PVDF polymer separation membrane and preparation method thereof

A polymer and separation membrane technology, which is applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of PVDF membrane material yellowing, decline in alkali corrosion resistance, aging, etc., and achieve excellent alkali resistance, Long service life and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

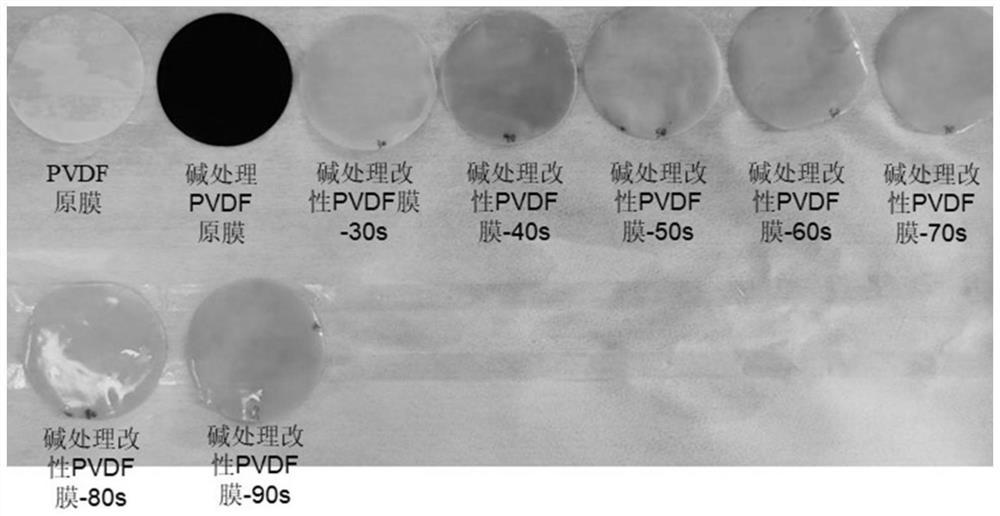

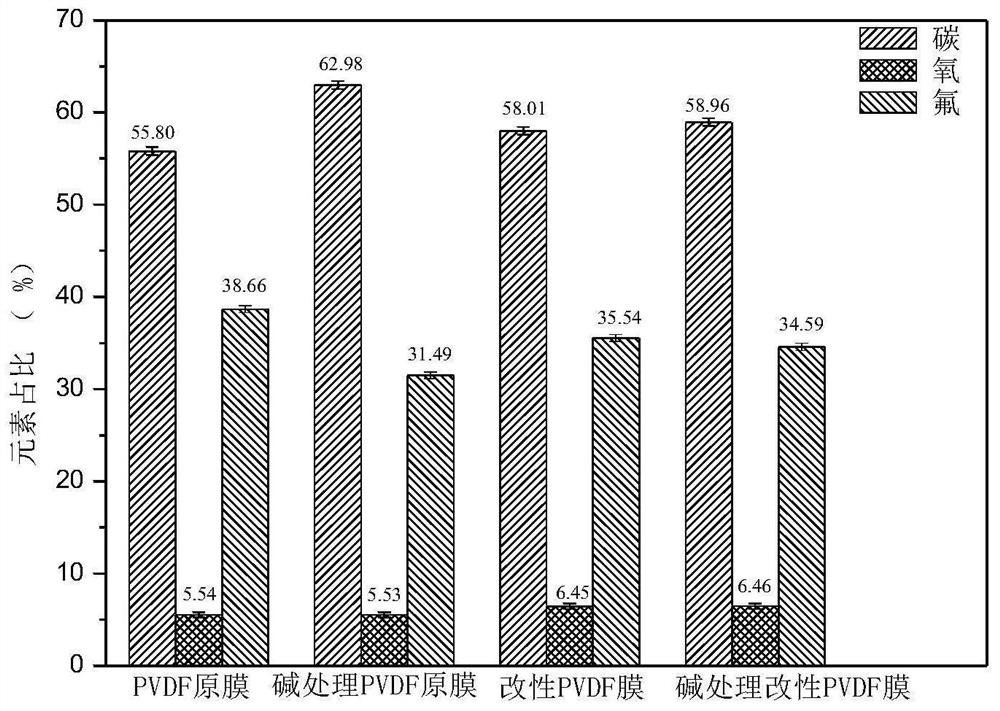

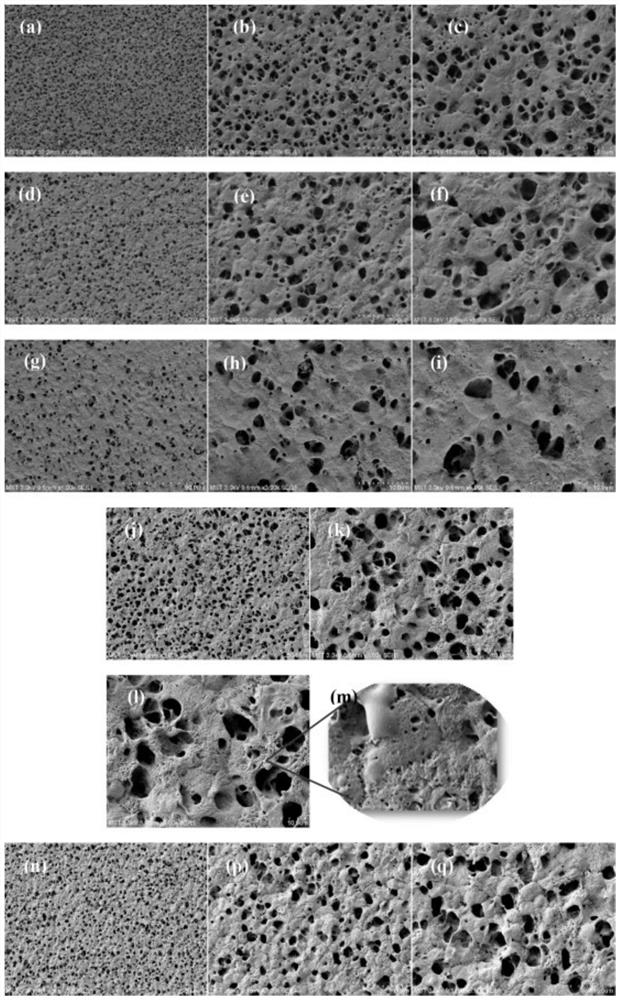

[0047] The preparation method of PDVF polymer separation membrane comprises the following steps:

[0048] (1)PVDF / nano-SiO2 2 Preparation of blend membranes

[0049] Dissolve 15 g of PVDF6010 in 60 g of DMAc, and then mix 2 g of SiO 2 Uniformly dispersed in DMAc. The porogen 2 g of PVPK30 was then added to the solution and kept stirring for 12 hours. After stirring, the solution was kept at 60° C. for 24 hours to defoam the casting solution. Then pour the casting solution on a clean glass plate, and use a scraper to coat the film (adjust the height of the scraper to 250 μm, and adjust the speed to 1.2m min -1 ). The glass plate was then immersed in a coagulation bath containing 15% DMAc aqueous solution (volume fraction) at 60°C. After the coagulation process was complete, the membrane was transferred to a 4% sodium hypochlorite solution and kept overnight.

[0050] (2) Infiltration pre-modification of the membrane surface

[0051] Dissolve 5 g of gelatin, 10 g of sodi...

Embodiment 1

[0105] Weigh 15 grams of PVDF6010 powder, 2 grams of PVPK30 powder, 2 grams of hydrophilic nano-silicon dioxide, and 60 grams of DMAC, stir at 60 degrees Celsius for 24 hours to form a homogeneous casting solution, and let stand for 24 hours for defoaming. Inducing phase