Horizontally arranged cathode vacuum electroosmosis sludge dehydration device and method

A technology of dewatering device and flat cathode, which is applied in dewatering/drying/concentrating sludge treatment, polluted waterway/lake/pond/river treatment, etc., can solve the problems of high sludge moisture content, wide vertical cracks, large deformation, etc. , to achieve the effect of reducing cost, reducing resistance increase, and reducing engineering quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

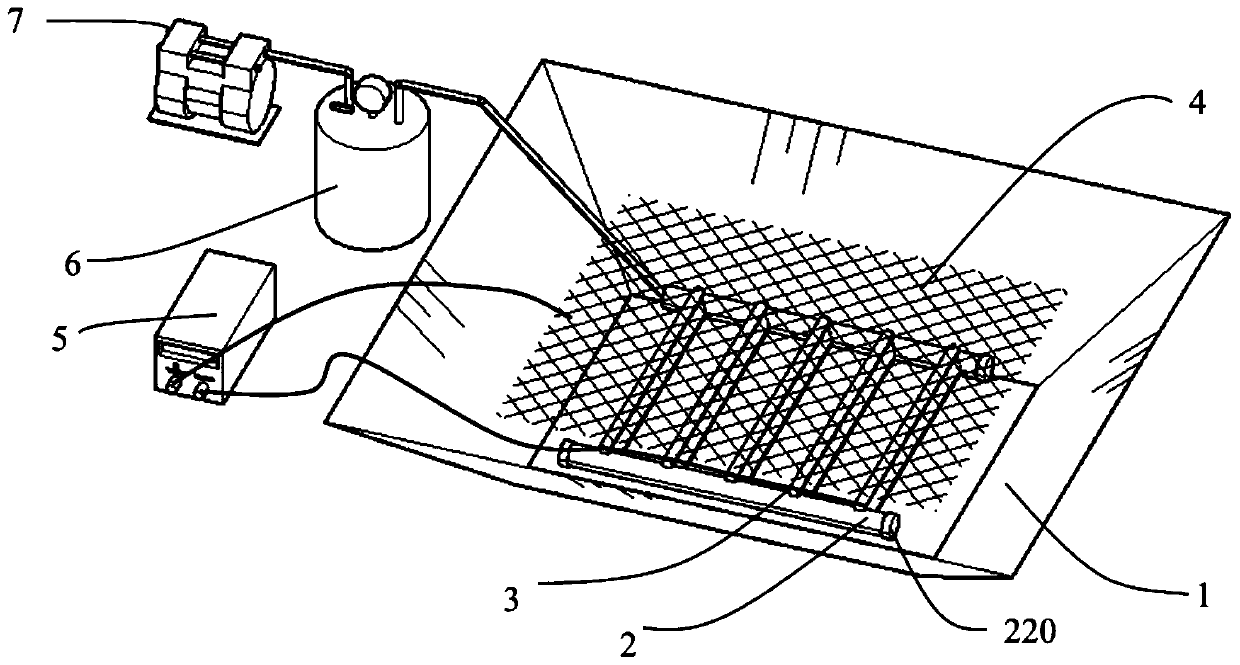

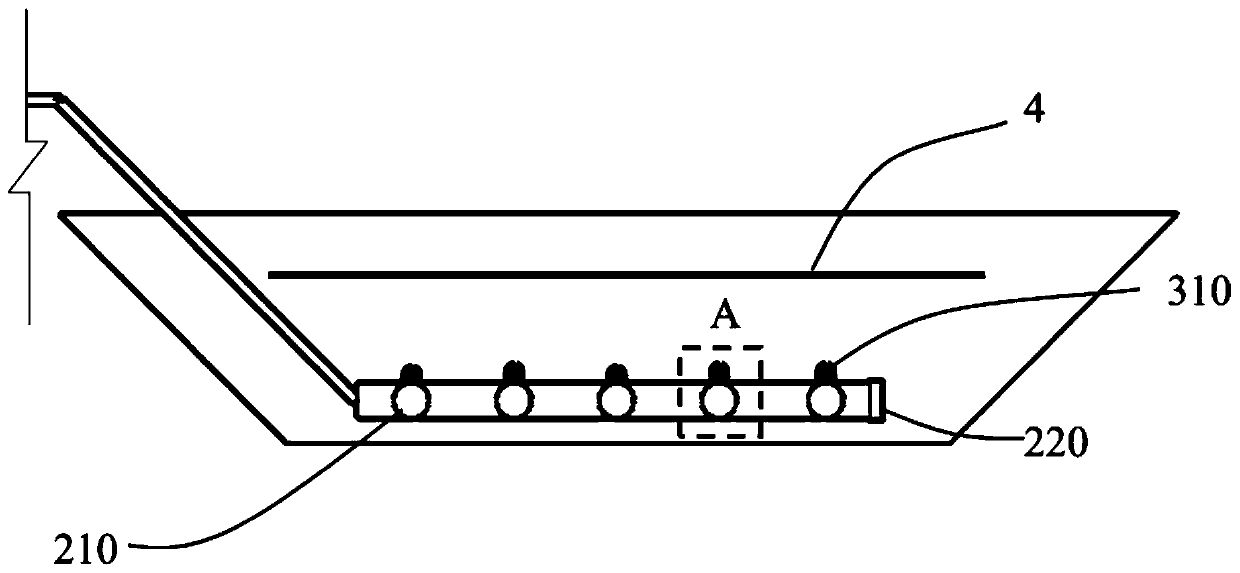

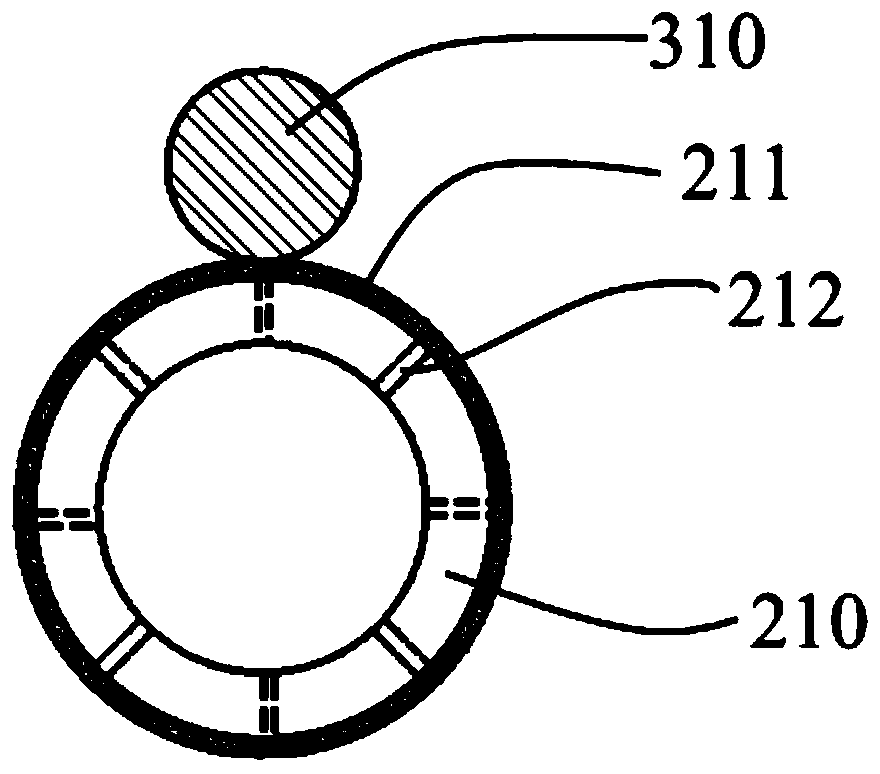

[0033] A horizontally arranged cathodic vacuum electroosmosis sludge dehydration device, comprising a sludge tank 1, a filter pipe network 2 is laid horizontally in the sludge tank 1, a flat cathode 3 is laid horizontally above the filter pipe network 2, and a flat cathode 3 and the filter pipe network 2 are all buried in the sludge in the sludge pool 1, and the upper surface of the sludge in the sludge pool 1 is provided with a plane anode 4, and the plane anode 4 and the plane cathode 3 are parallel and arranged correspondingly, and the plane anode 4 It is electrically connected with the positive pole of the DC power supply 5, and the plane cathode 3 is electrically connected with the negative pole of the DC power supply 5; a water-gas separation device 6 is arranged on the side of the sludge tank 1, and one end of the water-gas separation device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com