Dual-phase steel tube for low-temperature pressure vessel and preparation method of dual-phase steel tube

A pressure vessel, dual-phase steel technology, applied in the field of pressure vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to the second aspect of the present invention, the present invention provides a method for preparing the dual-phase steel pipe for low-temperature pressure vessels, the method comprising the following steps:

[0036] 1) Steel refining: smelting raw materials;

[0037] 2) Steel pipe forming: the pipe blank is manufactured by continuous casting or die casting, and then formed by rolling;

[0038] 3) Heat treatment: The delivery state of the formed steel pipe is solid solution.

[0039] Among them, the concept of solid solution is well known to those skilled in the art, specifically, solid solution is to heat steel and alloy to the temperature of single-phase solid solution and through sufficient heat preservation, so that certain components in steel and alloy dissolve into the matrix In the tissue, and form a uniform solid solution, and then rapidly cooled, so that the dissolved composition is preserved in the solid solution, this heat treatment is called solid...

Embodiment 1

[0047] This embodiment is used to illustrate the dual-phase steel pipe for low-temperature pressure vessel and its preparation method of the present invention.

[0048] 1) Steel refining: the raw materials are initially smelted in an electric arc furnace, and then refined outside the LF furnace;

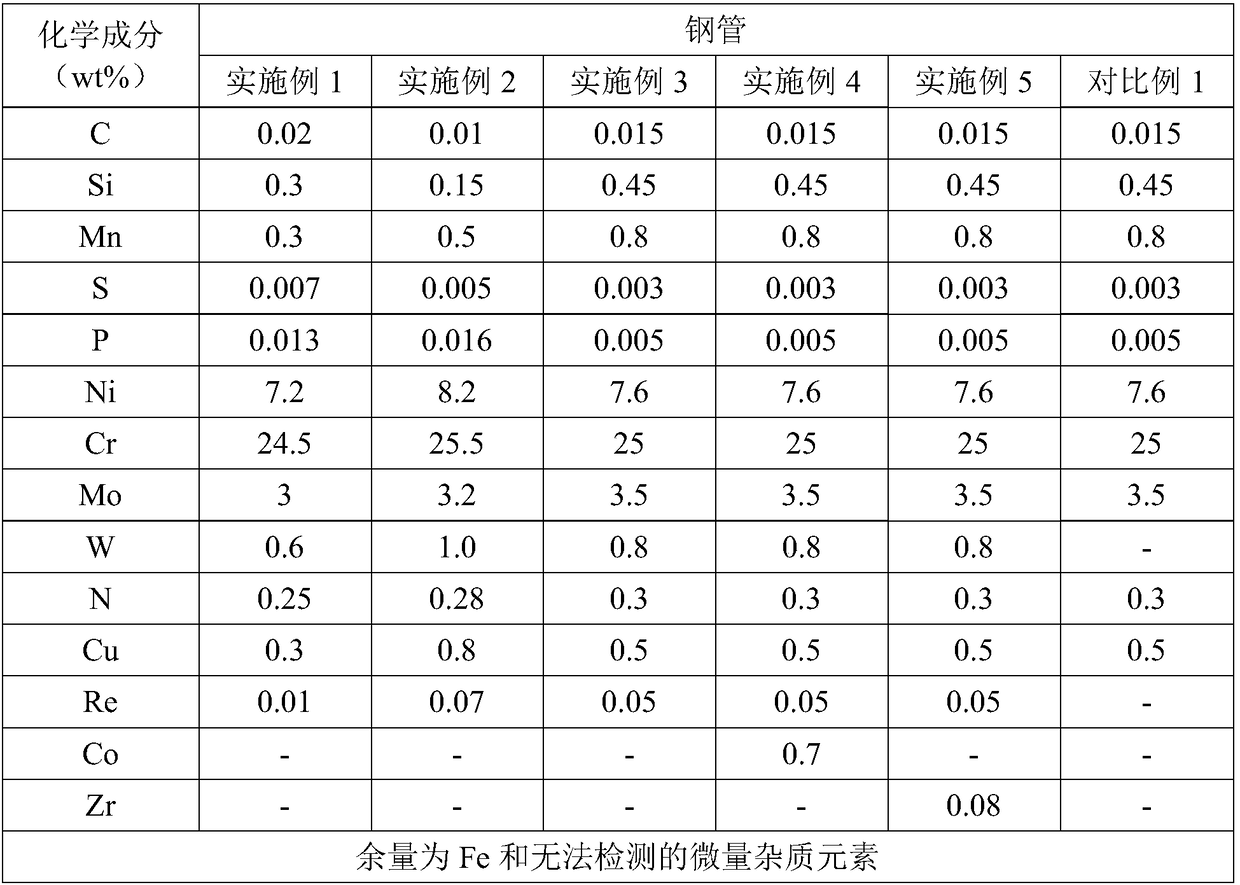

[0049] 2) Steel pipe forming: the pipe blank is manufactured by continuous casting process, and then formed by hot rolling method to obtain a steel pipe with a specification of Φ325×15. The chemical composition of the steel pipe is shown in Table 1;

[0050] 3) Heat treatment: The delivery state of the formed steel pipe is solid solution, the solid solution temperature is 1075°C, and the cooling is accelerated by air cooling at a rate of 10°C / s.

Embodiment 2

[0052] This embodiment is used to illustrate the dual-phase steel pipe for low-temperature pressure vessel and its preparation method of the present invention.

[0053] The implementation mode is the same as that in Example 1, wherein the chemical composition of the prepared steel pipe is shown in Table 1, the solid solution temperature is 1105°C, and the cooling rate is 5°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com