Ultrahigh-sensitivity pressure-sensitive cement-based composite material as well as preparation method and application thereof

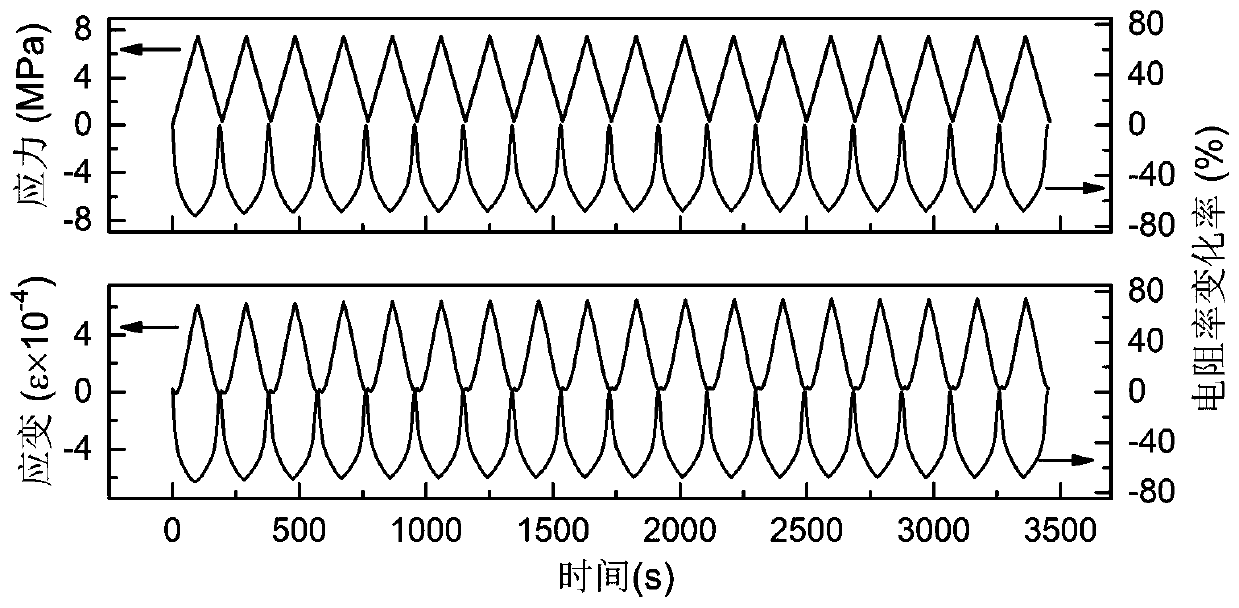

A composite material and cement-based technology, which is applied in the field of building materials, can solve the problems of affected mechanical properties and insignificant improvement of pressure-sensitive properties, and achieve improved pressure-sensitive properties, improved pressure-sensitive properties and mechanical properties, and a large resistance change rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An ultra-high-sensitivity pressure-sensitive cement-based composite material, which is composed of the following raw materials in parts by weight: 95 parts of cement, 5 parts of fly ash for growing carbon nanotubes in situ, 40 parts of water, 200 parts of sand, and 0.5 parts of water reducer share. In the fly ash with carbon nanotubes grown in situ, the mass percentage of carbon nanotubes is 0.2%.

