Impulse-pressurzing sintering furnace

A pressurized sintering and sintering furnace technology, applied in furnaces, furnace cooling, muffle furnaces, etc., can solve the problem of powder shrinkage, material densification cannot be grasped in time, and the degree of densification of sintered bodies and mechanical properties are restricted. Sintering of high-performance materials and other issues to achieve excellent performance, rapid densification, and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

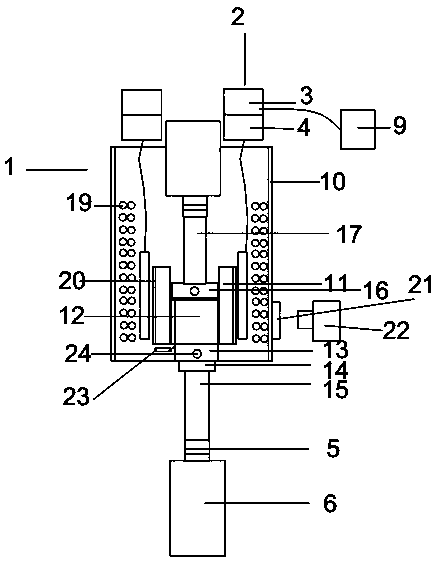

[0020] refer to Figure 1-2 , the present invention will be further explained below in conjunction with specific embodiment.

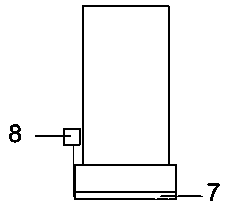

[0021] A pulse pressure sintering furnace, comprising a sintering furnace 1 and a pulse pressure device 2, the pulse pressure device 2 includes a pulse generator 3, a pulse converter 4, a servo valve 5, a servo cylinder 6, a force sensor 7, a sensing signal The transmitter 8, the pulse generator 3 is connected to the pulse converter 4, the opening of the servo cylinder 6 is connected to the servo valve 5, the force sensor 7 is connected to the sensor signal transmitter 8, the pulse converter 4, the servo valve 5 and the sensor signal transmitter The conveyors 8 are all connected by the sintering controller 9. The sintering furnace 1 includes a furnace body 10. The furnace body 10 is a cylindrical shape. It is the lower pressure head 13 and the lower pressure head fixing seat 14, the lower pressure head fixing seat 14 is connected with the lower pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com