Medium voltage varistor and preparation method thereof

A varistor and resistance technology, applied in the field of medium voltage varistor and its preparation, can solve the problems of increased difficulty, high height, volume and weight, inconvenient transportation and installation, etc., and achieve the effect of high voltage gradient and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

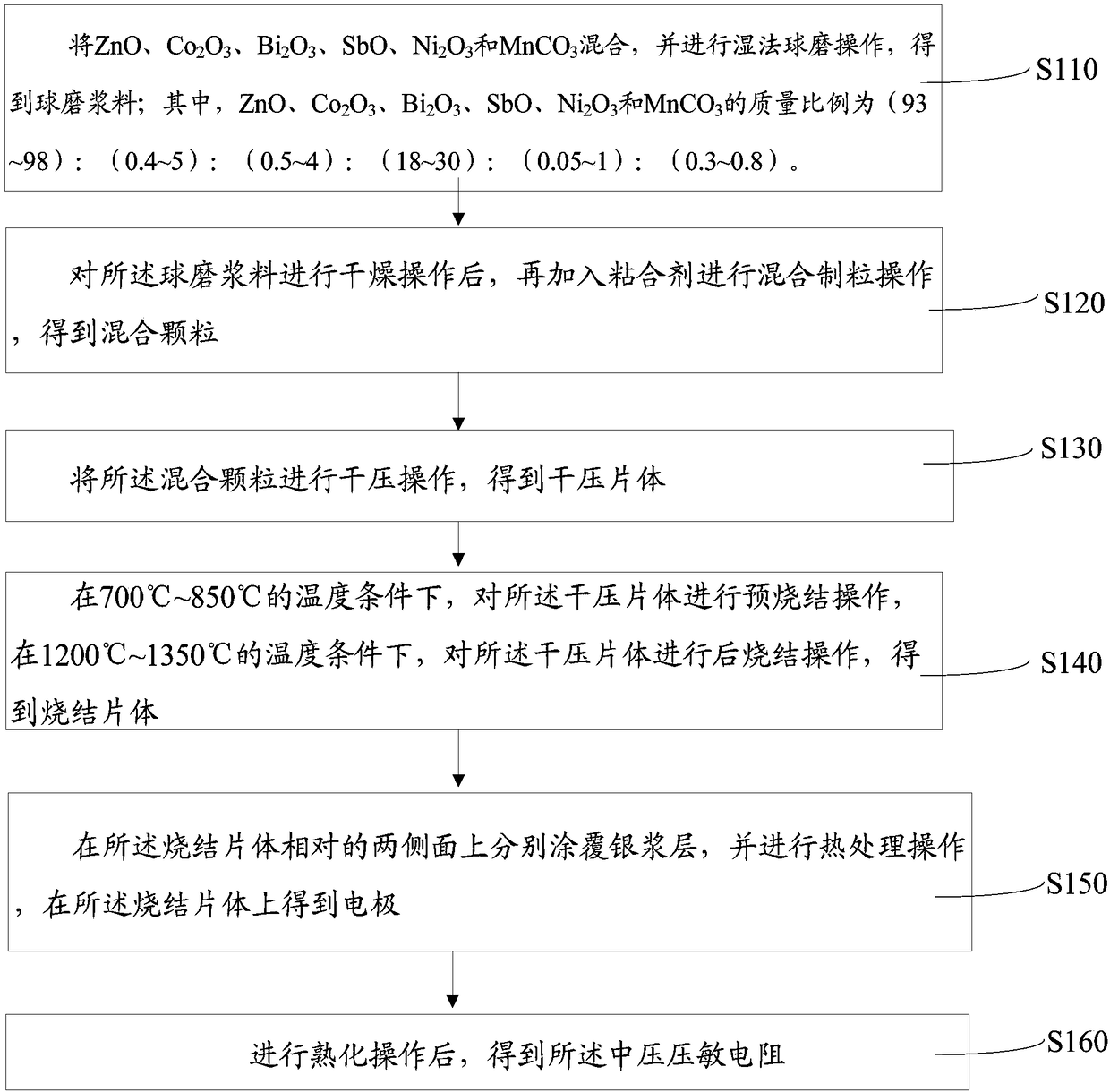

[0052] see figure 1 , the preparation method of the medium-voltage varistor of an embodiment, comprises the following steps:

