A kind of conductive silver glue and its preparation method and use

A technology of conductive silver glue and application, which is applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of reducing bond strength and operating performance, poor storage and transportation performance, and increasing the viscosity of conductive adhesives, etc., to achieve Improve handling performance, improve electrical conductivity, and promote the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

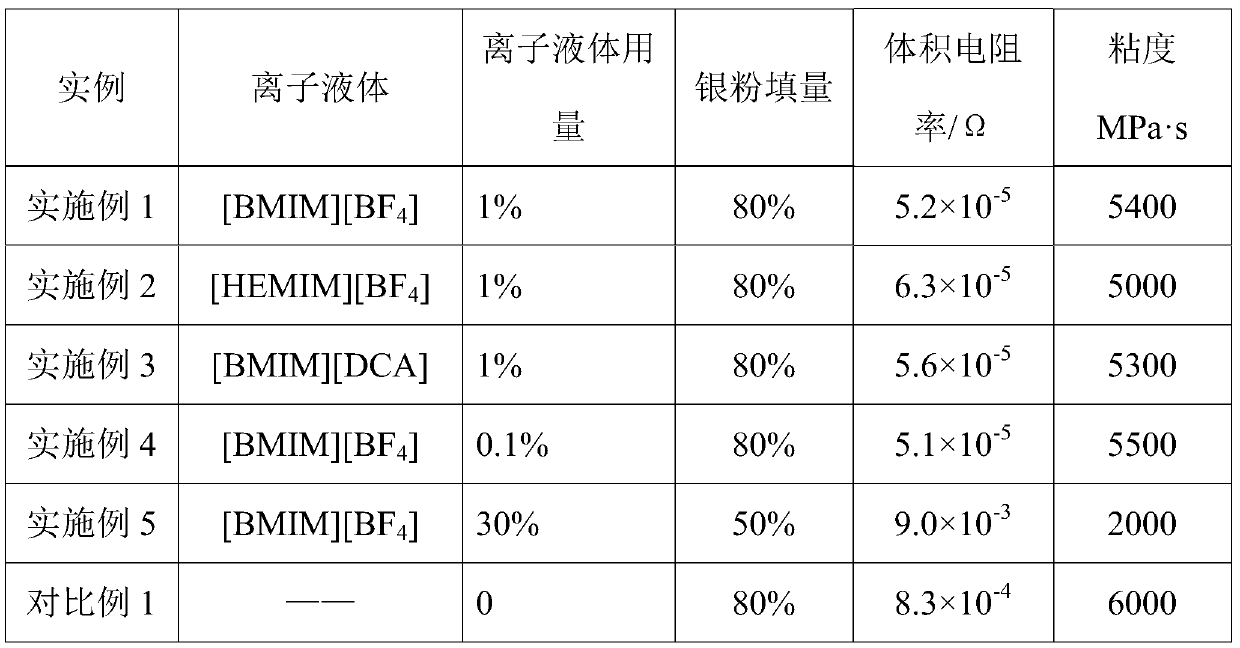

Examples

Embodiment 1

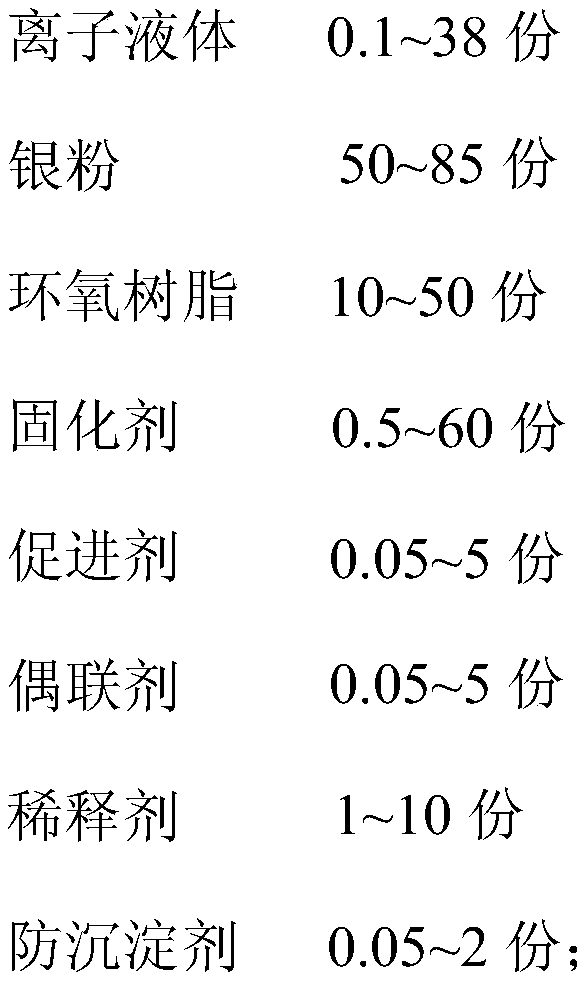

[0051] A kind of conductive silver paste comprises the following components by weight parts:

[0052] Ionic liquids ([BMIM][BF 4 ]) 1 copy

[0053] Silver powder (1~8μm) 80 parts

[0054] Epoxy resin (bisphenol A epoxy resin 828E) 16 parts

[0055] Curing agent (dicyandiamide) 1 part

[0056] Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.1 parts

[0057] Coupling agent (KH560) 0.1 part

[0058] Thinner (1,4-butanediol diglycidyl ether) 1.75 parts

[0059] 0.05 part of anti-precipitation agent (fumed silica);

[0060] Preparation:

[0061] Fill the ionic liquid into the epoxy resin according to the formula, stir and defoam, so that the ionic liquid is fully dispersed, and the first base resin with uniform components is made; diluent, anti-precipitation agent, coupling agent, curing agent, accelerator Add the agent to the first base resin according to the formula, grind it evenly with a three-roll mill after mixing, mix and defoam, and make the second base resin...

Embodiment 2

[0073] The difference with Example 1 is that the conductive silver paste comprises the following components in parts by weight:

[0074] Ionic liquids ([HEMIM][BF 4 ]) 1 copy

[0075] Silver powder (1~10μm) 80 parts

[0076] Epoxy resin (bisphenol A epoxy resin 828E) 16 parts

[0077] Curing agent (dicyandiamide) 1 part

[0078] Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.1 parts

[0079] Coupling agent (KH560) 0.1 part

[0080] Thinner (1,4-butanediol diglycidyl ether) 1.75 parts

[0081] 0.05 part of anti-precipitation agent (fumed silica);

Embodiment 3

[0083] The difference with Example 1 is that the conductive silver paste comprises the following components in parts by weight:

[0084] 1 part of ionic liquid ([BMIM][DCA]);

[0085] Silver powder (3 ~ 6μm) 80 parts;

[0086] Epoxy resin (bisphenol A epoxy resin 828E) 16 parts

[0087] Curing agent (dicyandiamide) 1 part

[0088] Accelerator (1-cyanoethyl-2-ethyl-4-methylimidazole) 0.1 parts

[0089] Coupling agent (KH560) 0.1 part

[0090] Thinner (1,4-butanediol diglycidyl ether) 1.75 parts

[0091] 0.05 part of anti-precipitation agent (fumed silica);

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com