High-performance Pr series ZnO voltage sensitive ceramic material and preparation method thereof

A high-performance technology for varistor ceramics, which is applied in the field of high-performance Pr-based ZnO varistor ceramic materials and its preparation. It can solve the problems of preparation of Pr-based ZnO varistor ceramics that have not been reported, hinder large-scale application and commercialization, and have high nonlinear coefficients. problems, to achieve the effect of large nonlinear coefficient, less types and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of nanocomposite ZnO powder

[0027] (1) Prepare Pr(NO 3 ) 3 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 , Y(NO 3 ) 3 solution, according to 0.5% Pr 6 o 11 , 0.5% MnO, 1% CoO, 0.5% Y 2 o 3 (converted into oxide) proportioning mixing and stirring evenly;

[0028] (2) Prepare a mixed solution of ethylene glycol and ethanol at a volume ratio of 2:1, add the mixed solution obtained in step (1), and stir for more than 1 hour. Add 97.5% nano-ZnO particle size (50nm~100nm), ultrasonically disperse at 40°C for 4 hours, and stir at 80°C for 1 hour to form a suspension;

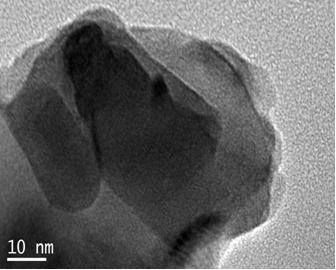

[0029] (3) Dry the suspension obtained in step (2) at 150°C for 8 hours, and calcinate at 450°C for 6 hours to obtain ZnO-coated powder (see e.g. figure 1 );

[0030] (4) After the ZnO-coated powder was calcined at 750° C. for 2 hours, the nanocomposite ZnO powder was obtained.

[0031] 2. Preparation of Pr-based ZnO varistor ceramics

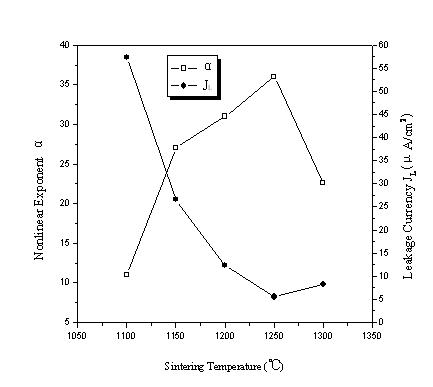

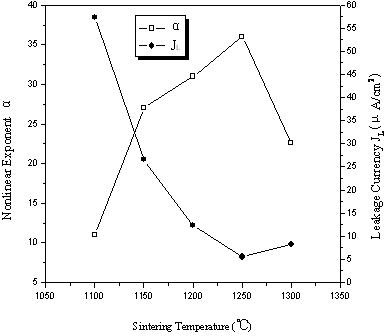

[0032] (1) Adding mass fraction to the nanocomposite ZnO powd...

Embodiment 2

[0037] In this example, when the nanocomposite ZnO powder is prepared by the coating method, the molar ratio of each component (by oxide) is 0.5% Pr 6 o 11 , 0.8% MnO, 1% CoO, 0.7% Y 2 o 3 , 97% nano ZnO. The above materials were prepared into high-performance Pr-based ZnO varistor ceramics using the same process steps as in Example 1, the difference being that the sintering temperature of the ceramics was 1200°C.

[0038] The performance index of the ceramic is: varistor voltage V 1mA 830V / mm, nonlinear coefficient α is 28, leakage current J leak It is 4.4μA (measured at 83% varistor voltage).

Embodiment 3

[0039]Example 3 In this example, when the nanocomposite ZnO powder is prepared by the coating method, the molar ratio of each component (by oxide) is 0.5% Pr 6 o 11 , 1% MnO, 1% CoO, 1% Y 2 o 3 , 96.5% nano ZnO. The above materials were prepared into high-performance Pr-based ZnO varistor ceramics using the same process steps as in Example 1, the difference being that the sintering temperature of the ceramics was 1200°C.

[0040] The performance index of the ceramic is: varistor voltage V 1mA 790V / mm, nonlinear coefficient α is 32, leakage current J leak It is 5.2μA (measured at 83% varistor voltage).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com