Zinc oxide pressure-sensitive ceramic material and preparation method thereof

A varistor ceramic and zinc oxide technology, applied in the field of zinc oxide varistor ceramic materials and their preparation, can solve the problem of high residual voltage ratio and leakage current, adverse effects on the electrical properties of varistor ceramics, weak bonding between alumina and zinc oxide and other problems, to achieve the effect of eliminating the influence of pressure-sensitive performance, uniform distribution, high uniformity and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

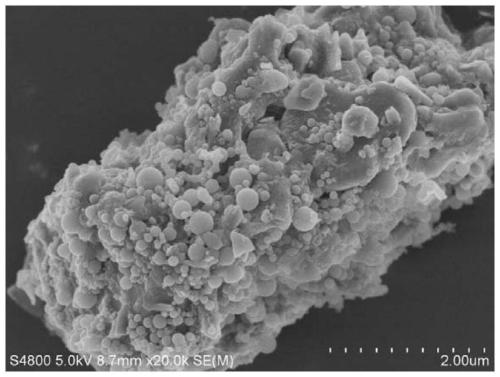

[0035] This example is used to illustrate the synthesis method of the zinc oxide and aluminum oxide composite material provided by the present invention. Zinc acetate and aluminum sulfate are used as raw materials for hydrothermal reaction, the molar ratio of zinc acetate and aluminum sulfate to acetic acid is 2:1, the molar concentration of zinc acetate is 0.1mol / L, and the molar concentration of aluminum sulfate is 0.05mol / L. Stir with a stirrer and ultrasonic to mix the solution evenly, add sodium hydroxide according to the molar ratio of sodium hydroxide to zinc acetate is 2:1, transfer the solution to the reaction kettle, and react at 150°C for 24 hours. After cooling, take out the reactor, filter out the precipitate, and wash 5 times with deionized water, then dry at 60°C, and roast at 500°C for 6 hours to obtain ZnO / Al 2 o 3 composite material. figure 1 For the prepared ZnO / Al 2 o 3 The microscopic topography of the composite material, the lamellar structure is zinc...

Embodiment 2

[0037] This example is used to illustrate the synthesis method of the zinc oxide and aluminum oxide composite material provided by the present invention. Using zinc acetate and aluminum sulfate as raw materials for hydrothermal reaction, the molar ratio of zinc acetate and aluminum sulfate to acetic acid is 4:1, the molar concentration of zinc acetate is 0.2mol / L, and the molar concentration of aluminum sulfate is 0.05mol / L. Stir with a stirrer and ultrasonic to mix the solution evenly, add sodium hydroxide according to the molar ratio of sodium hydroxide to zinc acetate is 4:1, transfer the solution to the reaction kettle, and react at 150°C for 24 hours. After cooling, take out the reactor, filter out the precipitate, and wash 5 times with deionized water, then dry at 60°C, and roast at 500°C for 6 hours to obtain ZnO / Al 2 o 3 composite material. Prepared ZnO / Al 2 o 3 The morphology of the composite material is zinc oxide with a lamellar structure, and alumina balls with...

Embodiment 3

[0039] This example is used to illustrate the synthesis method of the zinc oxide and aluminum oxide composite material provided by the present invention. Zinc acetate and aluminum sulfate are used as raw materials for hydrothermal reaction. The molar ratio of zinc acetate and aluminum sulfate to acetic acid is 6:1, the molar concentration of zinc acetate is 0.3mol / L, and the molar concentration of aluminum sulfate is 0.05mol / L. Magnetic stirring Stir and ultrasonically mix the solution evenly, add sodium hydroxide according to the molar ratio of sodium hydroxide to zinc acetate is 6:1, transfer the solution to the reaction kettle, and react at 150°C for 24 hours. After cooling, take out the reactor, filter out the precipitate, and wash 5 times with deionized water, then dry at 60°C, and roast at 500°C for 6 hours to obtain ZnO / Al 2 o 3 composite material. Prepared ZnO / Al 2 o 3 The morphology of the composite material is zinc oxide with a lamellar structure, and alumina bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com