Epoxy grafted acrylate self-layering connecting paint and preparation method thereof

An acrylate and connecting paint technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of decreased coating connection performance, easy layering of coating storage resin, unclear resin distribution, etc., to reduce the decline of bonding points. , Increase the mechanical bonding point, the effect of large structural differences

Active Publication Date: 2020-01-24

XIAMEN SUNRUI SHIP COATING

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The above patented epoxy resin and thermoplastic resin are simply compounded, and there are defects such as easy layering of the coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

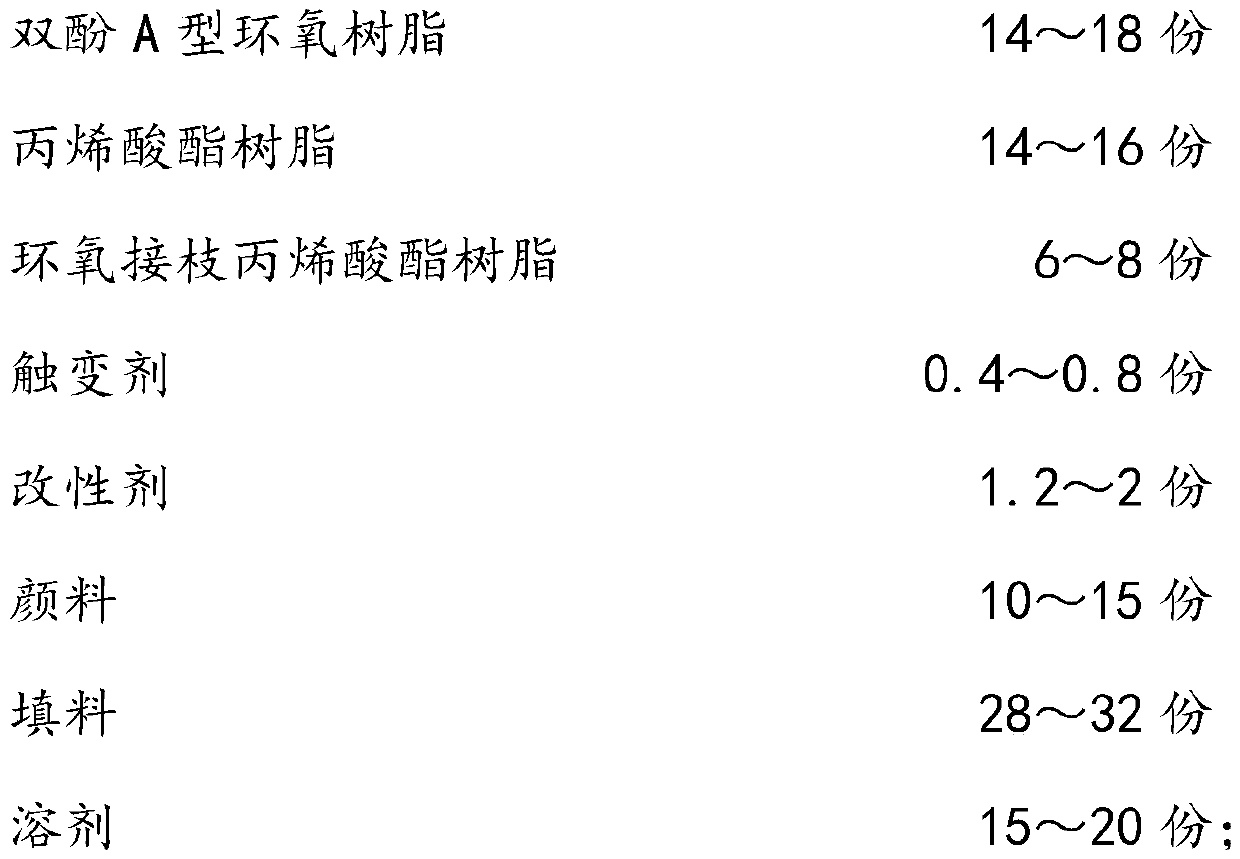

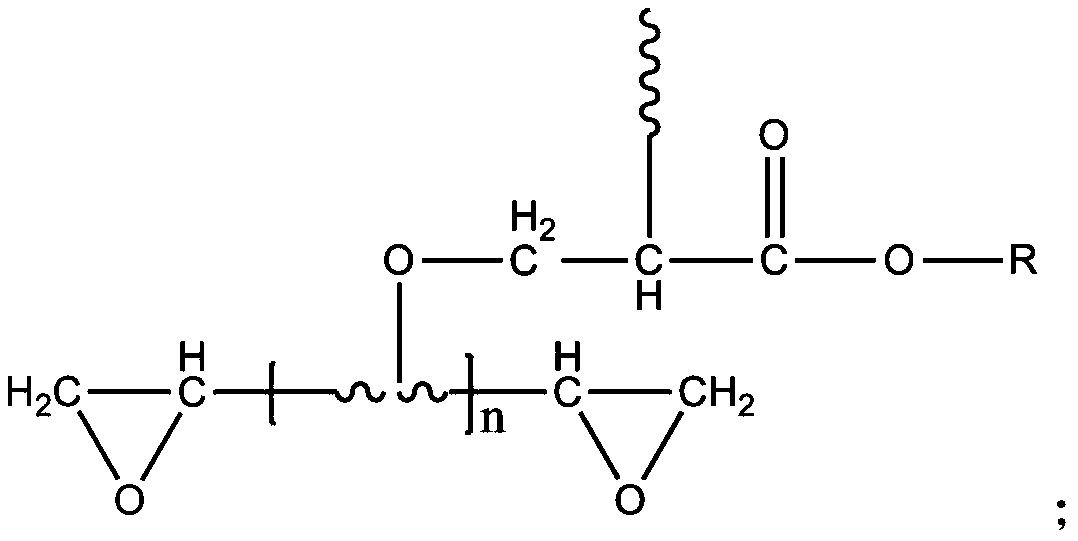

The invention relates to the technical field of antifouling coating materials, particularly to an epoxy grafted acrylate self-layering connecting paint and a preparation method thereof, wherein the epoxy grafted acrylate self-layering connecting paint comprises the following raw materials by mass: a bisphenol A type epoxy resin, an acrylate resin, an epoxy grafted acrylate resin, a thixotropic agent, a modifier, a pigment, a filler, a solvent and a curing agent. According to the invention, the epoxy grafted acrylate self-stratifying paint has excellent physical properties, can be matched withacrylate antifouling paints, obviously improves the connection performance, and can prolong the service life of the matched coating; and the connecting paint is low in preparation cost and wide in application range, and has high economic benefits.

