Preparation method of combined phosphorus type flame-retardant acrylate pressure-sensitive adhesive

An acrylate and acrylate-based technology, which is applied in the field of flame-retardant polymer preparation, can solve the problems of flame-retardant pressure-sensitive adhesives and tape products, such as limitations and restrictions, and achieve a balance of technical bottlenecks, improved stability, and improved Effect of Flame Retardancy and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

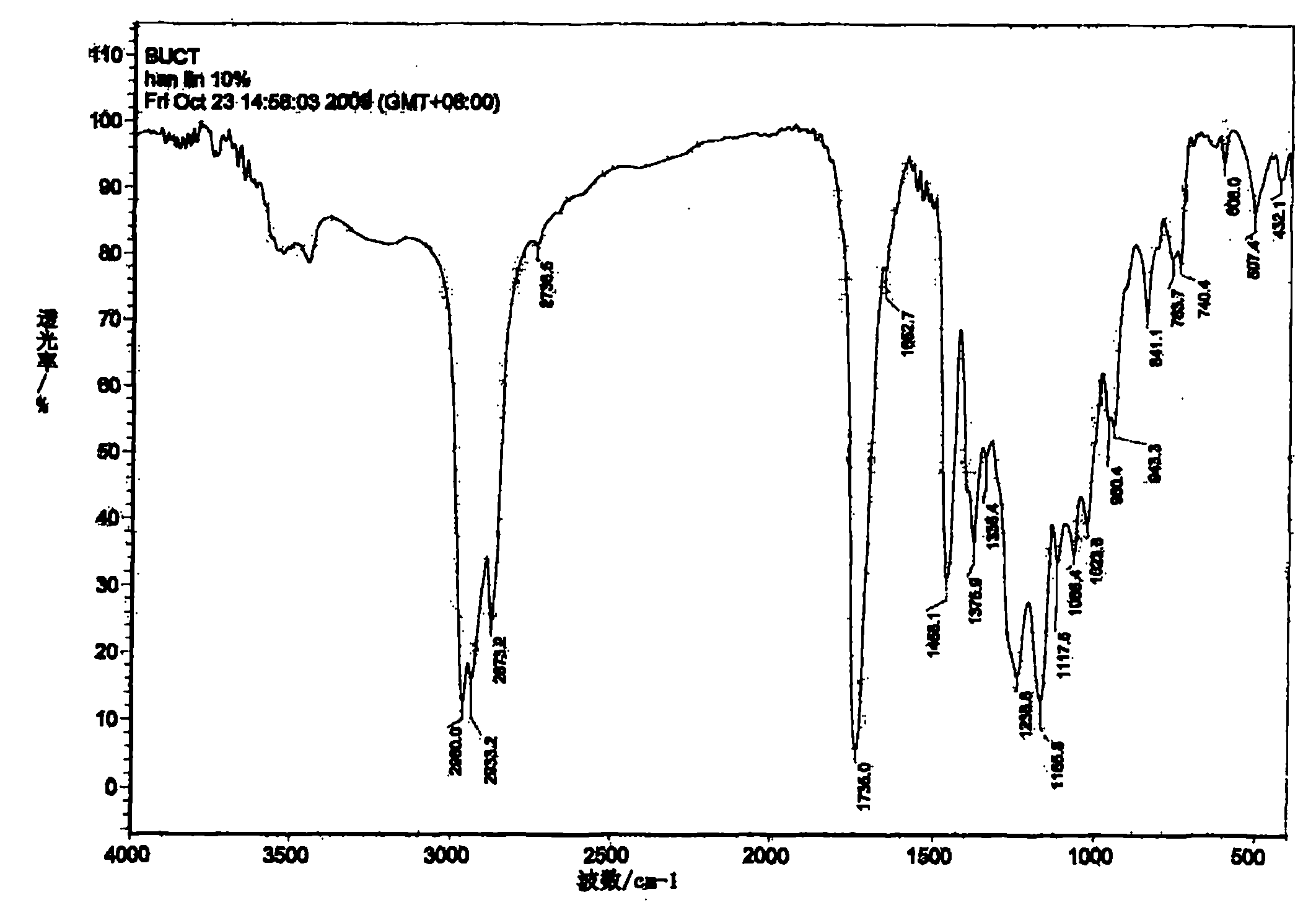

Image

Examples

Embodiment 1

[0032]1) Preparation of solvent-based binder combined with phosphorus-type flame-retardant acrylate copolymer

