Polyformaldehyde fiber improved geopolymer recycled concrete

A technology of recycled concrete and polyoxymethylene fibers, which is applied in cement production and other directions, can solve the problems of inability to distribute uniformly, reduce strength and toughness, and be expensive, achieve high practical value and promotion value, improve long-term stability, and excellent alkali resistance. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

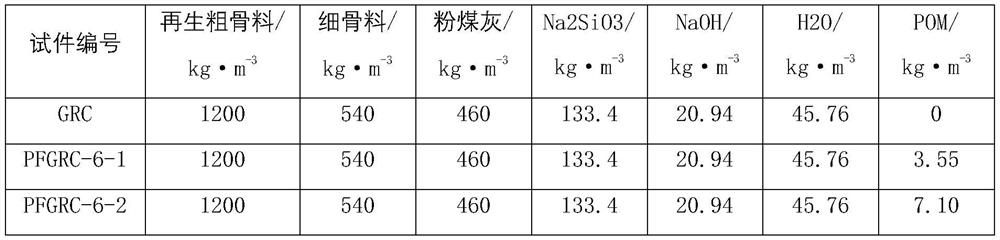

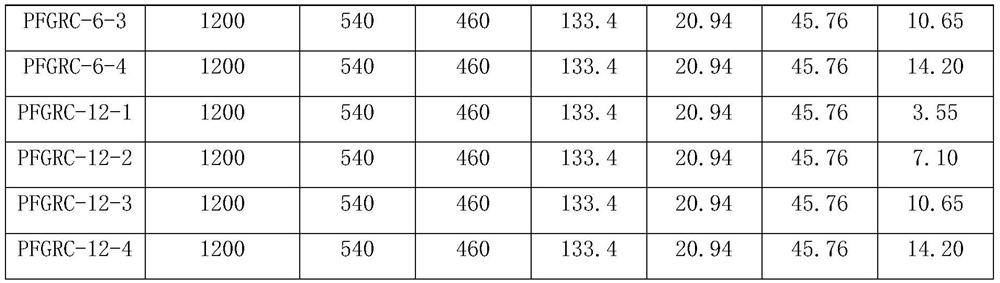

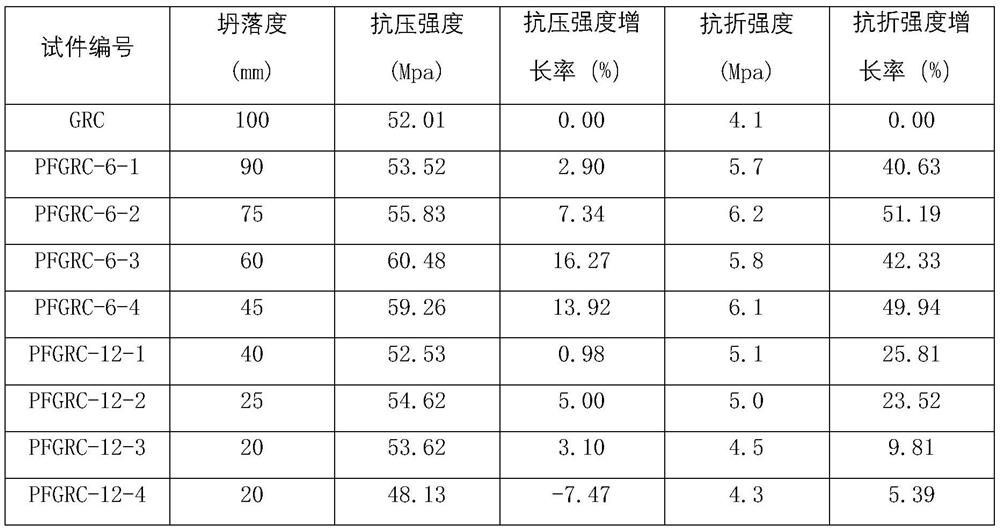

[0013] This embodiment proposes a polyoxymethylene fiber with flexural strength to improve geopolymer recycled concrete and its improvement method. Common synthetic fibers include polypropylene fiber, polyacrylonitrile fiber, polyvinyl alcohol fiber, polyoxymethylene (POM) fiber etc. In this embodiment, considering the addition of polyoxymethylene fiber to the recycled concrete of geopolymer to prepare polyoxymethylene fiber geopolymer recycled concrete, this embodiment selects polyoxymethylene fibers with a length of 6 mm and 12 mm, and studies that the volume content of polyoxymethylene fibers is 0 respectively. %, 0.25%, 0.5%, 0.75%, and 1% of the mechanical properties of geopolymer recycled concrete, and their formula ratios are shown in the table below:

[0014]

[0015]

[0016] In the present embodiment, the polyoxymethylene fiber physical performance parameters are as follows:

[0017] Fiber type Length (mm) Diameter (μm) Density (g / cm 3 )

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com