Preparation method of zinc oxide varistor sheet

A varistor, zinc oxide technology, applied in varistor, varistor core, resistor manufacturing and other directions, can solve the problems of high power consumption, high energy consumption, long time consumption, etc., to reduce energy consumption, The effect of increasing the voltage gradient and contributing to grain boundary diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

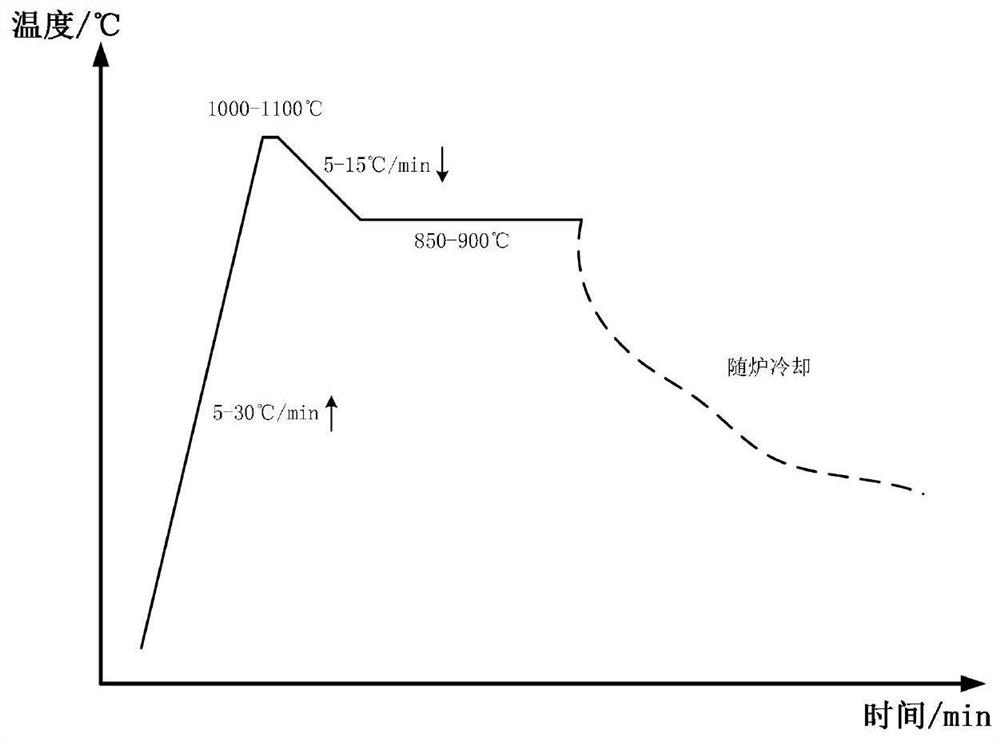

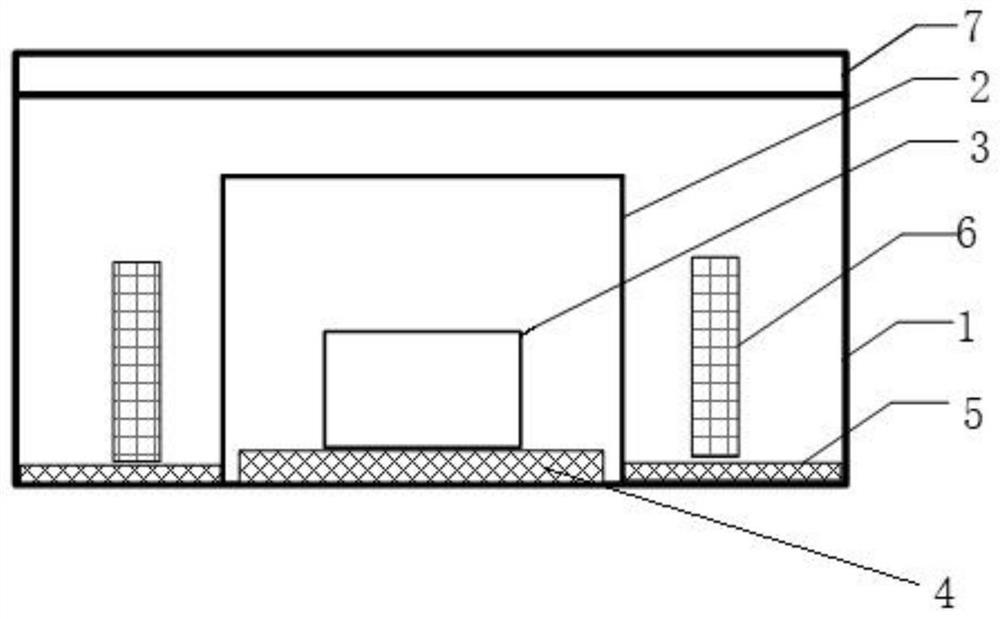

[0026] This specific embodiment proposes a preparation method of a zinc oxide varistor sheet, comprising the following steps:

[0027] 1) Preparation of mixed slurry: take zinc oxide as the main material and auxiliary materials including bismuth oxide as raw materials, weigh the raw materials in proportion, pour in deionized water 1.0-1.5 times the weight of the powder, and add polyacrylic acid ammonia dispersant , in the sand mill, set the rotating speed to 1500-2500r / min, grind at high speed for 1-2h, and obtain the mixed slurry. The raw materials in molar percentage include zinc oxide: 93.5-95.5%, bismuth oxide: 1.0-2.5%, antimony oxide: 1-1.5%, cobalt oxide: 0.5-1.0%, manganese oxide: 0.45-1.0%, dioxide Silicon: 0.5-1.5%, boron trioxide: 0.15-0.4%, aluminum nitrate: 0.05-0.15%.

[0028] 2) Preparation of green body: add polyvinyl alcohol binder to the mixed slurry, spray dry, pass the dried powder through an 80-100 mesh sieve, and press it to an initial density of 3.10-3....

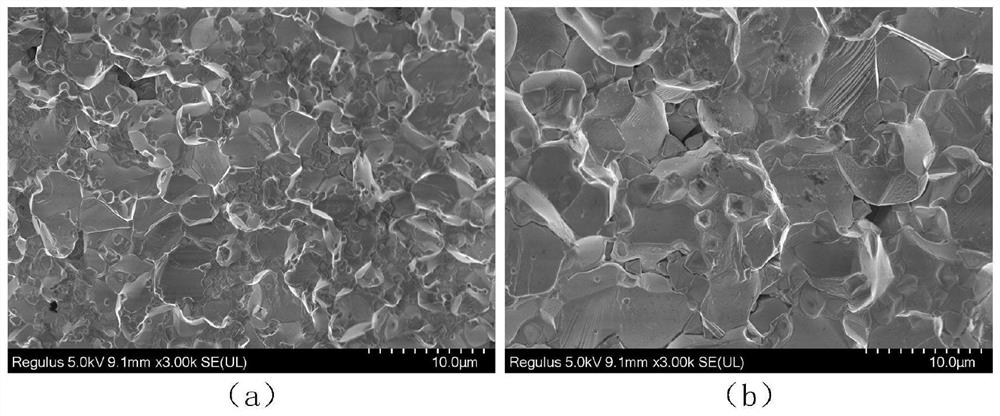

Embodiment 1

[0038] The present embodiment proposes a method for preparing a zinc oxide varistor sheet, comprising the following steps:

[0039] (1) Preparation of raw materials: prepare according to the molar percentage of raw materials, including zinc oxide main material and various dopants, as follows: zinc oxide: 94.61%, bismuth oxide: 1.5%, antimony oxide: 1.0%, cobalt oxide: 0.8%, manganese oxide: 0.75%, nickel oxide: 1.0%, boron trioxide 0.24%, aluminum nitrate: 0.10%;

[0040] (2) Green body preparation: weigh the raw materials in proportion, pour in deionized water 1.5 times the weight of the powder, add polyacrylic acid ammonia dispersant, set the rotational speed to 2000r / min in the sand mill, and grind at high speed. 1.5h, the mixed slurry was obtained, polyvinyl alcohol binder was added, spray-dried, the dried powder was passed through an 80-mesh sieve, and pressed to an initial density of 3.20g / cm 3 The green zinc oxide varistor sheet;

[0041] (3) Debinding of the green bo...

Embodiment 2

[0047] The present embodiment proposes a method for preparing a zinc oxide varistor sheet, comprising the following steps:

[0048] (1) Preparation of raw materials: prepare according to the molar percentage of raw materials, including zinc oxide main material and various dopants, as follows: zinc oxide: 94.86%, bismuth oxide: 1.5%, antimony oxide: 0.8%, cobalt oxide: 1.0%, manganese oxide: 0.5%, nickel oxide: 1.0%, boron trioxide 0.24%, aluminum nitrate: 0.10%;

[0049] (2) Green body preparation: weigh the raw materials in proportion, pour in deionized water 1.5 times the weight of the powder, add polyacrylic acid ammonia dispersant, set the rotational speed to 2000r / min in the sand mill, and grind at high speed. 1.5h, the mixed slurry was obtained, polyvinyl alcohol binder was added, spray-dried, the dried powder was passed through an 80-mesh sieve, and pressed to an initial density of 3.20g / cm 3 The green zinc oxide varistor sheet;

[0050] (3) Debinding of the green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com