[0033] a: The design solid content is 40%, 40 parts by mass of acrylate, 60 parts by mass of solvent, and 0.6 part by mass of initiator. The composition and mass percentage of acrylates are: BA50%, 2-EHA12%, VAc23% , HEA4%, AA2%, and phosphorus-containing monomer PAM-300 is 9%;

[0034] b: in N 2 Under protection, 20 parts by mass of the above-mentioned acrylates were sequentially added to a mixed solvent of 7.0 parts by mass of xylene and 35.0 parts by mass of ethyl acetate, mixed uniformly and heated;

[0035] c: Add 0.4 parts by mass of initiator BPO to 7.3 parts by mass of ethyl acetate solvent and mix evenly. When the temperature rises to about 78°C for reflux condensation, add the initiator dropwise to the reaction kettle in step b, dropwise for about 0.5h Completed, constant temperature reaction for 1.0h, then lower the temperature to 75°C for 1.5h;

[0036...

Embodiment 2

[0044] 1) The preparation method of the solvent-based adhesive combined with phosphorus-type flame-retardant acrylate copolymer is as in Example 1.

[0045] 2) Preparation of flame retardant slurry

[0046] Add ethyl acetate into a 1L dispersing cylinder, turn on the high-speed dispersing machine and control the speed at 500rpm / min, then add 1.5g of pigment dispersant Texaphor 9631. After 10min, slowly add metered (300g) APP and APP oil-soluble 1181.5g of anti-sedimentation agent, and the rotation speed was adjusted to 1000rpm / min. After the feeding was completed, the dispersion was continued for 1h, and the above-mentioned prepared slurry was poured into a grinder and ground for 4h to achieve a stable effect, which was set as component 2.

