Low-temperature sintered zinc oxide pressure-sensitive ceramic and preparation method thereof

A low-temperature sintering technology for pressure-sensitive ceramics, applied in the field of low-temperature sintered zinc oxide pressure-sensitive ceramics and its preparation, can solve problems such as high sintering temperature and occurrence of reactions, and achieve stable chemical properties, promote sintering, and good comprehensive electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

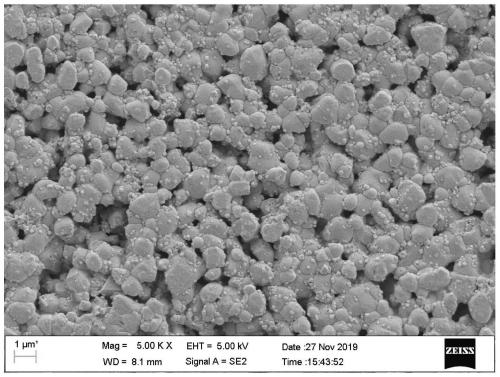

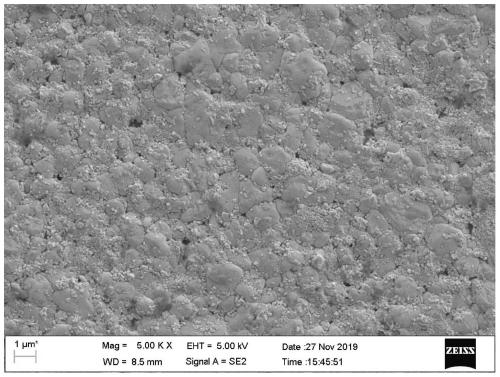

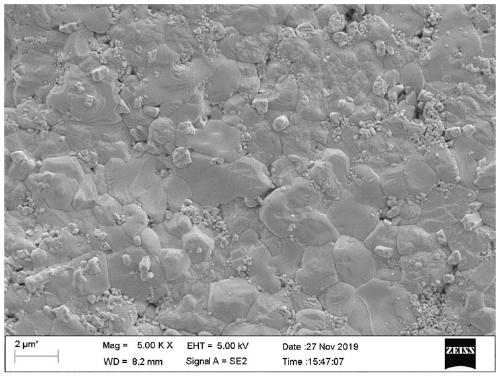

Image

Examples

Embodiment 1-4

[0033] A method for preparing low-temperature sintered zinc oxide varistor ceramics, specifically comprising the following steps:

[0034] (1) Mix zinc oxide, sintering aids and modification additives according to the proportions described in Table 1, put the mixed powder into a ball mill tank, mix it with deionized water, and ball mill it in a vertical planetary ball mill for 40 Minutes, the ratio of the powder, balls and water is 1.5:1:1. After the ball milling, put the uniformly mixed slurry in an oven to dry to obtain a dry and uniform powder.

[0035] (2) Add PVA glue (polyvinyl alcohol solution) to the powder obtained, the addition is 10wt% of ZnO, granulate and sieve, press and form, wherein the mold is a cylindrical mold with a diameter of about 14mm, and the pressure is 80MPa, pressurized The time is 3-5 seconds, and then the obtained ceramic green sheet is subjected to debinding treatment in a box furnace at a debinding temperature of 600° C., kept for 1 hour and the...

Embodiment 5

[0045] A method for preparing low-temperature sintered zinc oxide varistor ceramics, specifically comprising the following steps:

[0046] (1) Mix zinc oxide, sintering aids and modifying additives in the following proportions: ZnO and Bi 2 o 3 , Sb 2 o 3 、Co 3 o 4 , Mn 3 o 4 、Ni 2 o 3 The molar percentage is (97.3): (1): (1): (0.3): (0.2): (0.2); Cr 2 o 3 , Al(NO 3 )·9H 2 O, SiO 2 、B 4 The mass ratio of C and ZnO is (0.2):(0.0125):(0.5):(0.5):(100). After mixing, mix with deionized water and ball mill in a vertical planetary ball mill for 40 minutes. The ratio of the powder, balls and water is 1.5:1:1. After the ball milling, put the uniformly mixed slurry in an oven Dried to get a dry and uniform powder.

[0047] (2) Add PVA glue (polyvinyl alcohol solution) to the powder obtained, the addition is 10wt% of ZnO, granulate and sieve, press and form, wherein the mold is a cylindrical mold with a diameter of about 14mm, and the pressure is 80MPa, pressurized The...

Embodiment 6

[0052] A method for preparing low-temperature sintered zinc oxide varistor ceramics, specifically comprising the following steps:

[0053] (1) Mix zinc oxide, sintering aids and modifying additives in the following proportions: ZnO and Bi 2 o 3 , Sb 2 o 3 、Co 3 o 4 , MnO 2 、Ni 2 o 3 The molar percentage is (96.9): (1): (1): (0.3): (0.6): (0.2); Cr 2 o 3 , Al(NO 3 )·9H 2 O, SiO 2 、B 4 The mass ratio of C and ZnO is (0.2):(0.0125):(0.5):(0.5):(100). After mixing, mix with deionized water and ball mill in a vertical planetary ball mill for 40 minutes. The ratio of the powder, balls and water is 1.5:1:1. After the ball milling, put the uniformly mixed slurry in an oven Dried to get a dry and uniform powder.

[0054] (2) Add PVA glue (polyvinyl alcohol solution) to the powder obtained, the addition is 10wt% of ZnO, granulate and sieve, press and form, wherein the mold is a cylindrical mold with a diameter of about 14mm, and the pressure is 80MPa, pressurized The tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current | aaaaa | aaaaa |

| Voltage gradient | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com