Construction technology of green concrete

A construction technology and concrete technology, which is applied in the direction of clay preparation equipment, construction material processing, cement mixing equipment, etc., can solve the problems of failure to meet the pumpability requirements of commercial concrete, failure of concrete cracking resistance, and increase of concrete slump and other problems, to achieve the effect of reducing shrinkage cracking, saving cement consumption, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Ratio of benchmark commercial concrete and additional stone

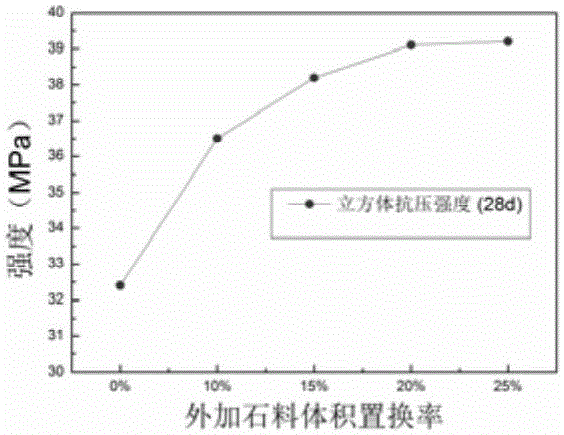

[0062] The ratio of the reference commercial concrete is the same as that of the reference commercial concrete in Comparative Example 1. The additional stone is continuously graded limestone with a moisture content of less than 0.6%wt and 5mm to 16mm. The volume of the added stones added to the ready-made concrete is 10% of the volume of the ready-made concrete (the volume replacement rate of the added stones is 10%).

