Process for preparing poly acrylate composite emulsion for pressure sensitive adhesive

A polyacrylate, pressure-sensitive adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problem of poor heat resistance, UV resistance and other properties of the coating film, and the related patents have not yet been reported. The problem of poor viscosity and other problems can achieve the effect of dimensional stability, production cost reduction, and dimensional thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] a. Preparation of seed emulsion

[0048] Ingredient parts by weight

[0049] Deionized water 100g

[0050] Nano Silica Hydrosol 4g

[0051] Emulsifier MA-80 0.09g

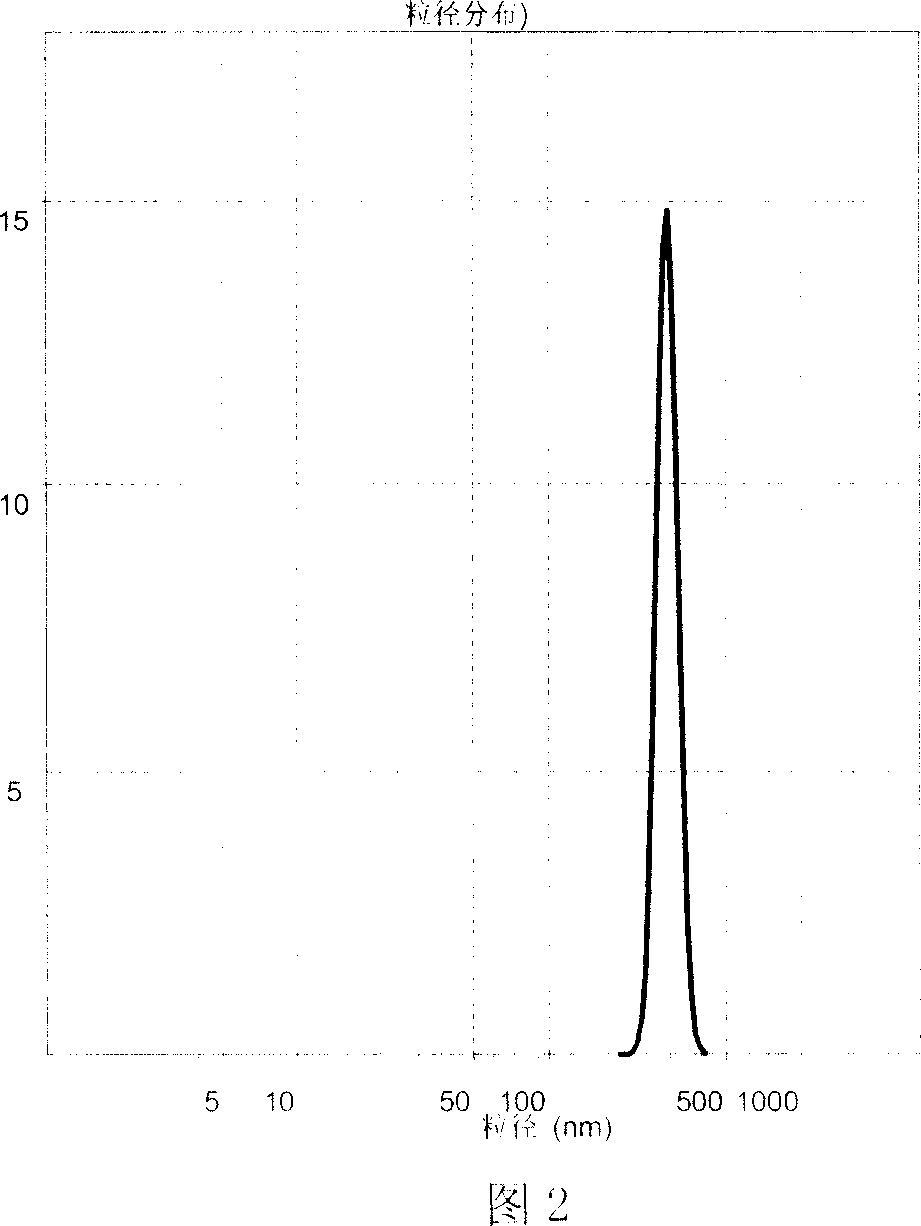

[0052] The above-mentioned nano-silica hydrosol is prepared according to the sodium silicate hydrolysis method disclosed in CN 02116759.1, its solid content is 42%-45%, the particle size is between 50-100nm, and the particle size distribution index is 0.05-0.195 Between, as shown in Figure 1, the particle diameter of this nanometer silicon dioxide is 75nm, particle size distribution coefficient 0.156, solid content is 42.53%;

[0053] In a 500mL five-neck flask, add the above-mentioned deionized water, emulsifier and nano-silica hydrosol in specified parts by weight, and stir the reaction mixture for 30 minutes to disperse it evenly to obtain a seed emulsion for subsequent use;

[0054] b. Pre-emulsification of shell monomer

[0055] Ingredient parts by mass

[0056] Butyl acrylate (hereinafter referre...

Embodiment 2~4

[0082] The ratio and amount of the pre-emulsified shell monomer components used in the step of b. shell monomer pre-emulsification in Example 1 was changed. The formula is shown in Table 1. Others were kept unchanged, and the operation was the same as in Example 1.

[0083] Example

Embodiment 5~7

[0085] The amount of emulsifier in the preparation step of a. seed emulsion of embodiment 1 is changed, and other amounts are unchanged, and the influence of the amount of emulsifier in the preparation stage of seed emulsion on the particle size of latex particles and the performance of pressure-sensitive adhesive is investigated. The formula is shown in Table 2 , operate with embodiment 1.

[0086] implement

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com