Zinc oxide resistor disc and manufacturing method thereof

A zinc oxide resistor, zinc oxide technology, applied in the direction of varistor, varistor core, etc., can solve the problem of difficulty in ensuring high gradient and high current characteristics of zinc oxide resistor, insufficient zinc oxide grain growth, Affecting the performance of zinc oxide resistors and other issues, to achieve the effect of optimizing the sintering temperature curve, inhibiting excessive grain growth, and reducing dopant volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

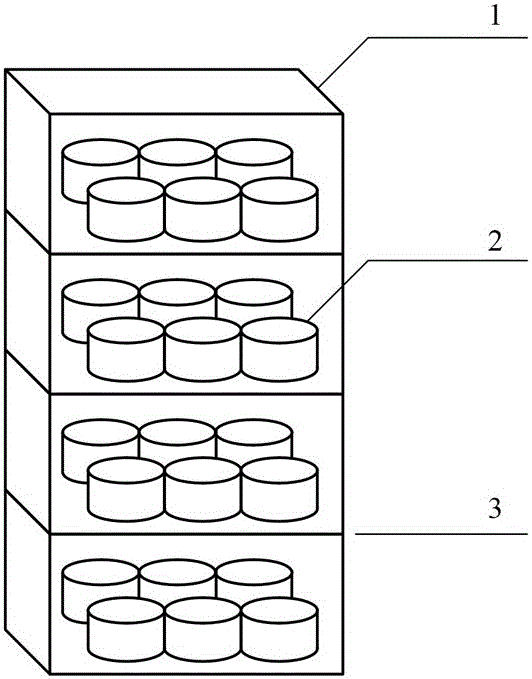

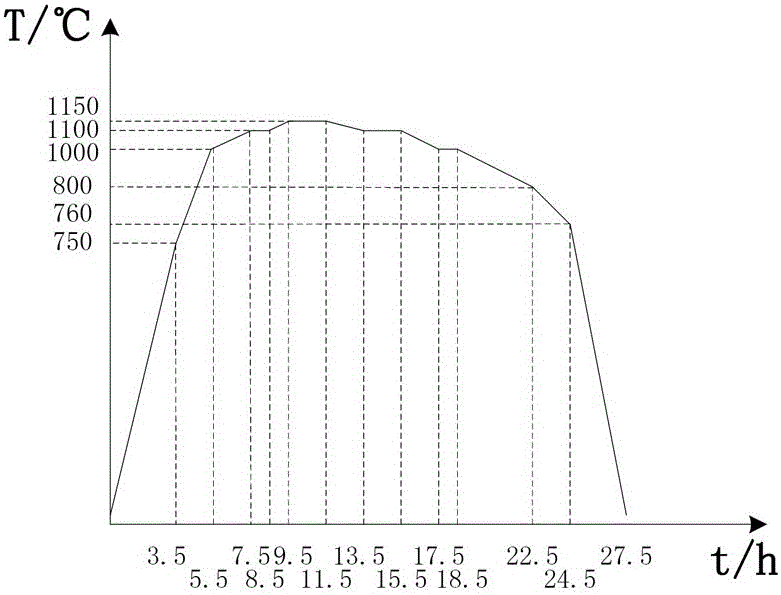

Image

Examples

Embodiment 1

[0034] A zinc oxide resistance sheet of the present invention is formed by sintering the following mole fractions of raw materials: zinc oxide: 90%, cobalt oxide: 1.1%, chromium oxide: 1.3%, silicon oxide: 1.2%, bismuth oxide: 1.4%, Nickel oxide: 0.8 mol, manganese oxide: 0.8%, antimony oxide: 1.4%, yttrium oxide 0.8% and zirconium oxide 1.2%.

[0035] A preparation method of the above-mentioned zinc oxide resistance sheet of the present embodiment, comprising the following steps:

[0036] (1) Ingredients: Weigh the following raw materials according to mole percentage: zinc oxide: 90%, cobalt oxide: 1.1%, chromium oxide: 1.3%, silicon oxide: 1.2%, bismuth oxide: 1.4%, nickel oxide: 0.8mol, oxide Manganese: 0.8%, Antimony Oxide: 1.4%, Yttrium Oxide 0.8%, and Zirconia 1.2%. A large scale balance and a precision balance are used for weighing to accurately control the proportion of each mixed material.

[0037] (2) Wet milling and granulation: add the additives described in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com