[0063] 2. Construction technology

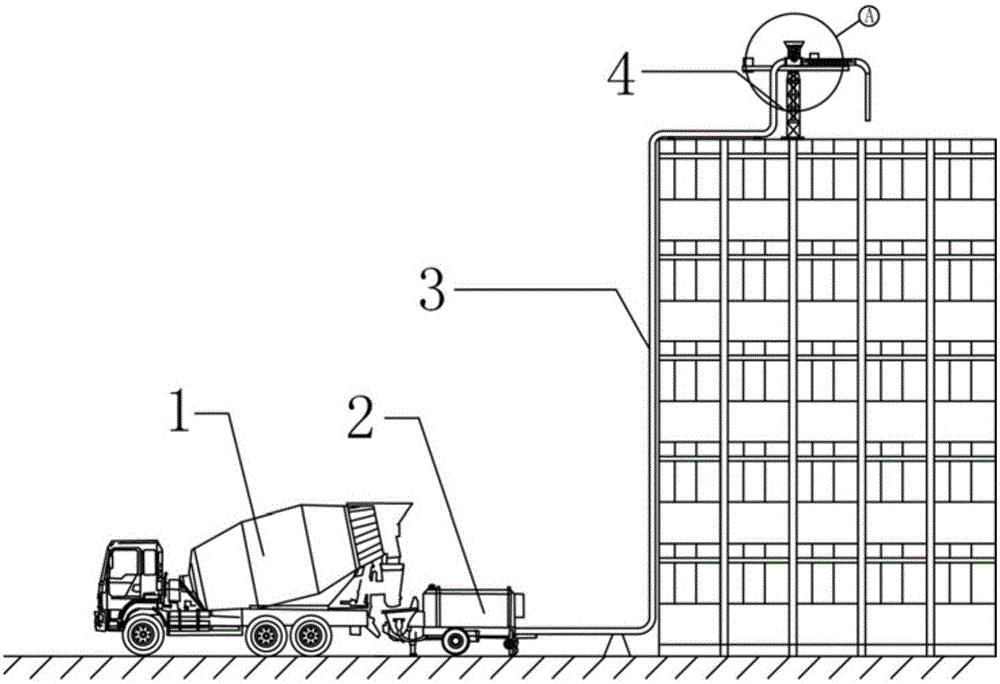

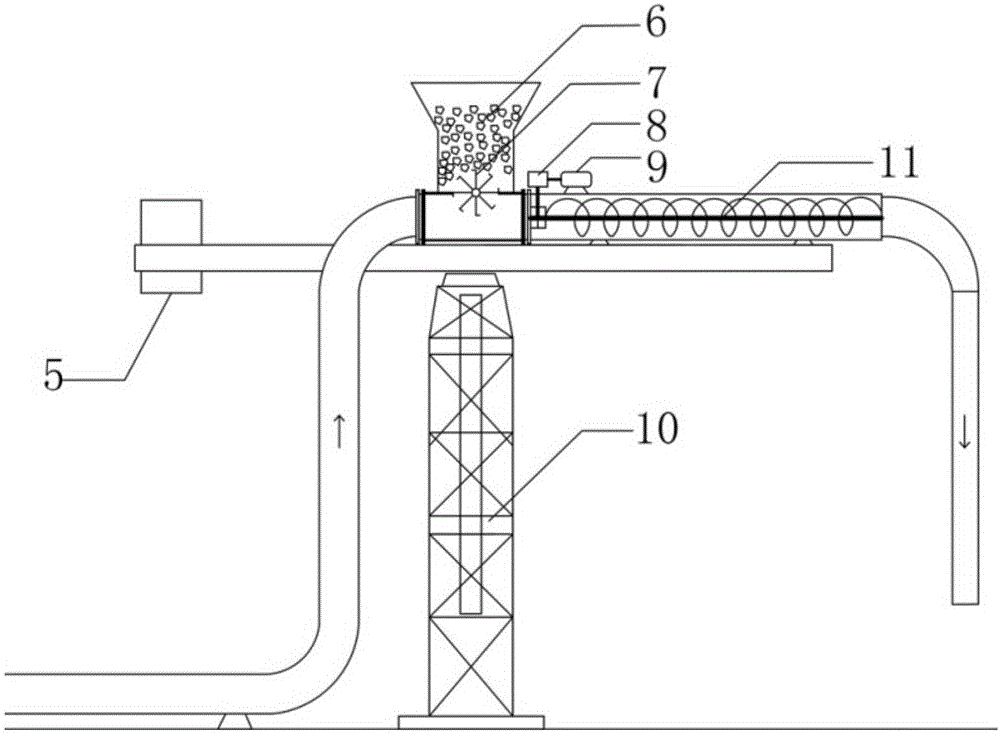

[0064] The commercial concrete is sent to the working face with the concrete delivery pump 2 and the concrete delivery pipeline 3, and the stone material storage bin 6 is installed above the opening between the end of the delivery pipeline 3 of the commercial concrete and the entrance of the screw mixing conveying device 11, and the ready-made concrete A rotating impeller 7 is set at the opening between the end 3 of the conveying pipeline and the entran...

Embodiment 2

[0066] 1. Ratio of benchmark commercial concrete and additional stone

[0067] The ratio of the benchmark commercial concrete is the same as that of the benchmark commercial concrete in Comparative Example 1; the additional stone is continuously graded limestone with a moisture content of less than 0.6%wt and 5mm to 16mm. The volume of the added stones added to the ready-made concrete is 15% of the volume of the ready-made concrete (the volume replacement rate of the added stones is 15%).

[0068] 2. The construction process is to deliver the ready-made concrete to the working surface with the concrete delivery pump 2 and the concrete delivery pipeline 3, and install the stone storage bin 6 above the opening between the end of the delivery pipeline 3 of the ready-made concrete and the entrance of the screw mixing delivery device 11 A rotating impeller 7 is set at the lower end of the feeding opening of the stone storage bin 6, and additional stones are added to the feeding ope...

Embodiment 3

[0070] 1. Ratio of benchmark commercial concrete and additional stone

[0071] The ratio of the benchmark commercial concrete is the same as that of the benchmark commercial concrete in Comparative Example 1; the additional stone is continuously graded limestone with a moisture content of less than 0.6%wt and 5mm to 16mm. The volume of the added stones added to the ready-made concrete is 20% of the volume of the ready-made concrete (the volume replacement rate of the added stones is 20%).

[0072] 2. The construction process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com