Process for producing building plastic formwork by co-extrusion method and compound mould

A technology of plastic formwork and composite mould, applied in the field of co-extrusion production of building plastic formwork process and composite mould, can solve the problems of poor surface strength and easy to be corroded, so as to improve surface strength, strong alkali corrosion resistance and service life prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

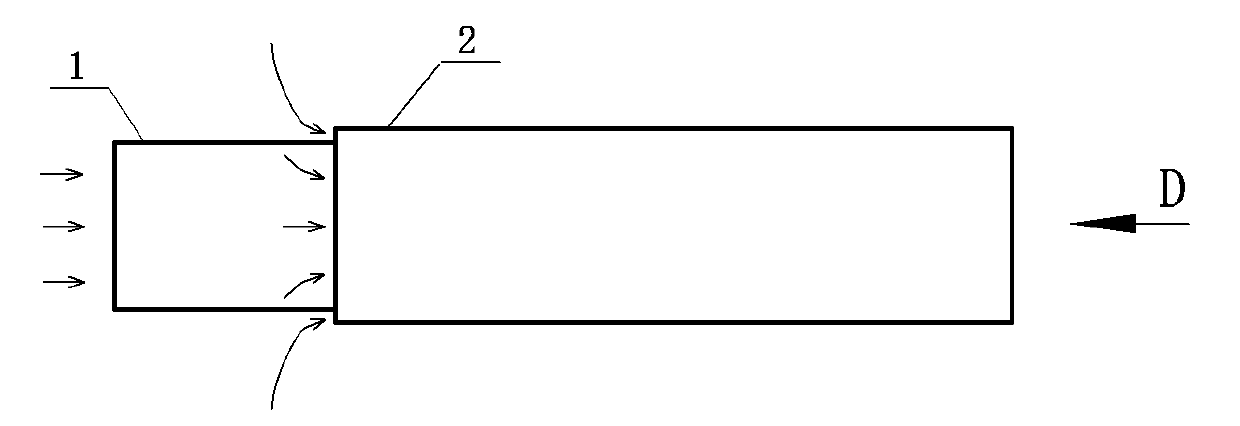

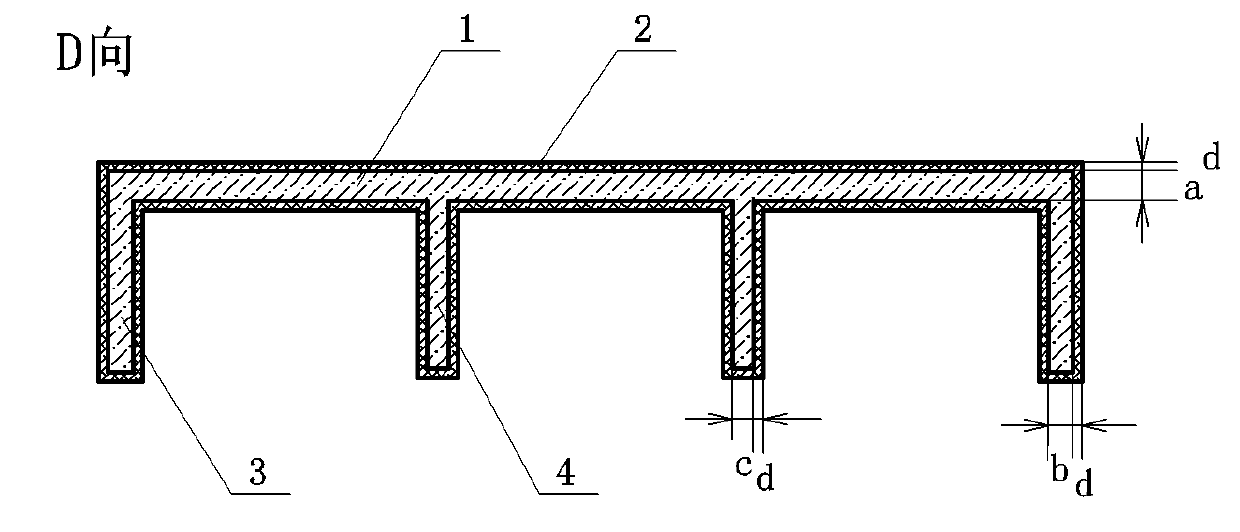

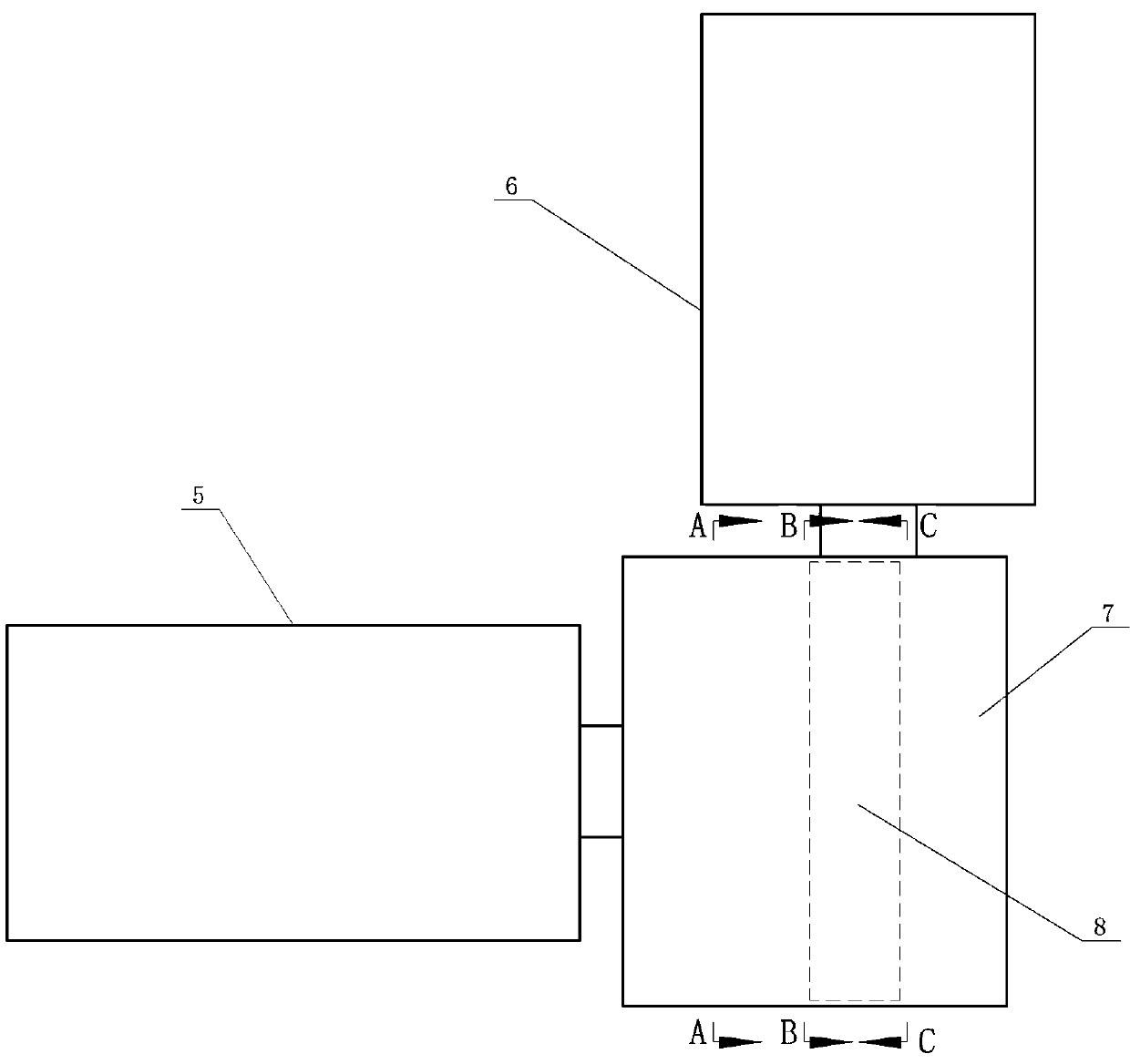

[0021] Embodiment 1: see figure 1 , figure 2 and image 3 , the co-extrusion method to produce architectural plastic templates uses two sets of plastic kneaders at the same time, which are the surface layer kneader and the inner core layer kneader. Plastic extruders are combined to form two plastic extruder production lines, and the two plastic extruder production lines simultaneously pass through composite molds to form composite plastic building templates, and then sequentially pass through vacuum setting machines, tractors and cutting machines to form multi-layer composite plastic buildings template product. Wherein, the surface layer plastic extruder 6 and the inner layer foam plastic extruder 5 are connected with the composite mold in a mutually perpendicular manner, see Figure 4 .

[0022] From Figure 5 , Figure 6 and Figure 7 It can be seen that the composite mold 7 includes the inner core layer forming channel 9 and the composite layer forming channel 10 i...

Embodiment 2

