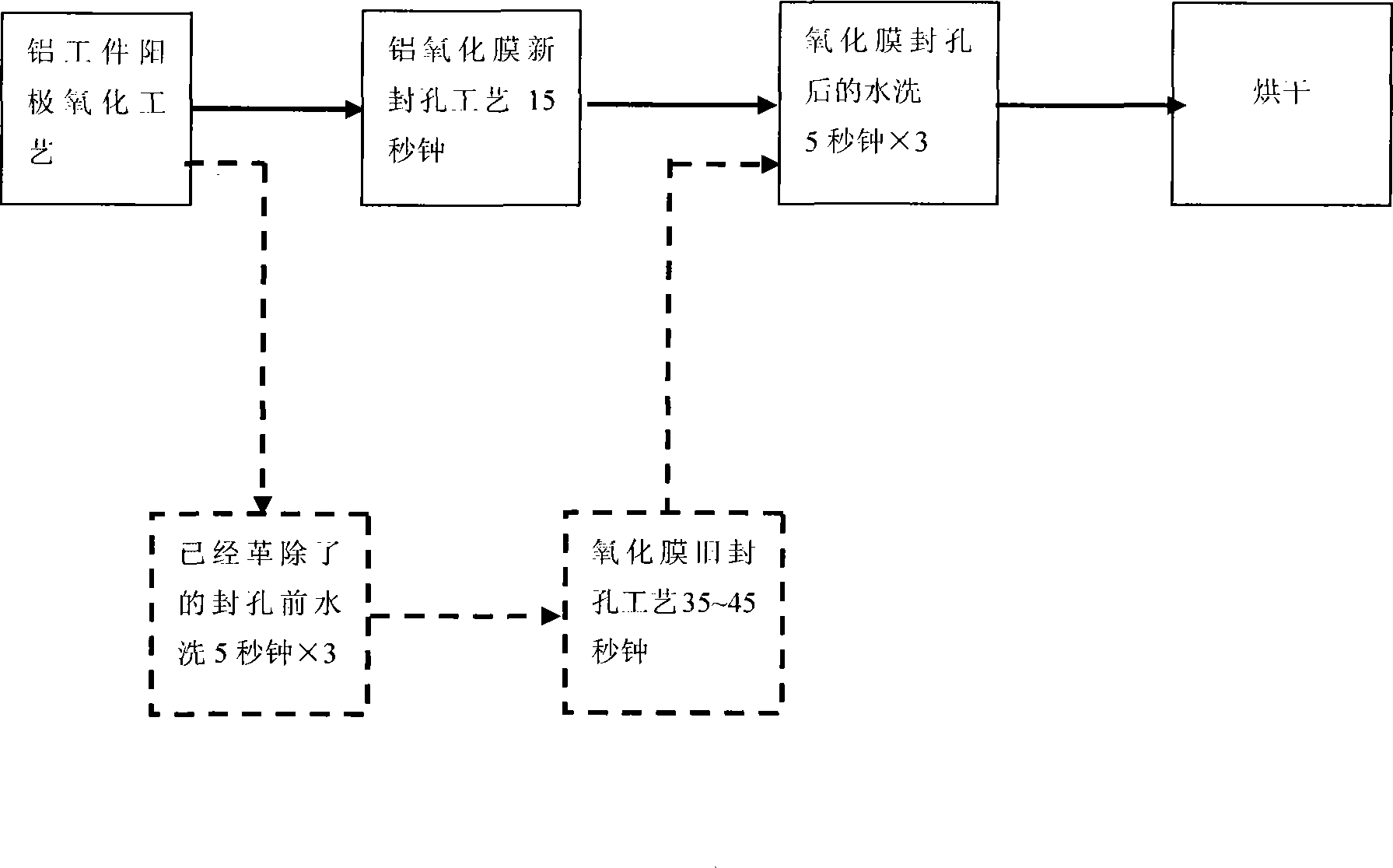

Anodic oxidation and sealing hole washing-free hole sealing technology

A technology of anodic oxidation and process technology, which is applied in the field of sealing technology without water washing between anodic oxidation and sealing, which can solve the problems of loss of sealing function and other problems, achieve shortening of working length, shortening of sealing process time, and reduction of process cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Sealing solution formula and formula principle

[0015] The liquid formula for the water-free sealing process between anodic oxidation and sealing of aluminum workpieces is divided into two parts: the basic sealing liquid formula and the sealing supplementary liquid formula.

[0016] 1. Process formula

[0017] A. Basic sealing fluid formula

[0018] Sodium dihydrogen phosphate NaH 2 PO 4 2H 2 O 50g / l

[0019] Aluminum Sulfate Al 2 (SO 4 ) 3 18H 2 O 1g / l

[0020] Potassium fluoride KF·2H 2 O 0.8g / l

[0021] After dosing, the naturally formed PH value of the solution is about 6, and the medicinal solution is slightly turbid. At this time, it is necessary to use 3 to 4N sulfuric acid H 2 SO 4 After lowering the pH value of the solution to 2, the medicinal solution will become very clear. Then use 6-8N sodium hydroxide NaOH solution to raise the pH value of the liquid to 4 o'clock, so that the liquid has reproduced a slight mixed corrosion. When this situat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com