Easy-to-produce antiexplosive voltage-dependent resister

A technology of varistors and varistors, which is applied in the directions of varistors, overvoltage protection resistors, resistor shells/packaging shells/potting, etc., which can solve the problems of optimal shell manufacturing methods and meet safety requirements. The needs of safety, avoiding pollution, and improving the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

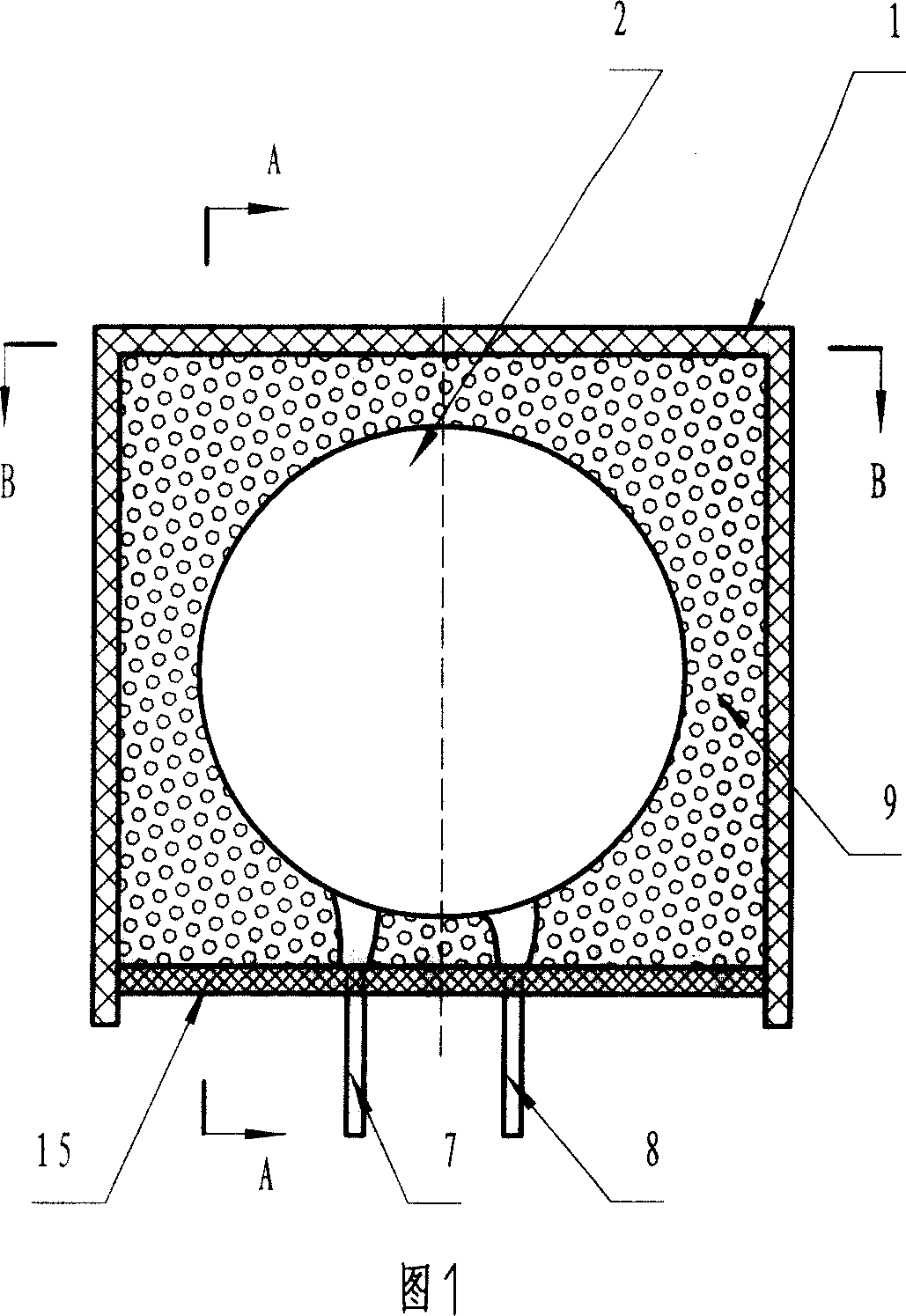

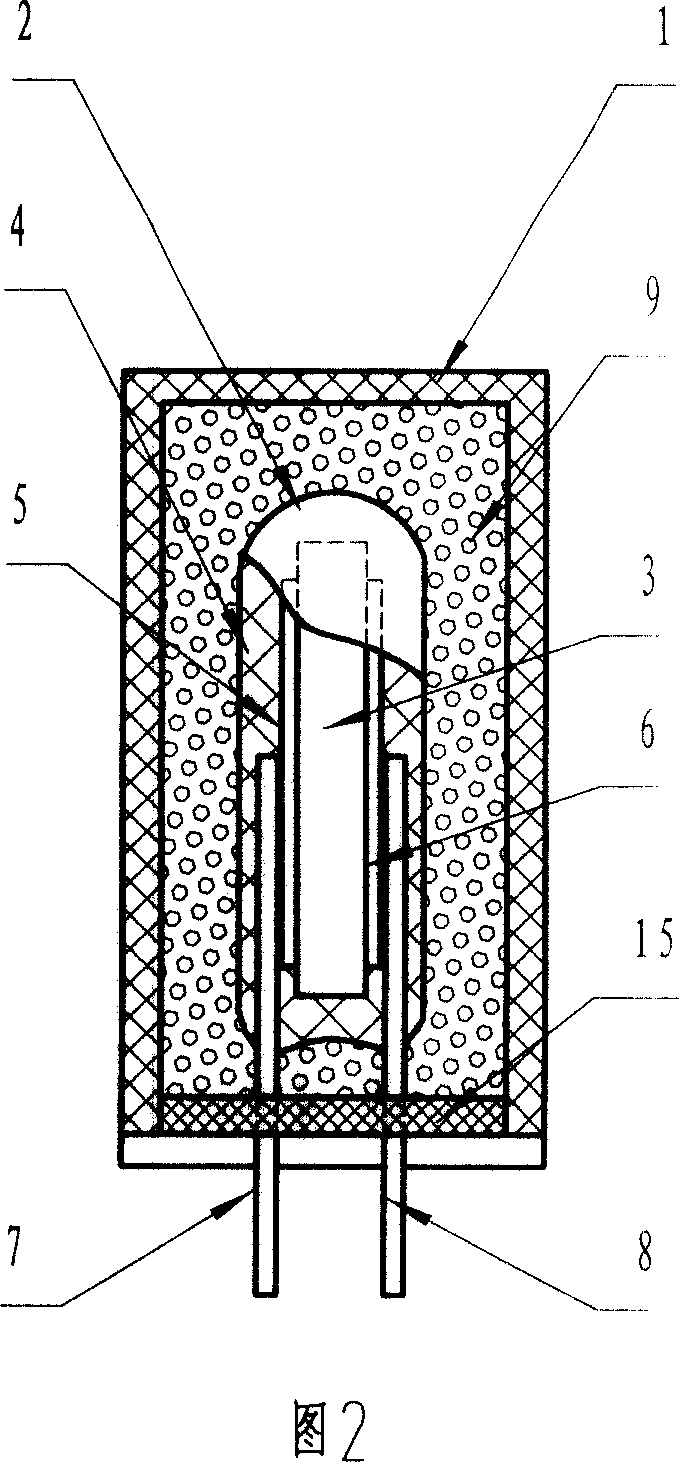

[0044] Embodiment 1: As shown in Figures 1 to 4, an explosion-proof varistor that is easy to manufacture in this embodiment has a housing 1 and a varistor main body 2 contained in the housing. The varistor The main body 2 is composed of a pressure-sensitive ceramic substrate 3 and an insulating coating layer 4 encapsulating the pressure-sensitive ceramic substrate. Two separate internal electrodes 5 and 6 are arranged on the surface of the pressure-sensitive ceramic substrate 3. The varistor main body 2 is provided with a first lead-out electrode 7 and a second lead-out electrode 8, one end of the first lead-out electrode 7 and one end of the second lead-out electrode 8 are respectively connected to two sides of the surface of the varistor ceramic substrate. The inner electrodes 5 and 6 are conductively connected, and there is a gap between the inner wall of the housing 1 and the outer wall of the piezoresistor body 2 to form a housing chamber, which is filled with insulating a...

Embodiment 2