separation to form a film; Weigh 5 grams of gelatin, 10 grams of sodium lauryl sulfate and 10 milliliters of glycerin to prepare a 10% aqueous solution of sodium lauryl sulfate 1 ; Weigh 0.1 gram of 1-hydroxycyclohexyl phenyl ketone (184), and 1.5 grams of polyester acrylic resin are dissolved in 17.15 grams of tripropylene glycol diacrylate (TPGDA) to prepare 8% polyester acrylate resin solution 2 ; soak the above membrane in the above solution ① and vibrate ultrasonically for three minutes, take out and remove excess alkyl anion compound droplets on the surface of the membrane, and then dry it naturally. Then put it in the resin solution for 24 hours, wait until the resin solution completely infiltrates the ...

Embodiment example 2

[0107] Weigh 15 grams of PVDF6010 powder, 2 grams of PVPK30 powder, 2 grams of hydrophilic nano-silicon dioxide, and 60 grams of DMAC, stir at 60 degrees Celsius for 24 hours to form a homogeneous casting solution, and let stand for 24 hours for defoaming. Inducing phase separation to form a film; Weigh 5 grams of gelatin, 10 grams of sodium lauryl sulfate and 10 milliliters of glycerin to prepare a 10% aqueous solution of sodium lauryl sulfate 1 ; Weigh 0.1 gram of 1-hydroxycyclohexyl phenyl ketone (184), 1.5 grams of polyester acrylic resin dissolved in 17.15 grams of diacrylate-1,6-hexanediol (HDDA) to prepare 8% polyester acrylic resin in solution 2 ; soak the above membrane in the above solution ① and vibrate ultrasonically for three minutes, take out and remove the excess alkyl anion compound droplets on the surface of the membrane, and then dry it naturally. Then place it in the resin solution for 24 hours, wait until the resin solution completely infiltrates the PVDF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com