Zinc-oxide piezoresistor raw material, preparation method thereof and piezoresistor

A varistor and zinc oxide technology, applied in the field of varistor materials, its preparation, raw material of zinc oxide varistors, can solve the problems of carcinogenicity, affecting the function of enzymes and organs, and failing to meet the needs of applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

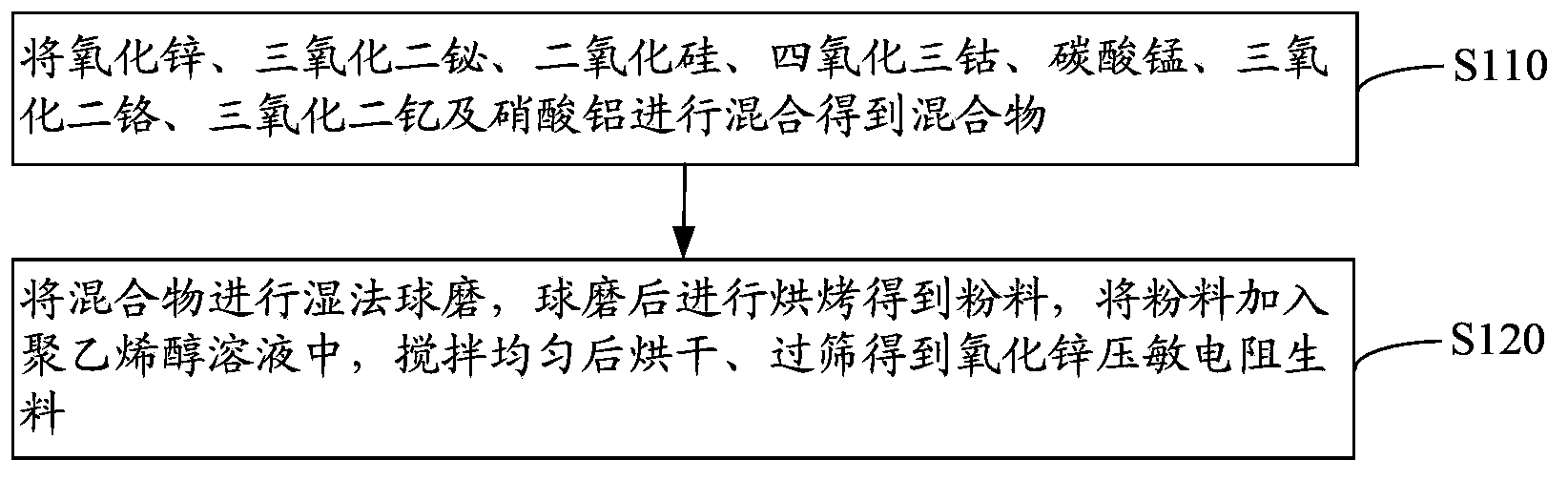

[0040] see figure 1 , the preparation method of zinc oxide varistor raw material of an embodiment, comprises following step S110 to step S120:

[0041] Step S110: mixing zinc oxide, bismuth trioxide, silicon dioxide, cobalt tetroxide, manganese carbonate, chromium trioxide, yttrium trioxide and aluminum nitrate to obtain a mixture.

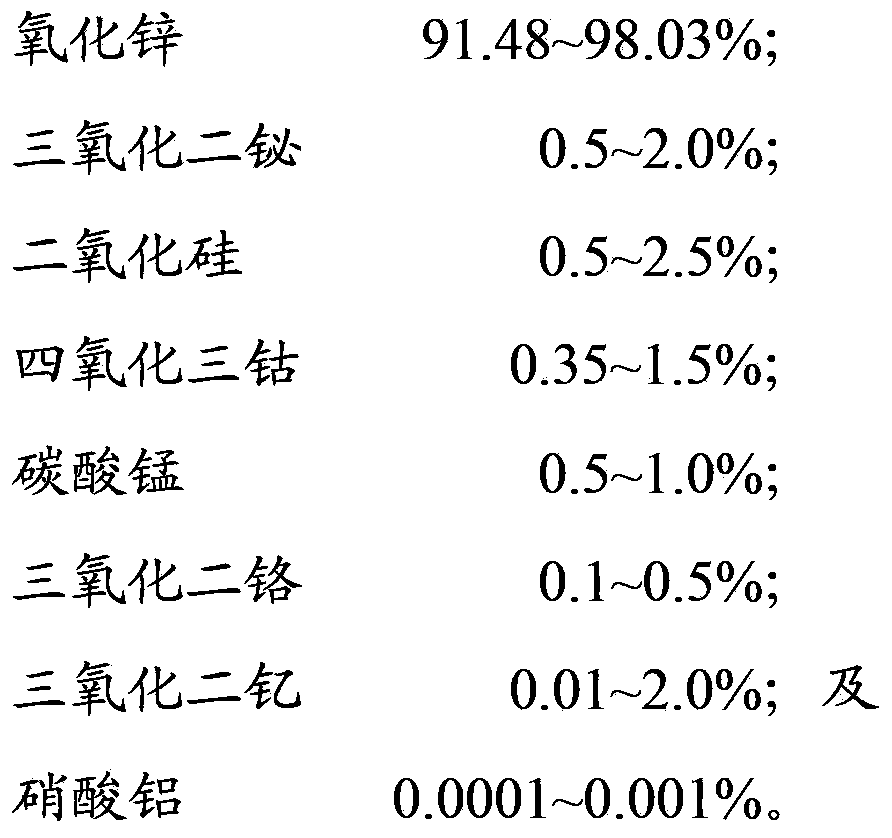

[0042] In the above mixture, zinc oxide accounts for 91.48-98.03%, bismuth trioxide accounts for 0.5-2.0%, silicon dioxide accounts for 0.5-2.5%, tricobalt oxide accounts for 0.35-1.5%, and manganese carbonate accounts for 0.5-1.0% by mole percentage. ; Chromium trioxide accounts for 0.1-0.5%, diyttrium trioxide accounts for 0.01-2.0%, and aluminum nitrate accounts for 0.0001-0.001%.