Description

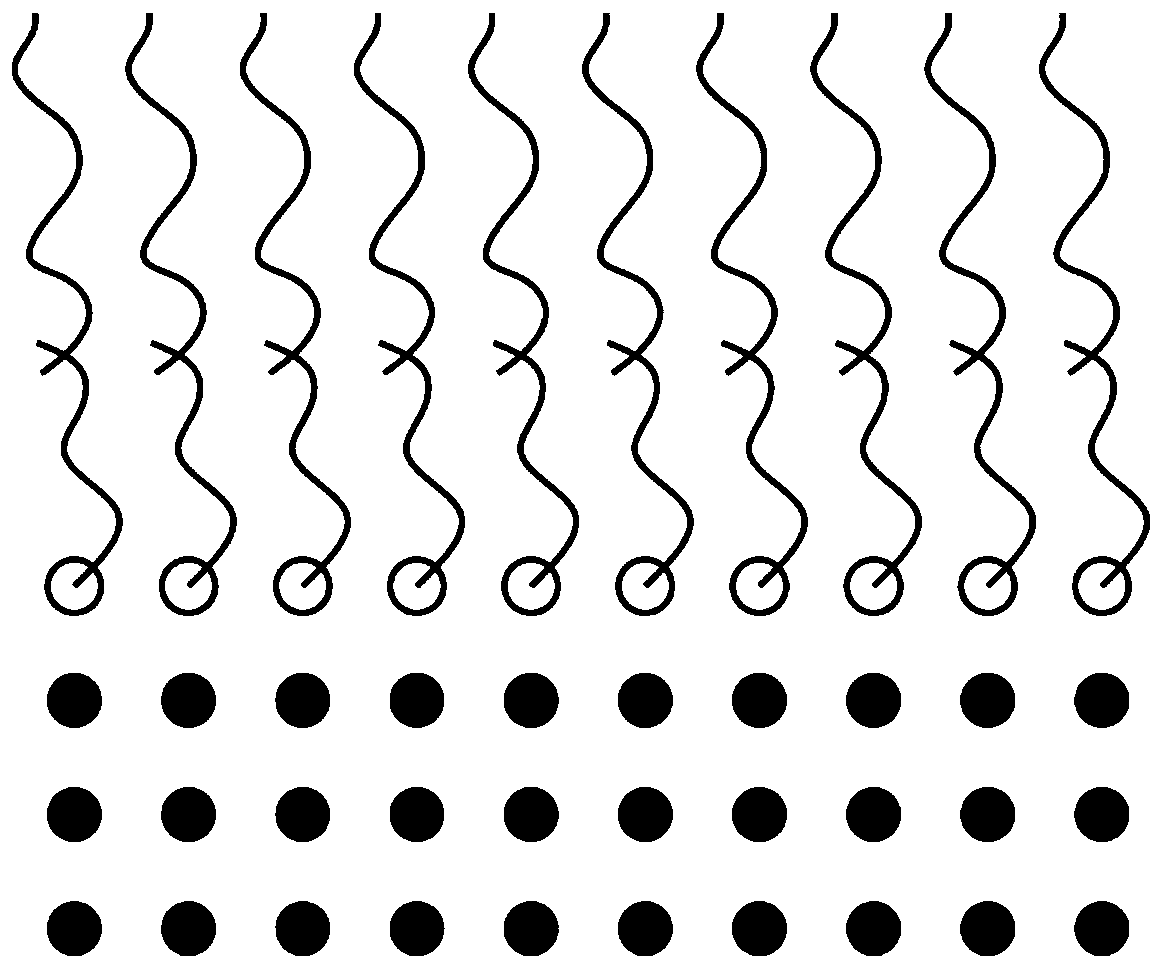

technical field [0001] The invention relates to the technical field of antifouling coatings, in particular to an epoxy grafted acrylate self-layering tie paint and a preparation method thereof. Background technique [0002] In order to ensure that the parts below the waterline of the hull shell are free from seawater corrosion and marine organisms, it is necessary to coat the hull with antirust paint and antifouling paint. However, due to the difference in raw materials and coating time between antirust and antifouling paints, antifouling paints cannot be directly coated on the antirust coating. Even if they can be coated, there are defects in adhesion performance. The general solution to the adhesion of the coating is to introduce a transition layer between the two coatings, that is, the connecting paint or the intermediate sealing paint. [0003] Since antifouling coatings are generally based on acrylic acid or acrylic modified resin, the connecting paint generally choose...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D133/04C09D151/08C09D7/62

CPCC08L2205/02C08L2205/035C09D133/04C09D163/00C09D7/62C08L33/04C08L51/08C08K9/06C08K9/04C08K3/013C08L63/00

Inventor 王胜龙李春光方大庆

Owner XIAMEN SUNRUI SHIP COATING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com