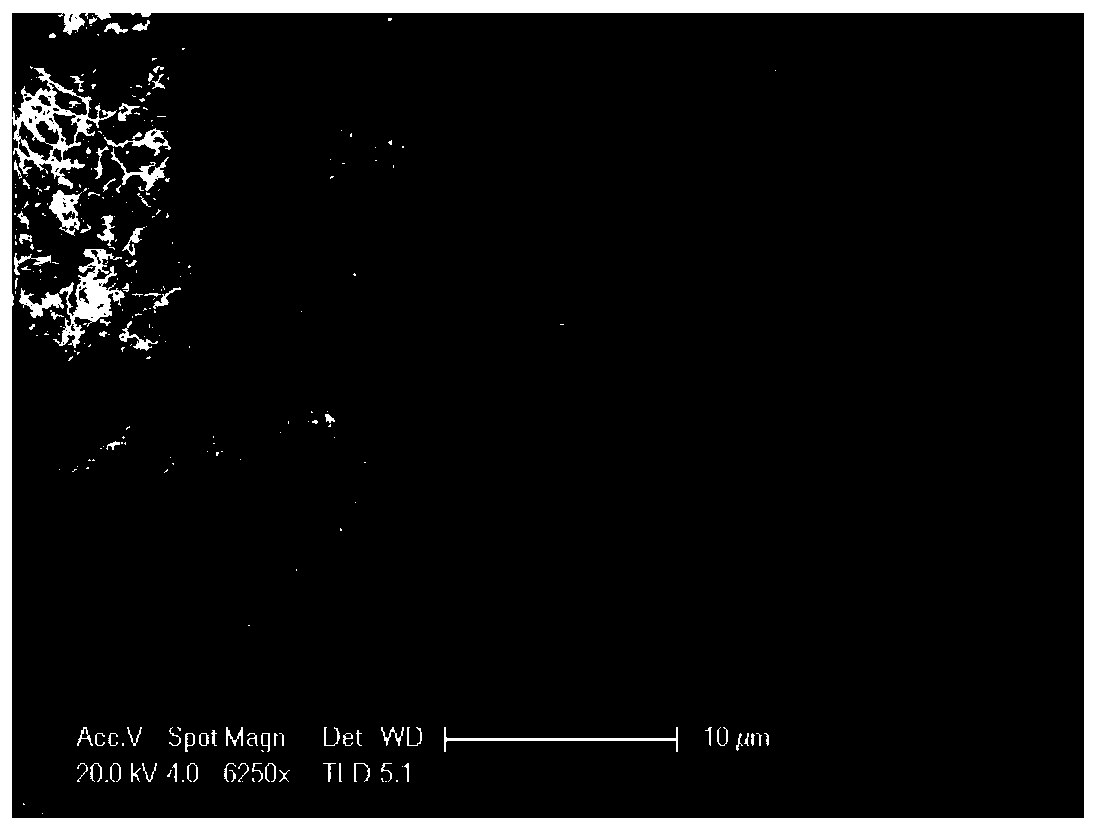

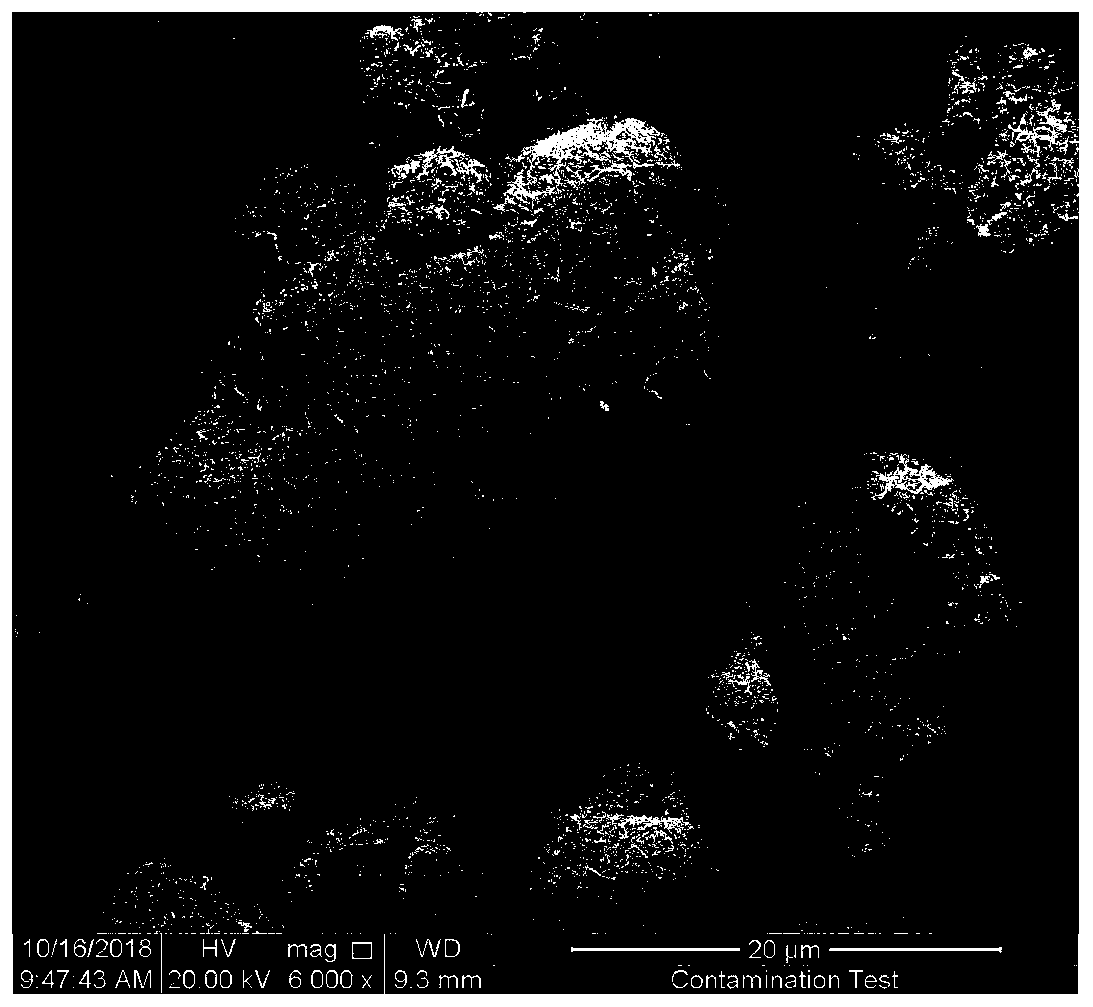

[0030] Wherein, the preparation steps of the fly ash with carbon nanotubes grown in situ on the surface are as follows:

[0031] A. Synthesis of fly ash-based conductive material

[0032] Add fly ash to dilute hydrochloric acid, then add monomer pyrrole, stir evenly, then add oxidant ammonium persulfate, continue stirring until black matter is formed, use hydrochloric acid and acetone with a concentration of 1mol / L to wash the black matter several times, and then Vacuum-dry the black substance at 50°C to constant weight to obtain a fly ash-based conductive substance, where...

Embodiment 2

[0041] An ultra-high-sensitivity pressure-sensitive cement-based composite material, which is composed of the following raw materials in parts by weight: 85 parts of cement, 15 parts of fly ash for growing carbon nanotubes in situ, 50 parts of water, 300 parts of sand, and 1 part of water reducer share. In the fly ash with carbon nanotubes grown in situ, the mass percentage of carbon nanotubes is 10%.

[0042] Wherein, the preparation steps of the fly ash with carbon nanotubes grown in situ on the surface are as follows:

[0043] A. Synthesis of fly ash-based conductive material

