Continuous coating mechanism for solvent-free curing adhesive coating layer

A curing glue, solvent-free technology, applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., can solve the problem of low transfer rate of solvent-free glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

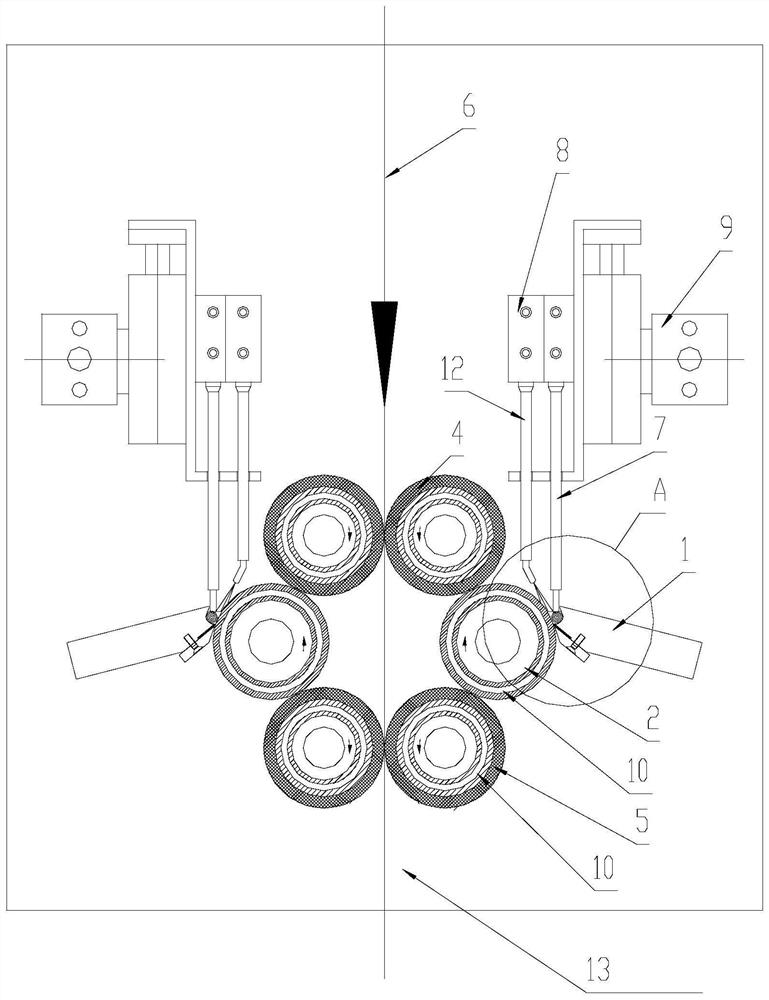

[0038]This embodiment relates to a continuous coating mechanism for continuous coating of solvent-free curing glue (hereinafter also referred to as curing glue) on both sides of a flat product. The two groups of continuous coating mechanisms pass through continuously. During the passing process, the solvent-free curing glue is continuously coated on the surface of the flat product by the continuous coating mechanism.