[0046] Embodiment 2: As shown in Figures 5 to 8, the piezoresistor in this embodiment is similar to Embodiment 1, the difference is that in this embodiment, a housing cavity is provided on the housing An exhaust port communicating with the exterior of the housing. In this embodiment, the above-mentioned exhaust port sealing structure is a sealing sheet 11 (the sealing sheet 11 in this example is an aluminum foil sheet) that is pasted on the housing and seals the exhaust port 10 . Meanwhile, the insulating encapsulation layer 4 is an encapsulation layer made of silicone resin. The insulating non-combustible material layer 9 is a quartz sand layer made of quartz sand.

Embodiment 3

[0047] Embodiment 3: As shown in Figures 9-12, the piezoresistor in this embodiment is similar to Embodiment 2, the difference is that in this embodiment, the exhaust port is provided with a Exhaust port sealing structure that opens under impact. The exhaust port sealing structure is a sealing piece 12 whose periphery is fixedly connected with the inner wall of the exhaust port and seals the exhaust port. In this embodiment, an annular weak portion is preset on the housing 1, that is, an annular groove 13, and the housing part surrounded by the inner circle of the annular groove 13 constitutes the above-mentioned sealing piece 12. At the same time, the sealing The position where the blocking piece 12 is located constitutes the reserved exhaust port 10 (see FIG. 13 ). In this structure, it can be considered in a flexible way that the periphery of the sealing sheet 12 is fixedly connected with the inner wall of the exhaust port 10 and seals the exhaust port 10 . As shown in FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com