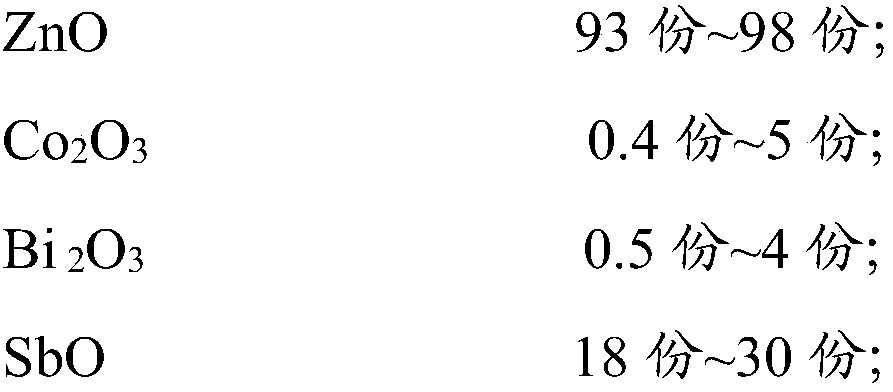

[0053] S110, ZnO, Co 2 o 3 、 Bi 2 o 3 , SbO, Ni 2 o 3 and MnCO 3 Mix, and carry out wet ball milling operation, obtain ball milling slurry; Wherein, ZnO, Co 2 o 3 、 Bi 2 o 3 , SbO, Ni 2 o 3 and MnCO 3 The mass ratio is (93~98):(0.4~5):(0.5~4):(18~30):(0.05~1):(0.3~0.8).

[0054] It should be noted that by combining ZnO, Co 2 o 3 、 Bi 2 o 3 , SbO, Ni 2 o 3 and MnCO 3 Mix according to the above ratio, and then use wet ball milling to obtain ball milled slurry. Specifically, ZnO, Co 2 o 3 、 Bi 2 o 3 , SbO, Ni 2 o 3 and MnCO 3 Place them in a grinding container according to the above ratio for mixing operation, and then use a wet ball mill to perform wet ball milling operation on the mixed materials in the grinding container. The wet ball mill adopts a special rolling bearing as the support structure of the cylinder. The mixed ...

Embodiment 1

[0081] 970gZnO, 50gCo 2 o 3 、40gBi 2 o 3 , 300gSbO, 10gNi 2 o 3 and 3gMnCO 3 Mixing, and performing a wet ball milling operation, the duration of the wet ball milling operation is 2 hours, thereby obtaining a ball milling slurry;

[0082] After drying the obtained ball mill slurry, adding a binder for mixing and granulation operation, the binder is polyvinyl alcohol, so as to obtain mixed granules;

[0083] Carrying out a dry pressing operation on the obtained mixed granules to obtain a dry compressed tablet;

[0084] Under the temperature condition of 750°C, pre-sinter the obtained dry compacted body for 2 hours. After the sintering operation, a sintered sheet is obtained;

[0085] Coating silver paste layers on opposite sides of the obtained sintered sheet respectively, and performing a heat treatment operation, so that electrodes are obtained on the sintered sheet;

[0086] The aging operation is carried out on the sintered sheet after the electrode is obtained, so...

Embodiment 2

[0089] 960gZnO, 40gCo 2 o 3 、30gBi 2 o 3 , 270gSbO, 5gNi 2 o 3 and 3.5gMnCO 3 Mixing, and performing a wet ball milling operation, the duration of the wet ball milling operation is 2 hours, thereby obtaining a ball milling slurry;

[0090] After drying the obtained ball mill slurry, adding a binder for mixing and granulation operation, the binder is polyvinyl alcohol, so as to obtain mixed granules;

[0091] Carrying out a dry pressing operation on the obtained mixed granules to obtain a dry compressed tablet;

[0092]Under the temperature condition of 750°C, pre-sinter the obtained dry compacted body for 2 hours. After the sintering operation, a sintered sheet is obtained;

[0093] Coating silver paste layers on opposite sides of the obtained sintered sheet respectively, and performing a heat treatment operation, so that electrodes are obtained on the sintered sheet;

[0094] The aging operation is carried out on the sintered sheet after the electrode is obtained, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com