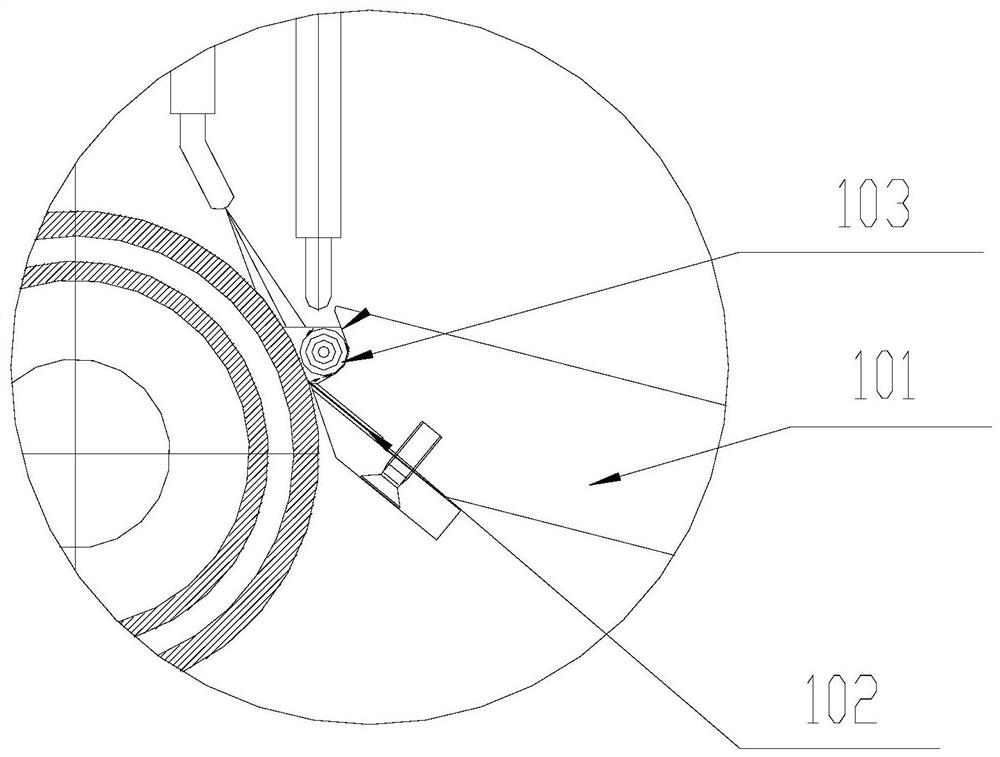

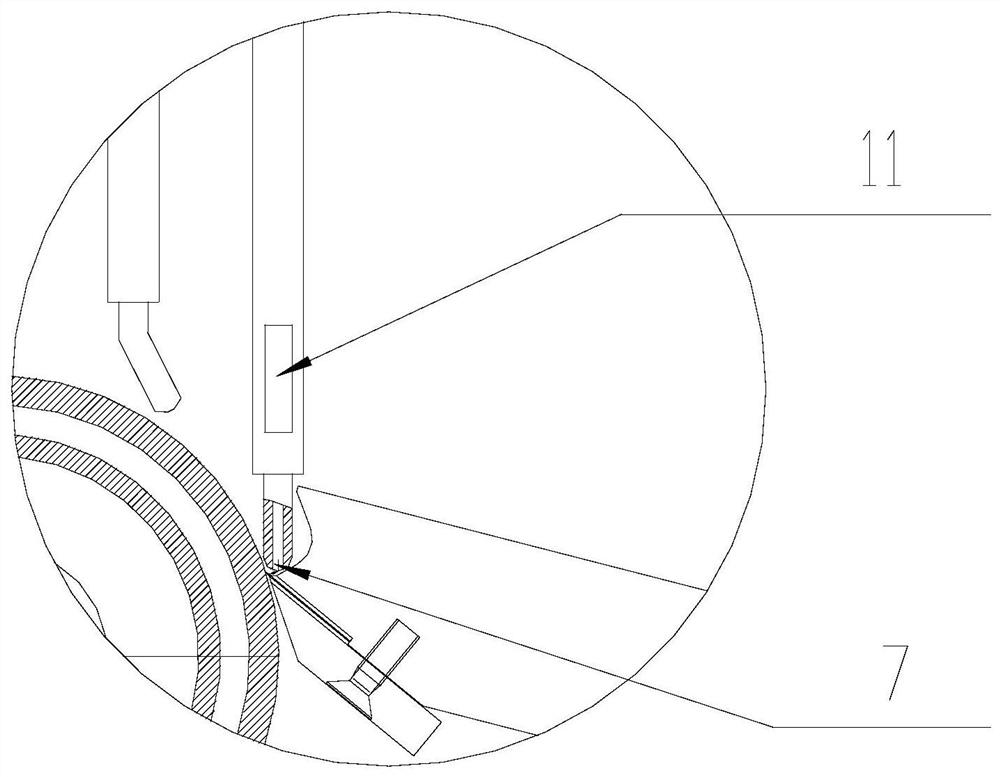

[0039] The continuous coating mechanism includes an anilox roller 2, two rubber transfer rollers (4, 5), a glue supply nozzle 12, a scraper mechanism 1 and a cleaning spray suction pipe 7, two rubber transfer rollers (4, 5). 5) are smooth rollers, which are respectively arranged at the upper and lower positions of the anilox roller 2 and are in rolling contact with the anilox roller 2 respectively. The glue supply nozzle 12 is connected with the automatic glue supply system 8. The function of the automatic glue supply system 8 is to quantitatively supply glue to...

Embodiment 2

[0051] like Figure 5 As shown in the figure, the anilox roller can be designed to be able to rotate both clockwise and counterclockwise. Therefore, two scrapers need to be set up to cooperate with the anilox roller 2 when the anilox roller 2 rotates clockwise. Works in conjunction with anilox roll 2 rotating counterclockwise. Makes anilox roll gluing more flexible.

Embodiment 3

[0053] This embodiment involves the matching sizing structure of the anilox roller 2 and the pressing roller 14, such as Figure 7 As shown in the figure, the anilox roller 2 is provided with a constant temperature spacer 10, and the pressure roller 14 is also provided with a constant temperature spacer 10. A flat product such as a film is continuously wound around the pressing roller 14, and the pressing roller 14 squeezes the film to the surface of the anilox roller 2. During the extrusion process, the solvent-free cured glue in the grid on the surface of the anilox roller is squeezed onto the surface of the film.

[0054] In this embodiment, the anilox roller 2 rotates counterclockwise, the scraper mechanism 1 is arranged on the left side of the anilox roller 2, and the pressing roller 14 rotates clockwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com