Method and device for vacuum pulsation drying poria cocos

A vacuum pulsation and drying technology, applied in the direction of drying gas arrangement, heating device, lighting device, etc., can solve the problems of low air and water vapor content, warping of the tray, affecting drying efficiency, etc., to promote volume shrinkage and drying speed. Fast, high material strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

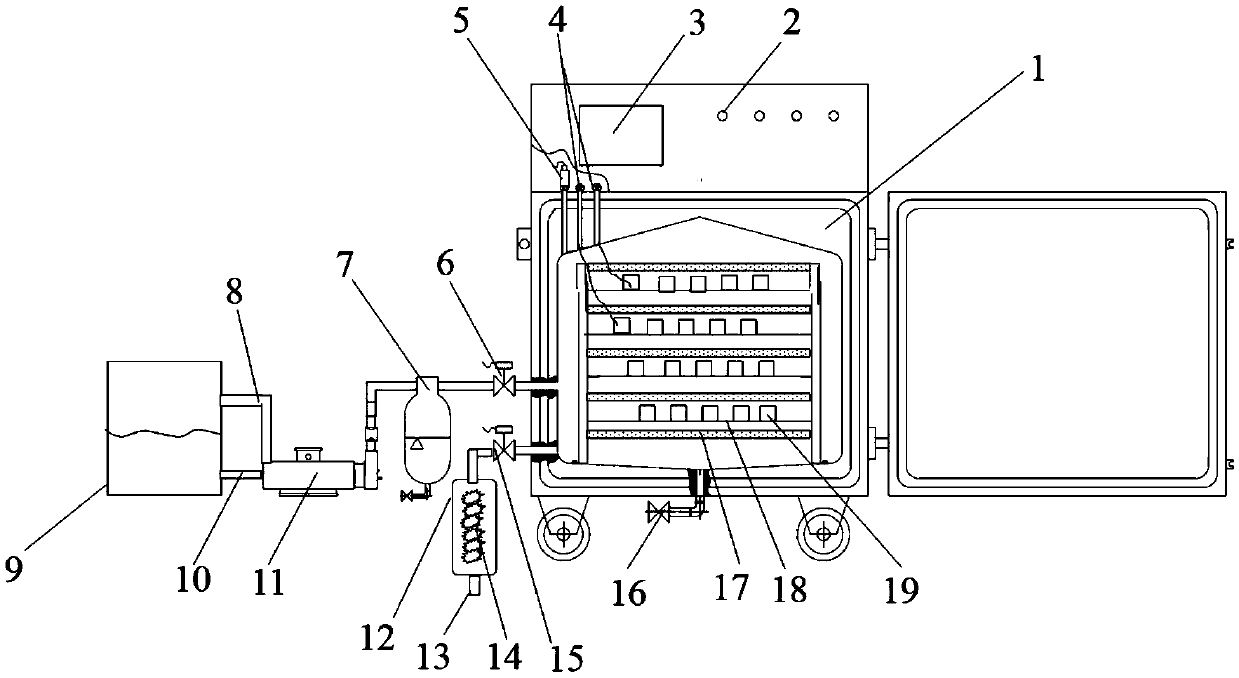

Image

Examples

Embodiment 1

[0071] a) Peel Poria cocos and cut into 15mm 3 After the Poria cocos dices 19, be placed on the charging tray 18 in the vacuum pulse drying device.

[0072] b) Start the device for vacuum pulsation drying Poria cocos, and set the range of absolute vacuum in drying chamber 1, material temperature, pulsation ratio and continuous drying time.

[0073] Among them, the minimum absolute vacuum range of drying chamber 1 is 0, and the maximum value is 6kPa; the material temperature is 60°C; the pulse ratio is the ratio of the time in normal pressure state of drying chamber 1 to the time in vacuum state, and the ratio is 4 / 15; continuous drying The time is 6 hours. The air pressure value in the normal pressure state is the local actual atmospheric pressure.

[0074] c) Carry out vacuum pulse drying and heating to Poria 19 according to the set time;

[0075] In the vacuum state of the drying process, the main control part controls the intake valve 15 to close according to the pressur...

Embodiment 2

[0082] a) Peel Poria cocos and cut into 12mm 3 After the Poria cocos dices 19, be placed on the charging tray 18 in the vacuum pulse drying device.

[0083] b) Start the device for vacuum pulsation drying Poria cocos, and set the range of absolute vacuum in drying chamber 1, material temperature, pulsation ratio and continuous drying time.

[0084] Wherein, the minimum value of the absolute vacuum range of the drying chamber 1 is 0, and the maximum value is 5kPa; the material temperature is 70°C; the pulse ratio is the ratio of the normal pressure state time to the vacuum state time of the drying chamber 1, and the ratio is 4 / 15 ; Continuous drying time is 5 hours. The air pressure value in the normal pressure state is the local actual atmospheric pressure.

[0085] c) Carry out vacuum pulse drying and heating to Poria 19 according to the set time;

[0086] In the vacuum state of the drying process, the main control part controls the intake valve 15 to close according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com