Zinc oxide base high potential gradient pressure-sensitive ceramic material and its preparation method and uses

A varistor ceramic, zinc oxide-based technology, applied in the direction of varistors, varistor cores, etc., can solve the problems of large leakage current and small nonlinear coefficient, and achieve strong pulse impact resistance and reduce Volume and weight, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

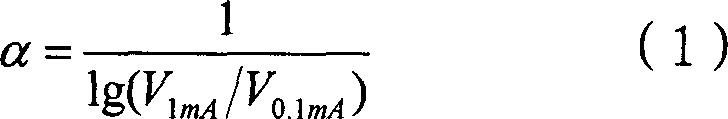

Method used

Image

Examples

Embodiment 1~16

[0033] The commercially available indirect method zinc oxide with a purity of 99.7% is used as the main component, and its average particle size is less than 1 micron. The first auxiliary component adopts commercially available chemically pure Bi 2 o 3 、Co 3 o 4 , MnCO 3 、Cr 2 o 3 、Ni 2 o 3 , SiO 2 ; The second secondary component adopts commercially available chemically pure Sb 2 o 3 ; The third subcomponent adopts commercially available analytically pure Ho 2 o 3 and Er 2 o 3 ; The fourth secondary component adopts commercially available analytical pure Al(NO 3 ) 3 9H 2 O.

[0034] The distribution ratio of each component is according to Table 1, and a total of 18 groups of samples were produced, including two groups of comparison samples. Comparative sample 1 is without Ho 2 o 3 and Er 2 o 3 The general potential gradient base formula; Comparative sample 2 is excess Ho 2 o 3 and Er 2 o 3 recipe.

[0035] Weigh the required Bi according to Table 1 ...

Embodiment 17~18

[0048] The chemical compositions of Example 9 and Example 14 were used to prepare Example 17 and Example 18 samples respectively.

[0049] The origin and purity of the raw materials used are the same as those in Examples 1-16, and the difference from Examples 1-16 lies in the manufacturing process of the additive slurry.

[0050] Weigh the required Bi according to the corresponding chemical composition 2 o 3 、Co 3 o 4 , MnCO 3 、Cr 2 o 3 、Ni 2 o 3 , SiO 2 , Sb 2 o 3 、Ho 2 o 3 、Er 2 o 3 , add pure water and mix ball milling until the average particle size is less than 1 μm, put it into an alumina crucible after drying, heat and pre-fire at 800 ° C for 2 hours, add pre-burned additives and pure water ball milling until the average particle size is less than 1 μm. Additive slurry. Subsequent production methods are the same as in Examples 1-16. The obtained electrical performance test results of the samples are listed in Table 3. Compared with the corresponding te...

Embodiment 19~24

[0052] Using the chemical composition of the 7 groups of samples in Example 6, 6 groups of samples were prepared respectively. Except that the sintering temperature is different, the manufacturing process is the same as that of Examples 17-18. Six groups of samples were made with different sintering temperatures and recorded as Examples 19-24 respectively. The test results of the samples are listed in Table 4.

[0053] From the results listed in Table 4, it can be seen that the pressure-sensitive material of the present invention can be sintered at a temperature range of 1100-1250°C. As the sintering temperature increases, the potential gradient decreases, but if the sintering temperature is too high or too low, the ability of the material to withstand the impact current will be reduced. The potential gradient of the pressure-sensitive materials obtained in Examples 19-24 is about 350-500 V / mm.

[0054] Table 1

[0055]

The first subcomponent (mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potential gradient | aaaaa | aaaaa |

| Potential gradient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com