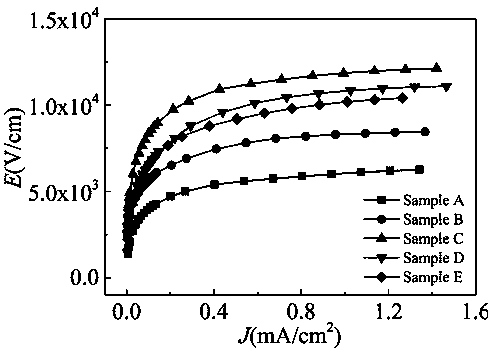

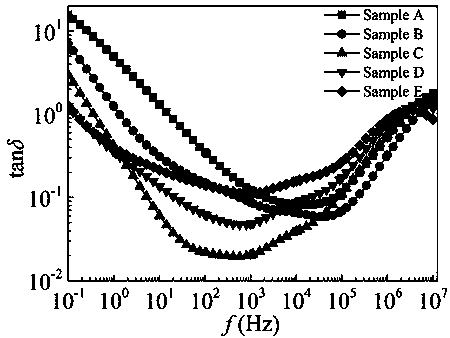

CaCu3Ti4O12 voltage-sensitive ceramic with high potential gradient and low dielectric loss and preparation method thereof

A pressure-sensitive ceramic, low-dielectric technology, applied in the field of pressure-sensitive ceramics, can solve the problems that it is difficult to meet the requirements of low loss and miniaturization of power electronic devices, low potential gradient, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

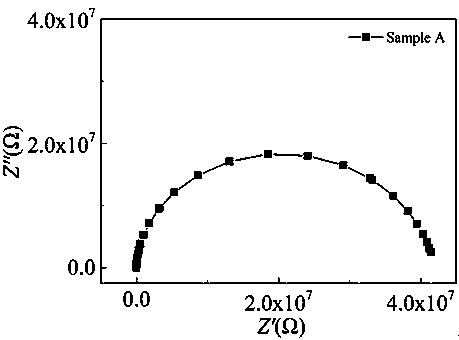

[0030] Embodiment 1: A kind of preparation high potential gradient, low dielectric loss CaCu 3 Ti 4 o 12 The method for pressure-sensitive ceramics, comprising the steps of:

[0031] S1: The high potential gradient, low dielectric loss CaCu 3 Ti 4 o 12 Varistor ceramics including CaCO 3 , CuO, TiO 2 and metal oxides; the metal oxides are ZnO and Al 2 o 3 , the CaCO 3 , CuO, TiO 2 , ZnO and Al 2 o 3 The mixed molar ratios are 1 mol, 3 mol, 4 mol, 1mol%, 1mol% respectively;

[0032] Carry out wet ball milling with alcohol as the medium after following the aforementioned ingredients;

[0033] S2: After wet ball milling for 15 hours, mix the powder at 90 o C drying 15h;

[0034] S3: Take the dried mixed powder of S2, put it into a graphite mold, and put it in a spark plasma sintering furnace under a constant pressure of 50MPa, 750 o Sintering at C temperature for 10min;

[0035] S4: Take the sample obtained in S3 and place it in a muffle furnace at 1000 o C annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com