[0044] Add fly ash to dilute hydrochloric acid, then add monomer pyrrole, stir evenly, then add oxidant ammonium persulfate, continue stirring until black matter is formed, use hydrochloric acid and acetone with a concentration of 2mol / L to wash the black matter several times, and then Vacuum-dry the black substance at 60°C to constant weight to obtain a fly ash-based conductive substance, wherein ...

Embodiment 3

[0049] An ultra-high-sensitivity pressure-sensitive cement-based composite material is composed of the following raw materials in parts by weight: 80 parts of cement, 20 parts of fly ash for growing carbon nanotubes in situ, 60 parts of water, 300 parts of sand, and 1.5 parts of water reducer share. In the fly ash with carbon nanotubes grown in situ, the mass percentage of carbon nanotubes is 5%.

[0050] Wherein, the preparation steps of the fly ash with carbon nanotubes grown in situ on the surface are as follows:

[0051] A. Synthesis of fly ash-based conductive material

[0052] Add fly ash to dilute hydrochloric acid, then add monomer imide, stir evenly, then add oxidant ferric chloride, continue stirring until black matter is formed, use hydrochloric acid and acetone with a concentration of 7mol / L to wash the black matter several times, Then vacuum-dry the black substance at 70°C to a constant weight to obtain a fly ash-based conductive substance, wherein the molar rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com