 rpm for 10 to 15 minutes before use.

[0054] The performance data of the product that this embodiment obtains:

[0055]

[0056]

Embodiment 2

[0058] Configure the liquid material components,

[0059] Liquid material component comprises the raw material of following weight portion:

[0060]

[0061] Mix the above ingredients;

[0062] Configure the powder components,

[0063] Powder component comprises the raw material of following weight portion:

[0064]

[0065]

[0066] Mix and grind the above ingredients;

[0067] Mix the prepared liquid material and powder material according to the weight ratio of 1:3.7, mix and stir on a mixer with a speed of 300 rpm for 10 to 15 minutes before use.

[0068] The performance data of the product that this embodiment obtains:

[0069]

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com