[0024] Embodiment 2: The content is basically the same as in Example 1, the difference is that an inner layer foamed plastic extruder and two surface layer plastic extruders are used, each extruder is connected with a composite mold respectively, and the two surface layers The plastic extruders are installed sequentially, and two sets of the same co-extrusion method as in Example 1 are adopted, that is, the co-extrusion method and structure described in Example 1 are adopted between the first surface plastic extruder and the inner layer, The first layer of composite template is formed, and the second surface layer plastic extruder and the first composite template that have been formed adopt the co-extrusion method and structure as described in Example 1 to form a composite template with an inner and outer three-layer structure.

Embodiment 3

[0025] Embodiment 3: see Figure 3 ~ Figure 7 , the composite mold includes a shell, the front end of the shell is provided with a mold hole inlet, the front end of the shell is provided with a mold hole outlet, and the middle shell side between the mold hole entrance and the mold outlet is provided with a surface layer plastic feeding port, The inlet of the mold hole is connected with the outlet of the inner layer plastic extruder, the inlet of the surface layer plastic is connected with the surface layer plastic extruder, and an electric heating device is arranged on the upper part or the side wall of the shell; corresponding to the surface layer plastic inlet A co-extrusion mold is installed in the inner cavity of the shell, the middle part of the co-extrusion mold is provided with a composite layer forming channel, the width of the forming channel at the mold entrance is smaller than the width of the composite layer forming channel, and a surface layer Plastic storage cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com