Heat preservation device for microwave sintering and microwave sintering method of zinc oxide pressure-sensitive ceramic

A technology of microwave sintering and heat preservation devices, which is applied to thermometers and piezoresistors that use electrical devices, electric/magnetic elements that are directly sensitive to heat, etc., can solve the problem that the infrared thermometer has too large a spot and cannot achieve overall heating, Problems such as ceramic sheet deformation and color can be shortened to shorten the sintering time, improve the performance of nonlinear volt-ampere characteristics and voltage gradient, and shorten the sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

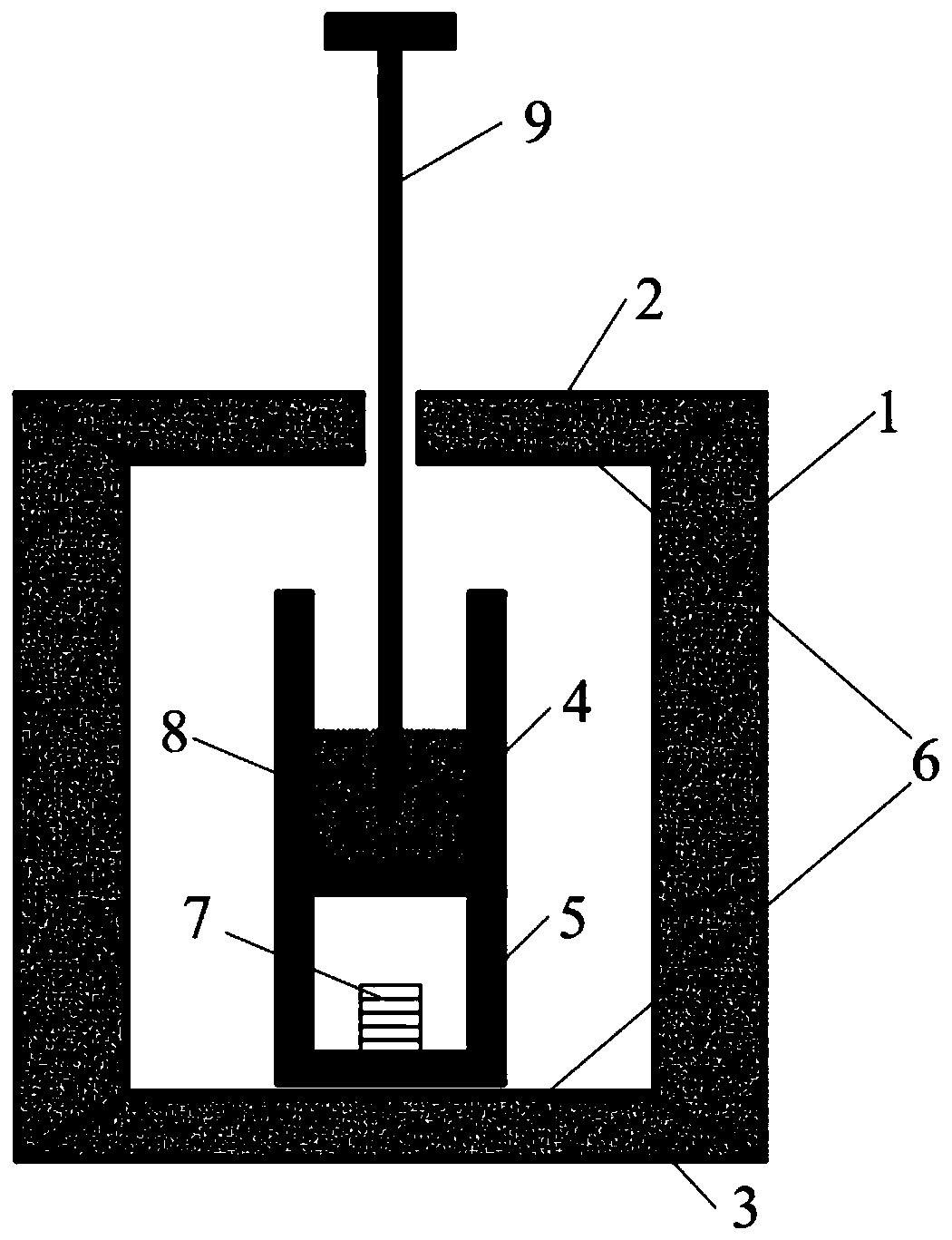

[0047] Embodiment 1 provides a kind of insulation device (such as figure 1 shown) and a temperature measurement method for microwave sintering. The device is composed of a cylindrical box body 1, an upper end cover 2, a lower end cover 3, a tall crucible 4 and a short crucible 5. The cylindrical box body 1 is made of polycrystalline mullite refractory porous material; the inner surfaces of the two end caps are each coated with a wave-absorbing silicon carbide coating 6, wherein the upper end cap 2 has a small hole ; The two crucibles are fused silica crucibles, which are stacked up and down, and the short crucible 5 is placed below. The green ceramic sheet 7 is placed in the crucible with a relatively short height, and the powder 8 for pressing the green ceramic sheet is placed in the high crucible 4, and the powder 8 is used for pressing the green ceramic sheet The powder used for the pressed ceramic sheet green body is a mixture (zinc oxide, bismuth oxide, tricobalt oxide,...

Embodiment 2

[0050] This embodiment provides a method for microwave sintering zinc oxide varistor ceramics, comprising the following steps:

[0051] (1) Zinc oxide pressure-sensitive ceramic slurry is prepared, and the parts by weight of each raw material are composed as follows:

[0052] 100 parts of zinc oxide, 4 parts of bismuth oxide, 2 parts of tricobalt tetroxide, 0.75 parts of manganese carbonate, 0.2 part of antimony oxide, 0.5 part of nickel trioxide, 0.55 part of titanium dioxide, 5 parts of aluminum nitrate nonahydrate solution, 5 parts of dispersant, and the The above materials are mixed to obtain mixed powder; the zinc oxide is manufactured by an indirect method, the average particle diameter is controlled at 0.45-0.55 μm, and the particle shape is nearly spherical; the aluminum nitrate nonahydrate solution is according to the aluminum nitrate nonahydrate: water=1 : Prepared with a mass ratio of 250;

[0053] (2) Put the mixed powder in step (1) into a ball mill tank and add ...

Embodiment 3

[0062] This embodiment provides a method for microwave sintering zinc oxide varistor ceramics, comprising the following steps:

[0063] (1) Zinc oxide pressure-sensitive ceramic slurry is prepared, and the parts by weight of each raw material are composed as follows:

[0064] 100 parts of zinc oxide, 4 parts of bismuth oxide, 2 parts of tricobalt tetroxide, 0.75 parts of manganese carbonate, 0.2 part of antimony oxide, 0.5 part of nickel trioxide, 0.8 part of titanium dioxide, 5 parts of aluminum nitrate nonahydrate solution, 5 parts of dispersant, the above The materials are mixed to obtain a mixed powder; the zinc oxide is produced by an indirect method, the average particle size is controlled at 0.45-0.55 μm, and the particle shape is nearly spherical; the aluminum nitrate nonahydrate solution follows the aluminum nitrate nonahydrate: water=1: 250 mass ratio preparation;

[0065] (2) Put the mixed powder in step (1) into a ball mill tank and add an appropriate amount of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com