A method for reducing the volume shrinkage of inorganic polymer gelling materials

A technology of inorganic polymers and cementitious materials, which is applied in the direction of cement production, etc., can solve the problem of shrinkage and cracking of inorganic polymer cements, and there are few studies on the volume change of inorganic polymer cementitious materials. Problems such as too short to achieve the effect of improving volume stability and durability, improving volume stability, and saving natural resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

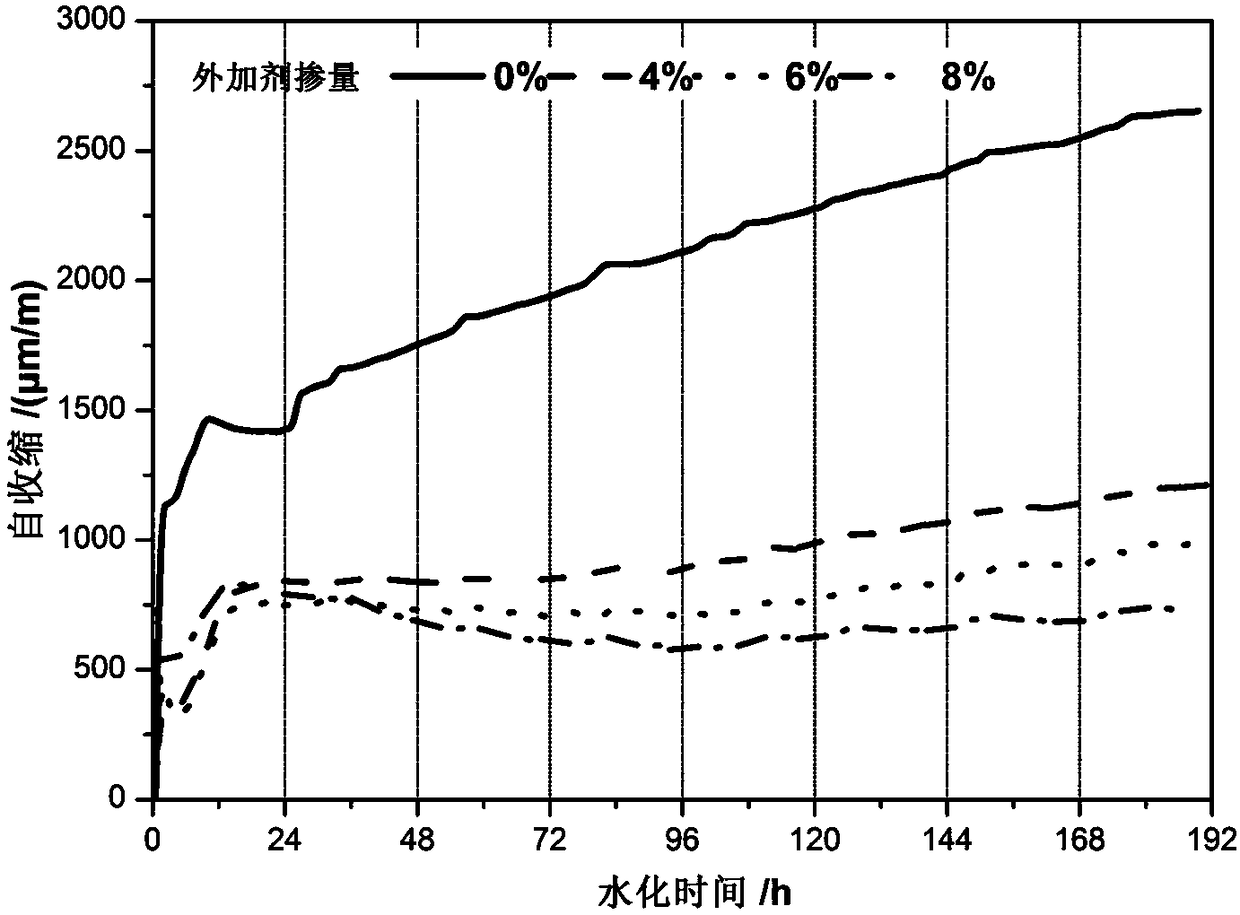

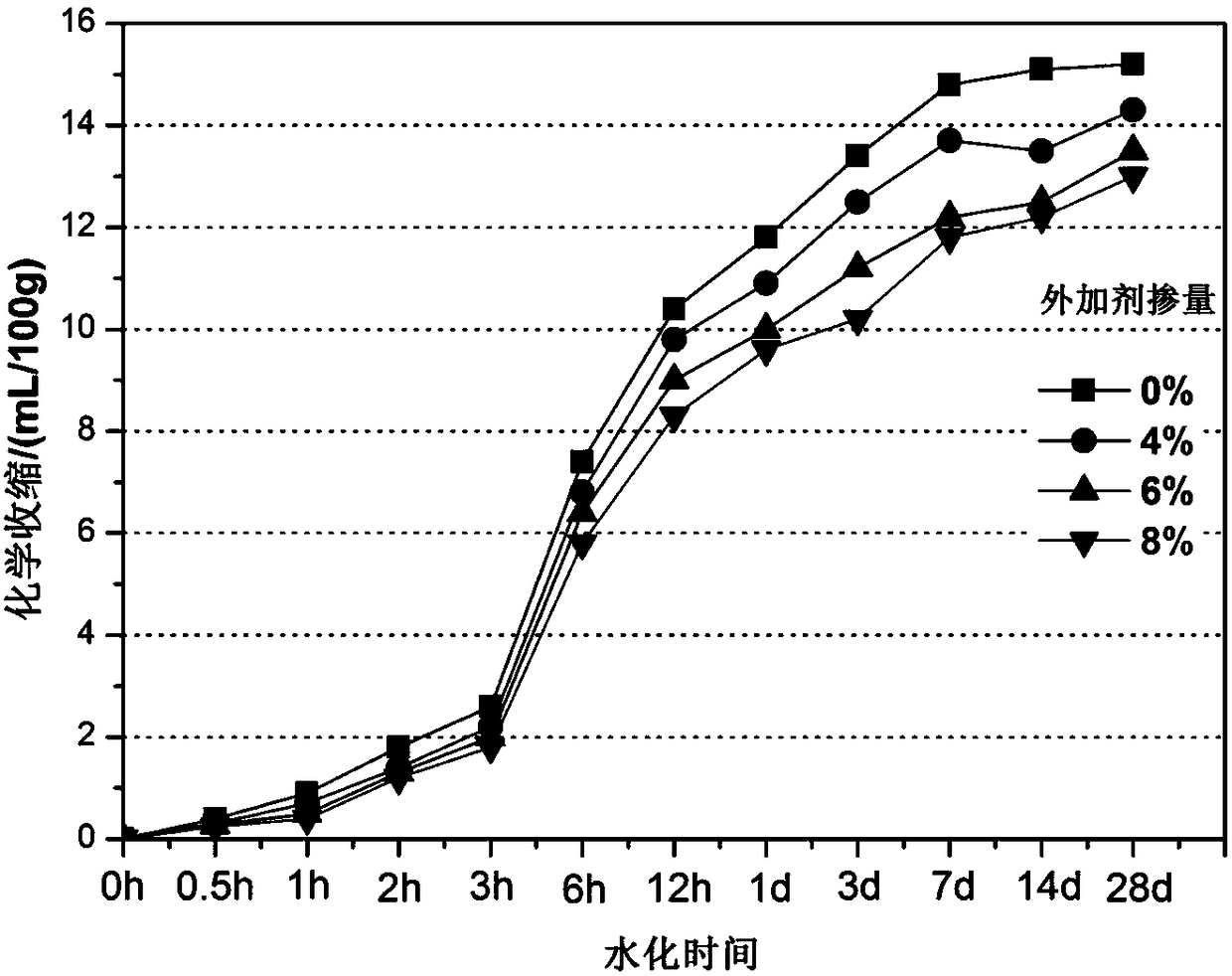

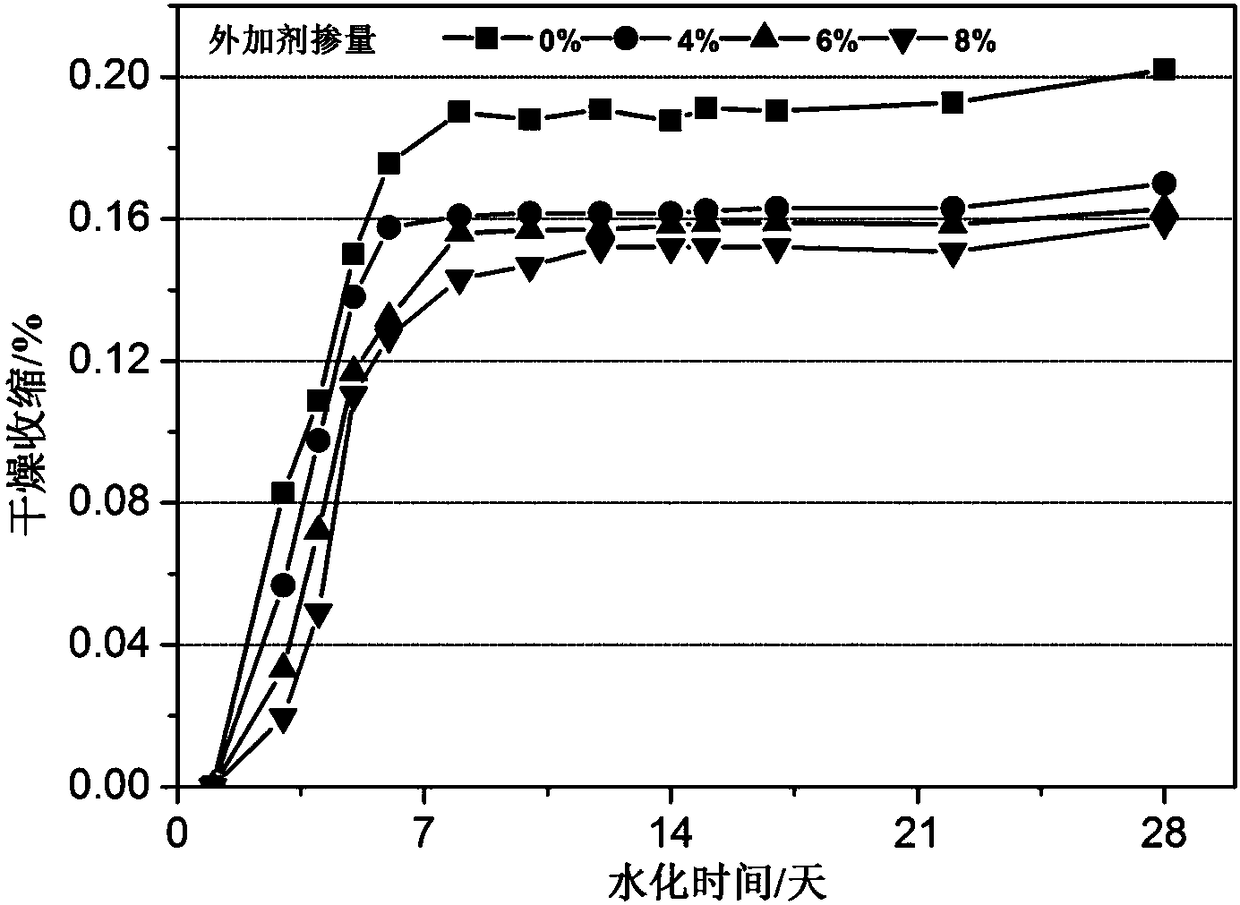

[0030] The shrinkage compensating admixture is added to the inorganic polymer gelling material, and the dosage of the admixture in the inorganic polymer is 4%, 6% and 8% respectively. The ratio of activated magnesia and nano silicon dioxide in the admixture is 1:1, wherein the activity of activated magnesia is 40s, the content of magnesia in activated magnesia is 95wt%, and the median diameter of nano silicon dioxide is 50nm. Mix the admixture with the inorganic polymer evenly, add water and mix to prepare a slurry, and test its autogenous shrinkage, chemical shrinkage and drying shrinkage respectively. At the same time, no shrinkage-compensating admixture is added to the inorganic polymer gelling material as a comparative example, that is, the admixtures in the inorganic polymer are respectively 0%. See the attached graph for the curves of the autogenous shrinkage of different dosages figure 1 , the curves of chemical shrinkage effects of different dosages are shown in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com