Graphene polymer pressure sensitive composite material and preparation method thereof

A technology of pressure-sensitive composite materials and polymers, which is applied in the field of graphene polymer pressure-sensitive composite materials and its preparation, can solve problems affecting performance, easy peeling, etc., and achieve durability problems, low cost, and simple process methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve graphite oxide in water, stir for 30 minutes, and ultrasonicate for 2 hours to prepare a certain concentration of graphene oxide solution: the concentration range is 4 mg / ml;

[0033] (2) Take 50ml of graphene oxide solution, put it in a 100ml reaction kettle, and conduct a hydrothermal reaction at 160°C for 24h. Obtain a three-dimensional network graphene columnar body;

[0034] (3) 2-Chlorobutadiene (1.3) with a solids content of 29% was used. Place the graphene cylinders in a watch glass of suitable size. Add the polymer emulsion and let it soak in the polymer emulsion for 12h.

[0035] (4) Take out the composite material, and use a vacuum freeze dryer to carry out vacuum freeze-drying for 24 hours, and the vacuum degree is less than 0.09Pa to obtain a three-dimensional network graphene polymer composite material.

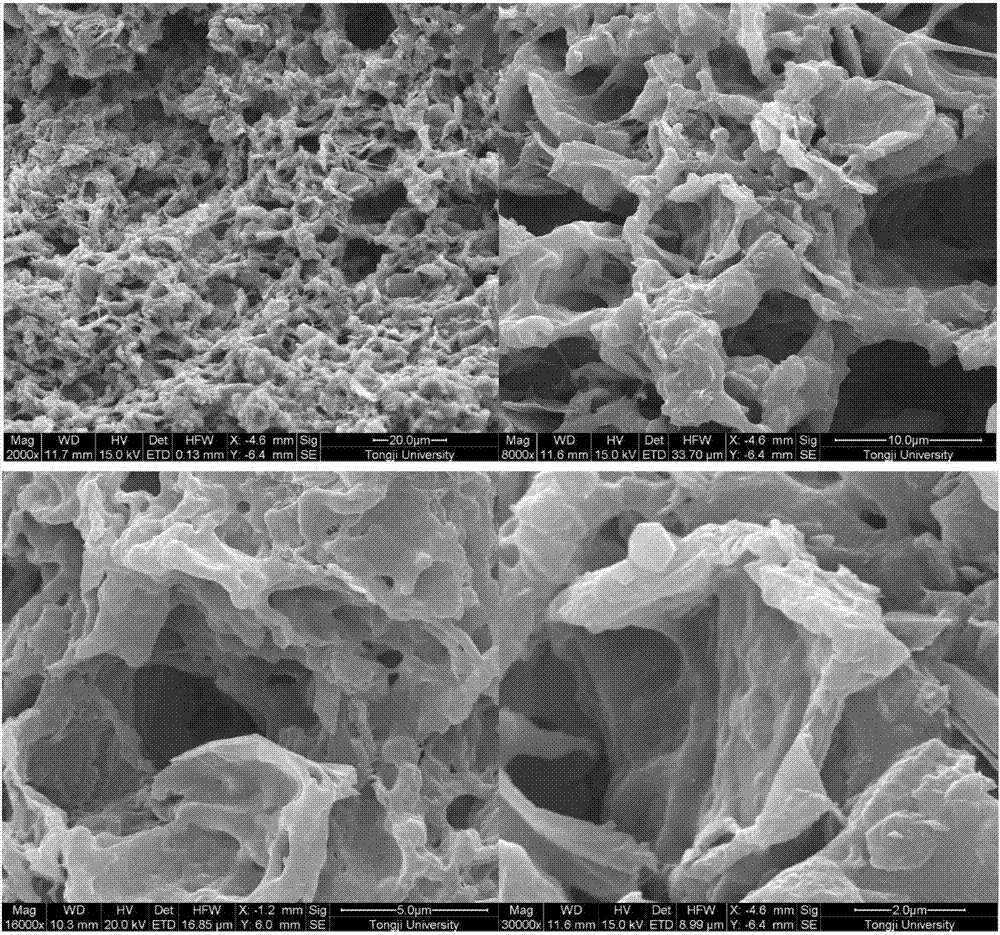

[0036] The scanning electron microscope picture of the graphene polymer composite material prepared by the present embodiment is as follo...

Embodiment 2

[0038] (1) Dissolve graphite oxide in water, stir for 30 minutes, and ultrasonicate for 2 hours to prepare a certain concentration of graphene oxide solution: the concentration range is 4 mg / ml;

[0039] (2) Take 50ml of graphene oxide solution, put it in a 100ml reaction kettle, and conduct a hydrothermal reaction at 160°C for 24h. Obtain a three-dimensional network graphene columnar body;

[0040] (3) 2-Chlorobutadiene (1.3) with a solids content of 58% was used. Place the graphene cylinders in a watch glass of suitable size. Add the polymer emulsion and let it soak in the polymer emulsion for 12h.

[0041] (4) Take out the composite material, and use a vacuum freeze dryer to carry out vacuum freeze-drying for 24 hours, and the vacuum degree is less than 0.09Pa to obtain a three-dimensional network graphene polymer composite material.

[0042] The stress-strain curve of the composite material in embodiment 2 is as Figure 4 It is shown that when the stress is 0-1.7kPa, t...

Embodiment 3

[0046] (1) Dissolve graphite oxide in water, stir for 30 minutes, and ultrasonicate for 2 hours to prepare a certain concentration of graphene oxide solution: the concentration range is 4 mg / ml;

[0047](2) Take 50ml of graphene oxide solution, put it in a 100ml reaction kettle, and conduct a hydrothermal reaction at 180°C for 24h. Obtain a three-dimensional network graphene columnar body;

[0048] (3) 2-Chlorobutadiene (1.3) with a solids content of 58% was used. Place the graphene cylinders in a watch glass of suitable size. Add the polymer emulsion and let it soak in the polymer emulsion for 12h.

[0049] (4) Take out the composite material, and use a vacuum freeze dryer to carry out vacuum freeze-drying for 24 hours, and the vacuum degree is less than 0.09Pa to obtain a three-dimensional network graphene polymer composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com