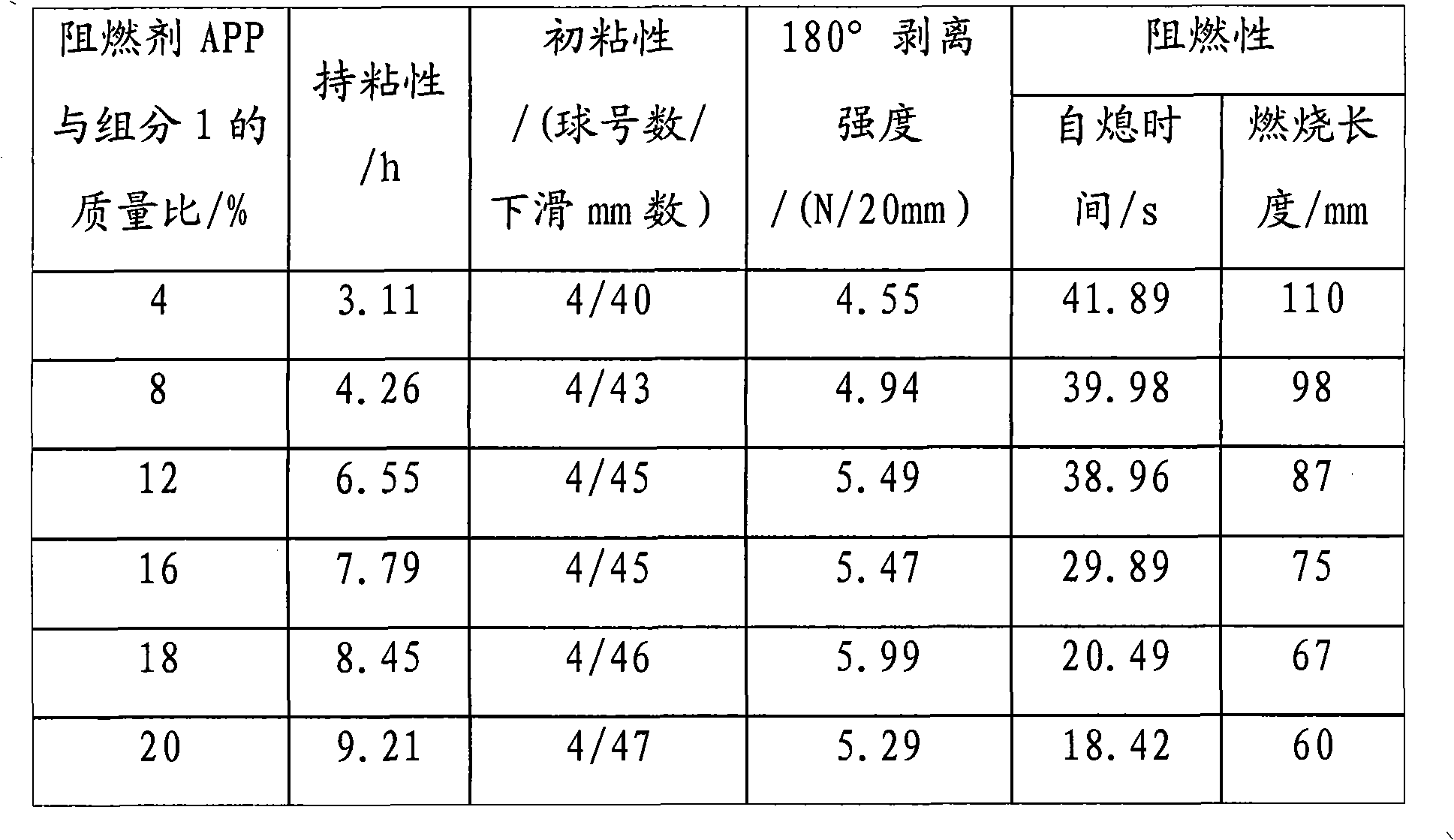

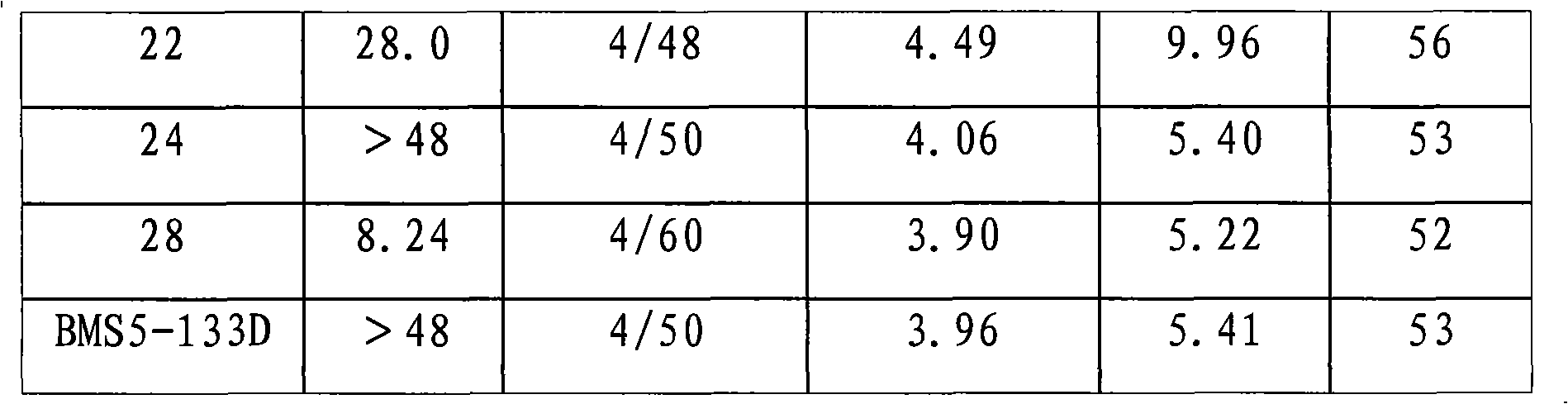

[0047] 3) Preparation of flame-retardant acrylate pressure-sensitive adhesive combined with phosphorus

[0048] Weigh Component 1 and Component 2 and mix them uniformly in proportion. When the mass ratio of APP in Component 2 to Component...

Embodiment 3

[0053] 1) Preparation of solvent-based binder combined with phosphorus-type flame-retardant acrylate copolymer

[0054] a: The design solid content is 40%, 40 parts by mass of acrylate monomer, 60 parts by mass of solvent, and 0.6 part by mass of initiator. The composition and mass percentage of acrylate are: BA41%, 2-EHA12%, VAc23 %, HEA4%, AA2%, phosphorus-containing monomer PAM-300 is 18%;

[0055] b: in N 2 Under protection, 20 parts by mass of the above-mentioned acrylate was sequentially added into a mixed solvent of 2.9 parts by mass of xylene and 27.1 parts by mass of ethyl acetate, stirred to make it evenly mixed and heated up.

[0056] c: Add 0.4 parts by mass of initiator BPO into 12.0 parts by mass of ethyl acetate solvent and stir to dissolve and mix well. When the temperature rises to reflux condensation temperature of 78°C, add the initiator dropwise to the reaction kettle of step b for about 0.5h After the dropwise addition is completed, react at constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tackiness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com