[0043] Among them, zinc oxide, bismuth trioxide, silicon dioxide, cobalt tetroxide, manganese carbonate, chromium trioxide, yttrium trioxide and aluminum nitrate are produced by domestic manufacturers.

[0044] Step S120: The mixture is subjected to wet ball milli...

Embodiment 1

[0058] Preparation of piezoresistors

[0059] 1. Preparation of zinc oxide varistor raw materials

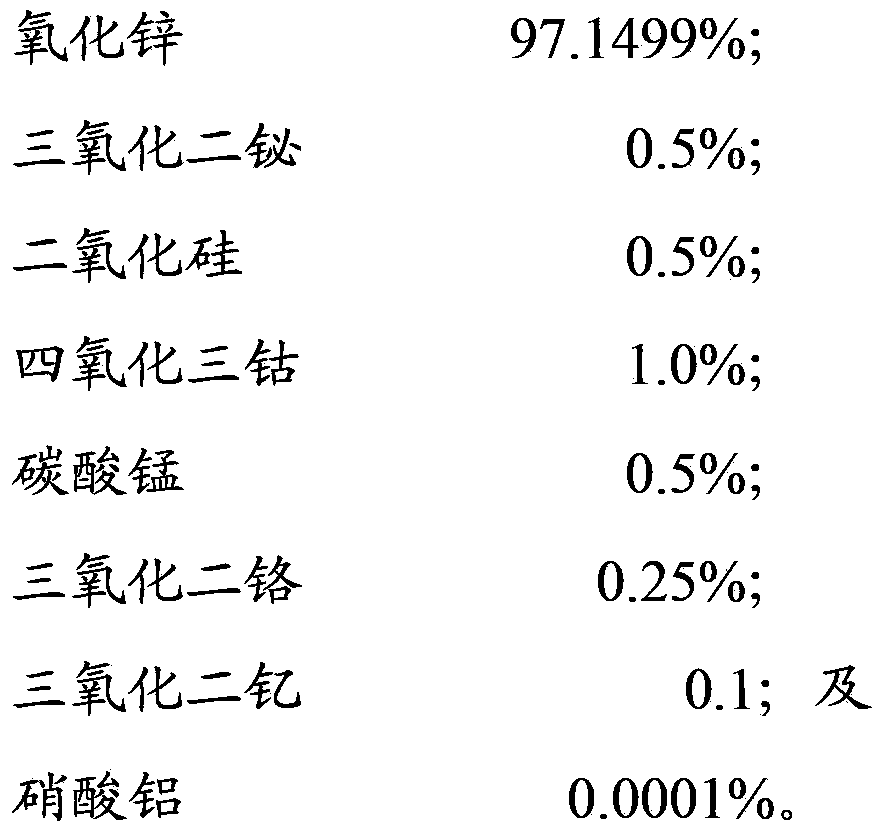

[0060] (1) Mix zinc oxide, bismuth trioxide, silicon dioxide, tricobalt tetroxide, manganese carbonate, chromium trioxide, yttrium trioxide and aluminum nitrate to obtain a 400g mixture. In the mixture, by mole percentage: oxide Zinc accounted for 97.1499%, bismuth trioxide accounted for 0.5%, silicon dioxide accounted for 0.5%, tricobalt tetroxide accounted for 1.0%, manganese carbonate accounted for 0.5%; 0.0001%;

[0061] (2) Pour the above mixture into a polyurethane ball mill tank with 800g of zirconium balls with a diameter of 7.5mm, add 400g of deionized water, seal it, and wet grind it on a planetary ball mill for 4 hours at a speed of 400r / min. Pour the material into a stainless steel tray, put it in an oven at 150°C and bake for 3 hours to obtain a powder, add the powder to 48g of PVA solution with a concentration of 5%, stir evenly, and then put it in an oven at 150...

Embodiment 2

[0065] Preparation of piezoresistors

[0066] 1. Preparation of zinc oxide varistor raw material

[0067] (1) Mix zinc oxide, bismuth trioxide, silicon dioxide, tricobalt tetroxide, manganese carbonate, chromium trioxide, yttrium trioxide and aluminum nitrate to obtain a 400g mixture. In the mixture, by mole percentage: oxide Zinc accounted for 96.5499%, bismuth trioxide accounted for 0.5%, silicon dioxide accounted for 1.0%, tricobalt tetroxide accounted for 1.0%, manganese carbonate accounted for 0.5%; 0.0001%;

[0068] (2) Pour the above mixture into a polyurethane ball mill tank with 800g of zirconium balls with a diameter of 7.5mm, add 400g of deionized water, seal it, and wet grind it on a planetary ball mill for 5 hours at a speed of 500r / min. Pour the material into a stainless steel pan, put it in an oven at 200°C and bake it for 4 hours to obtain a powder. Add the powder to 48g of PVA solution with a concentration of 5%, stir evenly, and then put it in an oven at 18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com