Medium-voltage tantalum powder and preparation method thereof

A technology of tantalum powder and raw powder, which is applied in the field of medium pressure tantalum powder and its preparation, can solve the problems of inability to meet the requirements of high-capacity tantalum powder, simple tantalum powder particle shape and coarse particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

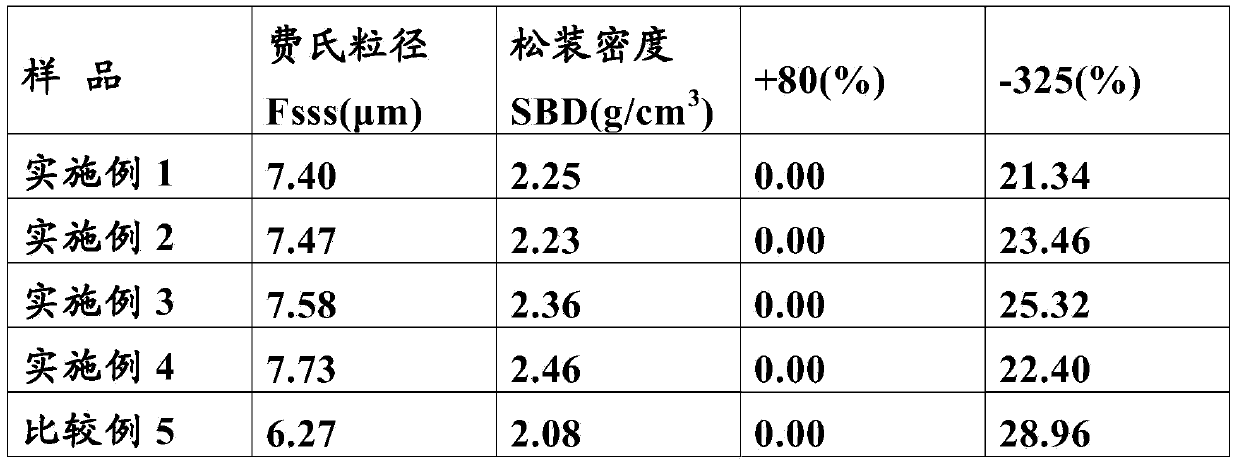

Embodiment 1

[0065] Load NaCl60kg into the reduction furnace, then raise the temperature according to the preset program, and add K from the feed port when the temperature reaches 920 °C 2 TaF 7 100Kg. After feeding, the temperature was raised to 930°C, and the holding time was calculated. After keeping warm at 930°C for 1 hour, increase the height of the stirring paddle and continue stirring, cool down to 820°C with blowing air, then start to inject sodium steadily, stir while injecting sodium, and keep the temperature at about 920°C. Wherein, the amount of sodium added to the reduction reaction is 31.5Kg. When the reaction temperature drops rapidly, it can be judged that the reduction reaction is over, and the reduction product is obtained.

[0066] The reduction product is crushed by a jaw crusher, and then washed and pickled to obtain the original tantalum powder. Washing and pickling treatment conditions are: first pass: use 10% HNO 3 + 0.5% HF acid wash for 2 hours, soak for 2 h...

Embodiment 2

[0069] Load 60kg of NaCl into the reduction furnace, then raise the temperature according to the preset program, and add K from the feed port when the temperature reaches 920°C 2 TaF 7 100Kg. After feeding, the temperature was raised to 930°C, and the holding time was calculated. After keeping warm at 930°C for 1 hour, increase the height of the stirring paddle and continue stirring, cool down to 820°C with blowing air, then start to inject sodium steadily, stir while injecting sodium, and keep the temperature at about 920°C. Wherein, the amount of sodium added to the reduction reaction is 31.8Kg. When the reaction temperature drops rapidly, it can be judged that the reduction reaction is over, and the reduction product is obtained.

[0070] The reduction product is crushed by a jaw crusher, and then washed and pickled to obtain the original tantalum powder. Washing and pickling treatment conditions are: first pass: use 10% HNO 3 + 0.5% HF acid wash for 2 hours, soak for ...

Embodiment 3

[0073] Load NaCl60kg into the reduction furnace, then raise the temperature according to the preset program, and add K from the feed port when the temperature reaches 920 °C 2 TaF 7 100Kg. After feeding, the temperature was raised to 930°C, and the holding time was calculated. After keeping warm at 930°C for 1 hour, increase the height of the stirring paddle and continue stirring, cool down to 820°C with blowing air, then start to inject sodium steadily, stir while injecting sodium, and keep the temperature at about 920°C. Wherein, the amount of sodium added to the reduction reaction is 32.0Kg. When the reaction temperature drops rapidly, it can be judged that the reduction reaction is over, and the reduction product is obtained.

[0074] The reduction product is crushed by a jaw crusher, and then washed and pickled to obtain the original tantalum powder. Washing and pickling treatment conditions are: first pass: use 10% HNO 3 + 0.5% HF acid wash for 2 hours, soak for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Fisherman's average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com