Rewetting repairable modified waterborne white latex and preparation method thereof

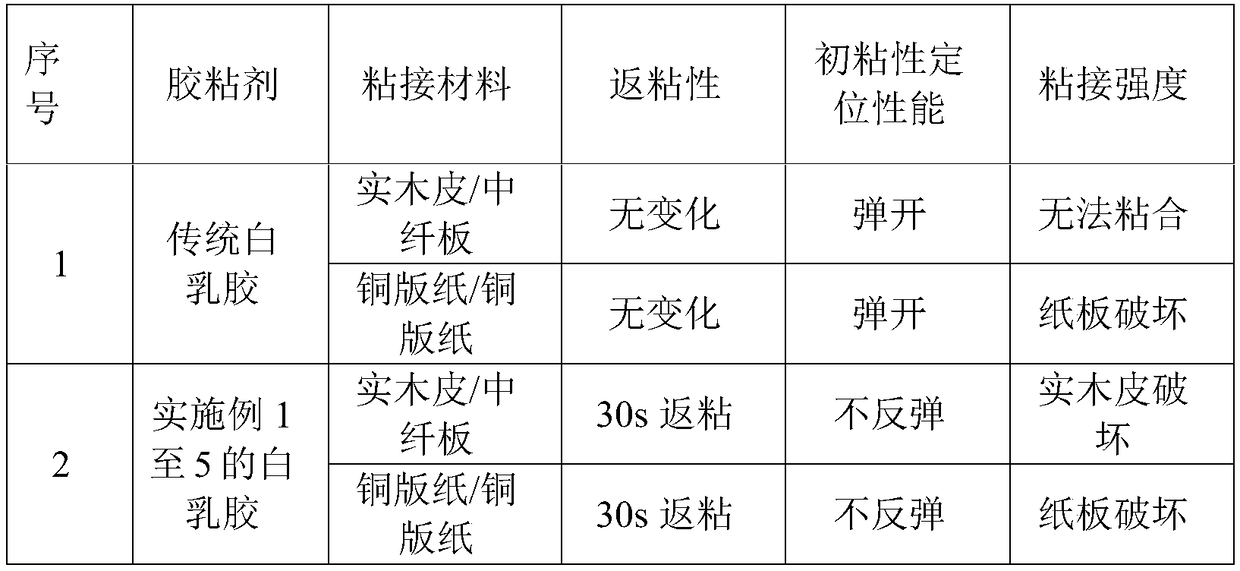

A technology for modifying water and white latex, which is applied in the direction of monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc. It can solve the problems of long cooling time, poor bonding, and failure to produce activated adhesive. Solve problems such as bonding, achieve excellent flexibility and pressure sensitivity, improve wet-state adhesive performance, and improve the effect of initial adhesive positioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of rewetting repairable modified water-based white latex of the present embodiment, the preparation method is as follows (all the following raw materials are by weight):

[0034] Step A, 25 parts of vinyl acetate, 15 parts of butyl acrylate, 6 parts of crosslinking agent and 0.02 part of chain transfer agent dodecane are mixed and stirred evenly to obtain a monomer mixture, which is set aside;

[0035] Step B, take 0.5 part of persulfate initiator, and prepare an aqueous initiator solution with a mass concentration of 2%, for subsequent use;

[0036] Step C. Add 40 parts of deionized water, 13 parts of protective colloidal polyvinyl alcohol and 0.5 parts of nonionic emulsifier into the reactor, start stirring, then raise the temperature to 92°C, fully dissolve for 2 hours, then cool down to 65°C; then, Add 1 part of buffer, 10 carboxyl group-containing polymerizable monomers, and 22% of the total mass of an initiator aqueous solution into the reactor, heat up to ...

Embodiment 2

[0048] A kind of rewetting repairable modified water-based white latex of the present embodiment, the preparation method is as follows (all the following raw materials are by weight):

[0049] Step A, 35 parts of vinyl acetate, 12 parts of butyl acrylate, 5 parts of crosslinking agent and 0.04 part of chain transfer agent dodecane are mixed and stirred evenly to obtain a monomer mixture, which is set aside;

[0050] Step B, get 1.2 parts of persulfate initiator, and prepare an aqueous initiator solution with a mass concentration of 1.5%, for subsequent use;

[0051] Step C, add 35 parts of deionized water, 15 parts of protective colloidal polyvinyl alcohol and 1.5 parts of nonionic emulsifier into the reactor, start stirring, then raise the temperature to 95°C, fully dissolve for 1.5 hours, then cool down to 70°C; then, Add 2.5 parts of buffering agent, 12 parts of carboxyl group-containing polymerizable monomers and an aqueous initiator solution accounting for 26% of the tota...

Embodiment 3

[0064] A kind of rewetting repairable modified water-based white latex of the present embodiment, the preparation method is as follows (all the following raw materials are by weight):

[0065] Step A, 40 parts of vinyl acetate, 7 parts of butyl acrylate, 10 parts of crosslinking agent and 0.03 part of chain transfer agent dodecane are mixed and stirred evenly to obtain a monomer mixture, which is set aside;

[0066] Step B, get 0.8 part of persulfate initiator, and prepare an aqueous initiator solution with a mass concentration of 3%, for subsequent use;

[0067] Step C. Add 45 parts of deionized water, 10 parts of protective colloidal polyvinyl alcohol and 2 parts of nonionic emulsifier into the reactor, start stirring, then raise the temperature to 93°C, fully dissolve for 1.3 hours, then cool down to 68°C; then, Add 0.5 parts of buffering agent, 5 carboxyl group-containing polymerizable monomers and an aqueous initiator solution accounting for 30% of the total mass to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com