Water-based environment-friendly sealing adhesive and preparation method thereof

A sealing glue, water-based technology, used in adhesives, natural rubber adhesives, monocarboxylic acid ester copolymer adhesives, etc., can solve the problem of increasing the use cost of packaging manufacturers, operating risks, and the quality of BOPP film is not guaranteed, etc. problems, to achieve the effect of improved performance, improved bonding conditions, excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

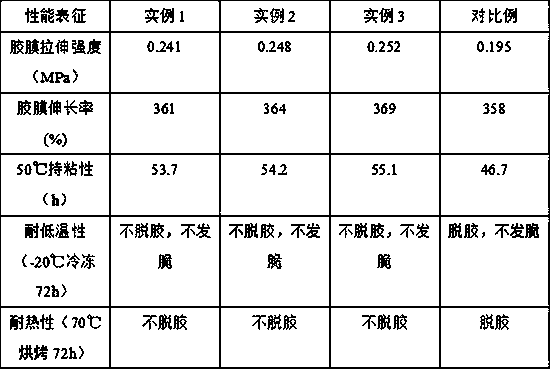

Examples

example 1

[0028] Take 10g of functional additive AMP-95, 10g of emulsifier dioctyl sodium sulfosuccinate, stir and mix at 300-400r / min to obtain a wetting agent, take 400g of polyacrylate emulsion and put it into a stirring tank. At 40°C, stir at 100r / min for 10min, then add 0.2g of defoamer, 100g of rosin terpene resin emulsion, 150g of self-crosslinking emulsion, and continue stirring for 20min to obtain a premix. Take 50g of natural rubber latex and 75g of water-based SBS emulsion , add 0.2g defoamer to the premix, stir at 100r / min for 10min at 40°C, then add 1g wetting agent, 1g preservative, stir at 200r / min for 30min to obtain a composite emulsion, at 40°C Add ammonia water with a mass fraction of 10% to the composite emulsion, and continue to stir until the pH of the composite emulsion reaches 7.0, and adjust the viscosity to 8000mPa·s. After mixing evenly, filter it with a 100-mesh filter, and pack it out to obtain a water-based environmentally friendly sealing glue.

example 2

[0030] Take 15g of functional additive AMP-95, 15g of emulsifier dioctyl sodium sulfosuccinate, and stir and mix at 350r / min to obtain a wetting agent. Take 450g of polyacrylate emulsion and put it into a stirring tank. Stir at 150r / min for 15min, then add 0.6g defoamer, 120g rosin terpene resin emulsion, 180g self-crosslinking emulsion, and continue stirring for 25min to obtain a premix. Take 60g natural rubber latex, 80g water-based SBS emulsion, 0.6 Add g defoamer to the premix, stir at 150r / min for 15min at 45°C, then add 1g of wetting agent and 1g of preservative, stir at 250r / min for 35min to obtain a composite emulsion, and mix at 45°C Ammonia water with a mass fraction of 10% was added dropwise to the emulsion, continuously stirred until the pH of the composite emulsion reached 7.2, and the viscosity was adjusted to 10000mPa·s. After mixing evenly, it was filtered with a 100-mesh filter, and the material was packaged to obtain a water-based environmentally friendly seal...

example 3

[0032] Take 20g of functional additive AMP-95, 20g of emulsifier dioctyl sodium sulfosuccinate, stir and mix at 400r / min to obtain a wetting agent, take 500g of polyacrylate emulsion and put it into a stirring tank, and heat it at 50°C Stir at 200r / min for 20min, then add 1.0g defoamer, 150g rosin terpene resin emulsion, 200g self-crosslinking emulsion, and continue stirring for 30min to obtain a premix. Take 75g natural rubber latex, 100g water-based SBS emulsion, 1.0 Add g defoamer to the premix, stir at 200r / min for 20min at 50°C, then add 2g of wetting agent and 2g of preservative, and stir for 40min at 300r / min to obtain a composite emulsion, which is mixed at 50°C Ammonia water with a mass fraction of 10% was added dropwise to the emulsion, continuously stirred until the pH of the composite emulsion reached 7.5, and the viscosity was adjusted to 12000mPa·s. After mixing evenly, it was filtered with a 100-mesh filter, and the material was packaged to obtain a water-based e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com