Super-weather-resistant environment-friendly ultraviolet light curing pressure-sensitive adhesive for high-end waterproof materials, and preparation method thereof

A waterproof material, ultraviolet light technology, applied in the direction of adhesives, ester copolymer adhesives, mineral oil hydrocarbon copolymer adhesives, etc. Insufficient heat and other problems, to achieve the effect of large cohesion, suitable for large-scale production, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

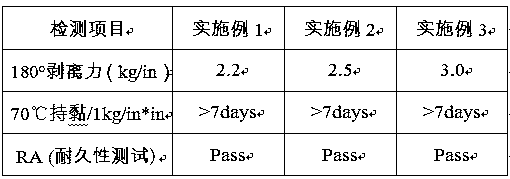

Embodiment 1

[0039] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, comprising the following components in parts by weight:

[0040] 45 parts of butyl acrylate;

[0041] 10 parts of isooctyl acrylate;

[0042] 1 part acrylic acid;

[0043] 4 parts of hydroxyethyl acrylate;

[0044] 64 parts of ethyl acetate;

[0045] Benzoyl peroxide 0.8 parts;

[0046] Dilauroyl peroxide 2 parts;

[0047] 10 parts of petroleum resin;

[0048] 0.3 parts of photoinitiator.

[0049] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, including the following process:

[0050] A. Put 45 parts of butyl acrylate, 10 parts of isooctyl acrylate, 1 part of acrylic acid, 4 parts of hydroxyethyl acrylate and 60 parts of ethyl acetate into a three-necked round-bottomed flask, and then ...

Embodiment 2

[0058] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, comprising the following components in parts by weight:

[0059] 50 parts of butyl acrylate;

[0060] 10 parts of isooctyl acrylate;

[0061] 2 parts of hydroxyethyl acrylate;

[0062] 80 parts of ethyl acetate;

[0063] Benzoyl peroxide 1.6 parts;

[0064] Dilauroyl peroxide 3 parts;

[0065] 20 parts of petroleum resin;

[0066] 0.8 parts of photoinitiator.

[0067] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, including the following process:

[0068] A. Put 50 parts of butyl acrylate, 5 parts of isooctyl acrylate, 2 parts of hydroxyethyl acrylate, and 70 parts of ethyl acetate into a three-necked round-bottomed flask, and then connect the three-necked round-bottomed flask to a stir...

Embodiment 3

[0076] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, comprising the following components in parts by weight:

[0077] 20 parts of butyl acrylate;

[0078] 40 parts of isooctyl acrylate;

[0079] 1 part acrylic acid;

[0080] 80 parts of ethyl acetate;

[0081] Benzoyl peroxide 2 parts;

[0082] Dilauroyl peroxide 1.5 parts;

[0083] 20 parts of petroleum resin;

[0084] 1.2 parts of photoinitiator.

[0085] A super-weather-resistant and environment-friendly UV-curable pressure-sensitive adhesive applied to high-end waterproof materials and a preparation method thereof, including the following process:

[0086] A. Put 20 parts of butyl acrylate, 40 parts of isooctyl acrylate, 1 part of acrylic acid and 65 parts of ethyl acetate into a three-neck round bottom flask, and then connect the three-neck round bottom flask to the stirrer, thermometer and condense...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com